Monitoring system used for blast furnace winding engine system and monitoring method thereof

A monitoring system and winch technology, applied in electrical testing/monitoring, comprehensive factory control, electrical program control, etc., can solve problems such as blast furnace production not running smoothly, wind reduction or even shutdown, waste of cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

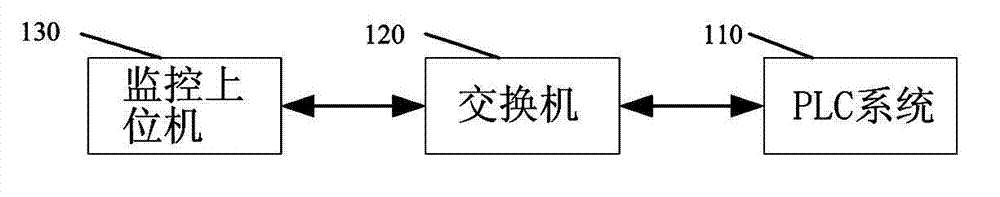

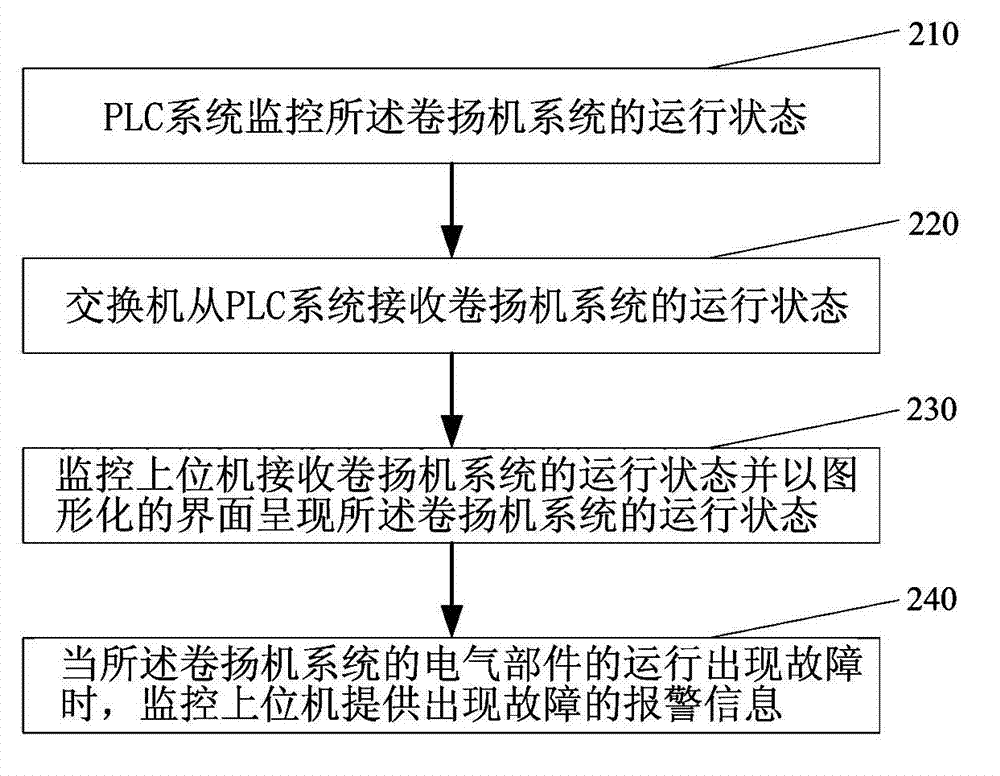

[0027] The monitoring system for the hoist system of the blast furnace according to the exemplary embodiment of the present invention intuitively provides the operation status of the hoist system of the blast furnace by presenting the operation status of the hoist system of the blast furnace through a graphical interface. Such as figure 1 as shown, figure 1 A block diagram showing a monitoring system for a hoist system of a blast furnace according to an exemplary embodiment of the present invention.

[0028] Such as figure 1 , the monitoring system for the blast furnace winch system may include a programmable logic controller (PLC) system 110 , a switch 120 and a monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com