Multiple product production mode statistical process control method based on T-K control chart

A technology of statistical process control and production mode, applied in general control system, control/regulation system, adaptive control, etc., can solve problems such as control chart performance degradation, false positive rate increase, abnormal cause insensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

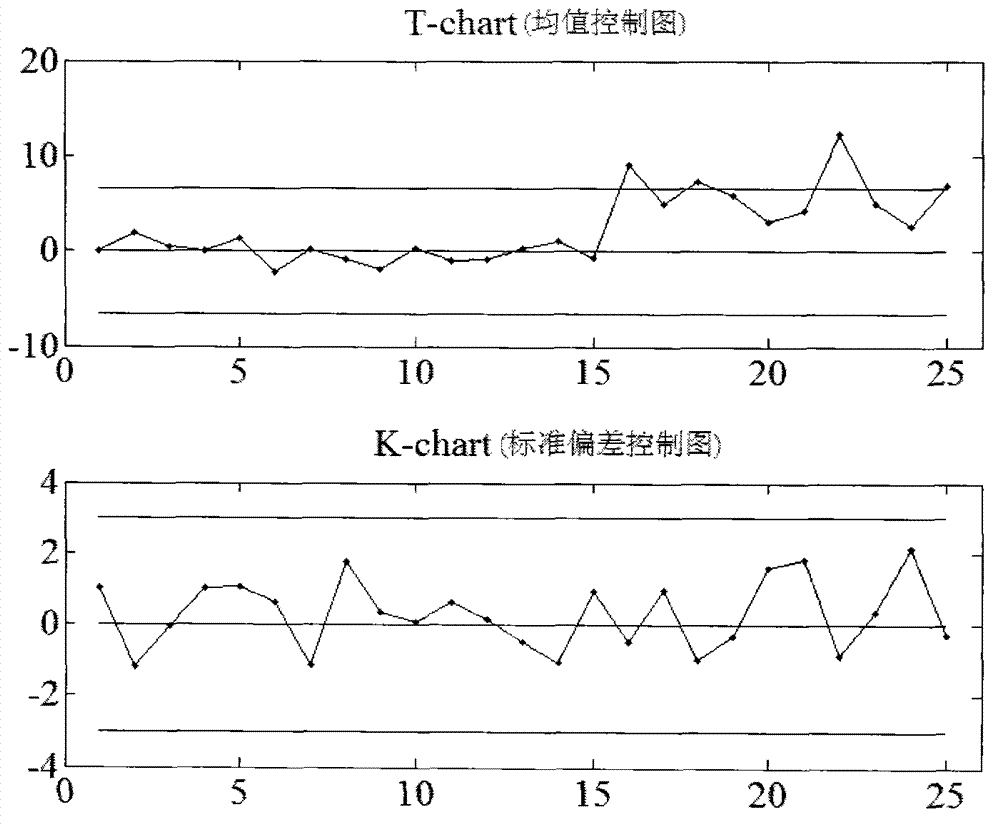

[0066] Embodiment 1. The ability of the T-K control chart to detect process mean out of control is verified by means of simulation. Use a random number generator to generate 25 batches of data, each batch of 5 samples, assuming that these 25 batches of data are composed of two types of products A and B, respectively subject to normal distribution N(10, 0.1) and N(20, 0.5) , when the random number is generated, the product type of each batch of samples is randomly determined with equal probability, assuming that the 1st to 15th batch of data is in a controlled state, starting from the 16th batch of data, the mean value of the two products has a shift of 3 times the standard deviation, The standard deviation has not changed, that is: the parameters of type A products obey N(10.3, 0.1), and the parameters of type B products obey N(21.5, 0.5). These 25 batches of data were analyzed using the T-K control chart, the results are as follows figure 1 .

[0067] Theoretically, the 1s...

Embodiment 2

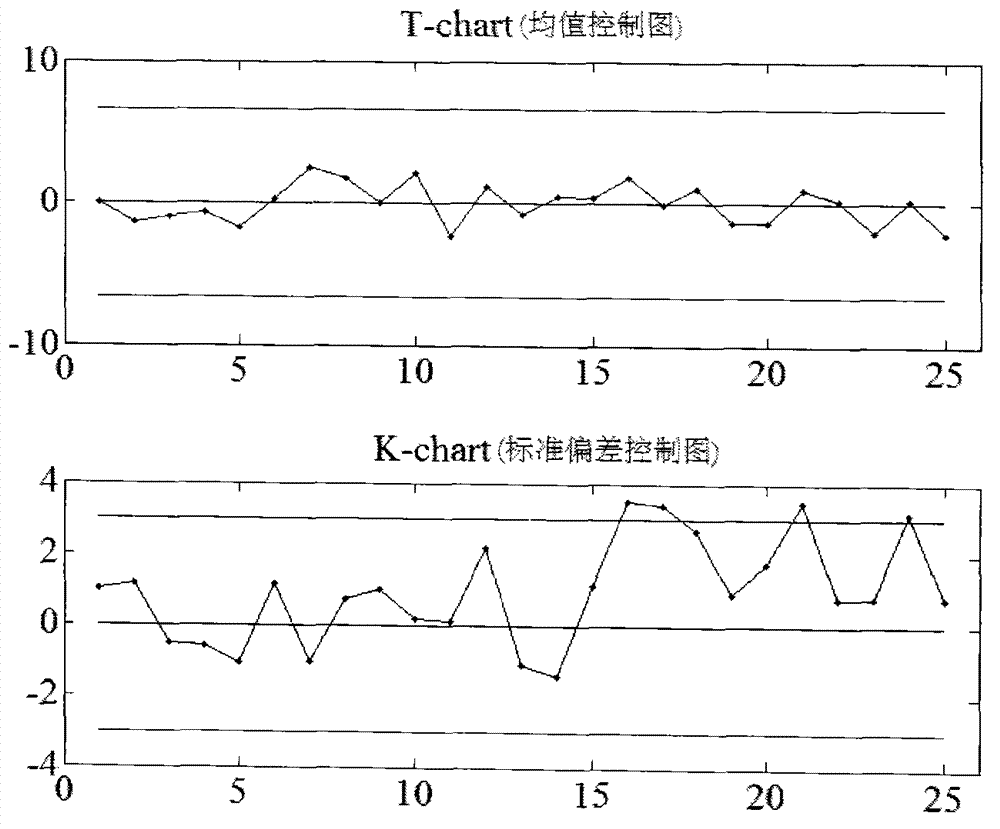

[0068] Example 2. Using simulation to verify the ability of the T-K control chart to detect process standard deviation out of control. The verification process is similar to Example 2. Use a random number generator to generate 25 batches of data, each batch of 5 samples, these 25 batches of data are composed of two types of products A and B, respectively subject to normal distribution N(10, 0.1) and N(20, 0.5), Assuming that the 1st to 15th batches of data are in a controlled state, starting from the 16th batch of data, the standard deviations of the two products are abnormally expanded to three times the original, while the mean value does not change, that is: the parameters of type A products obey N(10 , 0.3), B-type product parameters obey N (20, 1.5). The 25 batches of data were analyzed using the T-K control chart, and the results are shown in Figure 2. Theoretically, the mean value of these 25 batches of data has not shifted, so there should be no out-of-control points...

Embodiment 3

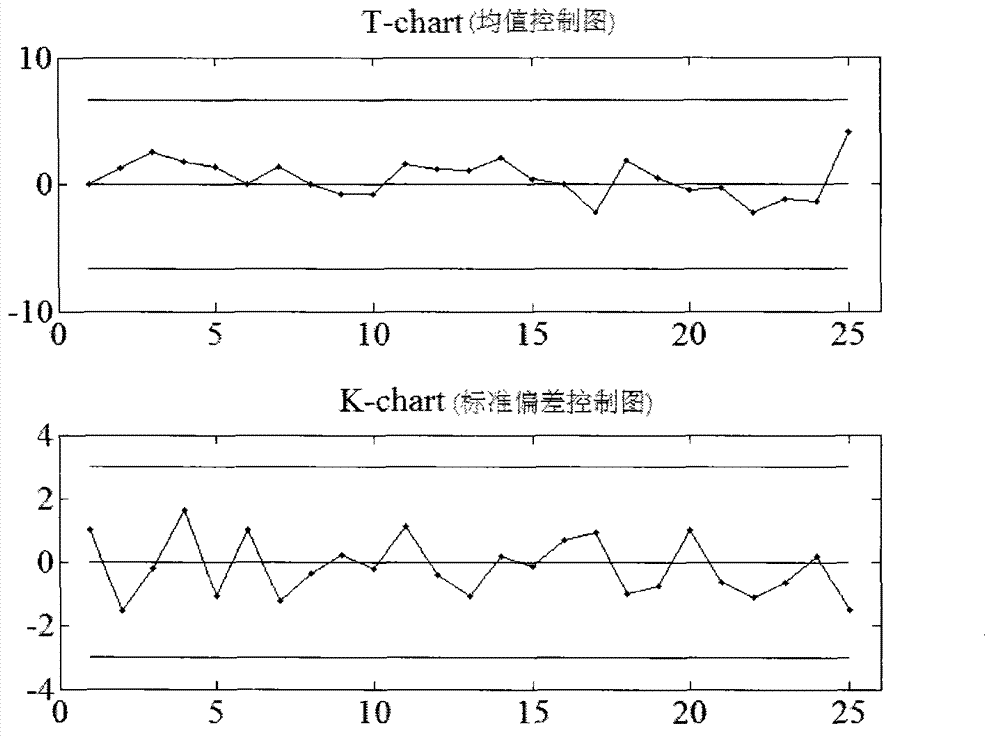

[0069] Example 3. Using T-K control chart to evaluate the operation state of the actual process. In the bonding process of microcircuit production, there are two types of bonding wires used, the models are F30 and F50. In the normal production process, a total of 25 batches of data were monitored, with 5 samples in each batch, and the T-K control chart was used for SPC analysis. The results are shown in Figure 3. The analysis results show that the bonding process is in a state of statistical control.

[0070] in conclusion

[0071] In the quality control of multi-variety production process, the traditional control chart technology cannot be directly used in multi-variety production environment due to insufficient data and different types of product process parameters do not obey the same normal distribution. This paper proposes the T-K control chart technology suitable for multi-variety production mode, including the definition and calculation method of T and K statistics, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com