Realization of control method and device for vacuum circuit breaker based on coil current

A vacuum circuit breaker and control method technology, applied in the direction of high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve problems such as limited number of measurements, limited application fields, and easy failures, and achieve convenient operation and stable measurement Good performance, weaken the effect of contact bouncing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

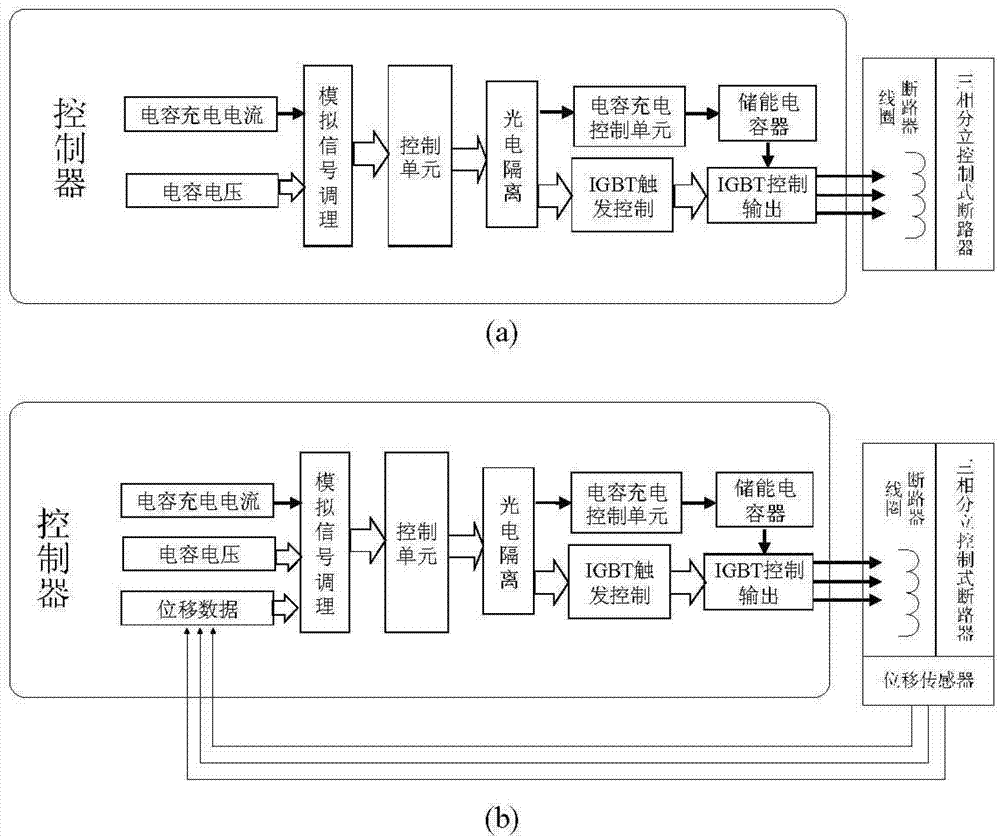

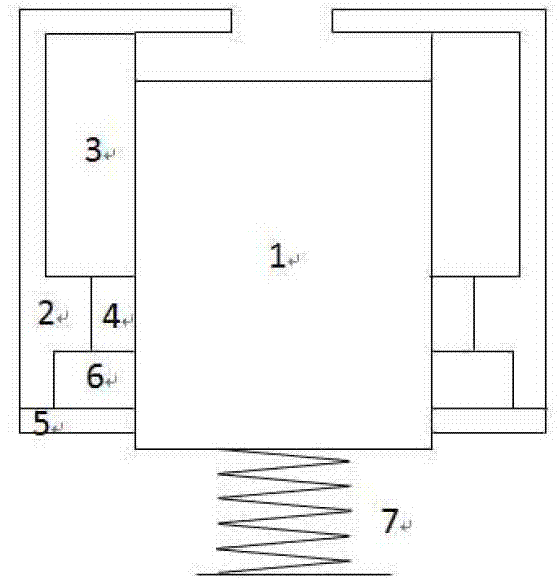

[0083] This example takes a three-phase discrete control 12kV vacuum circuit breaker as an example, and specifically illustrates the setting method of the reference coil current curve of the control device suitable for the circuit breaker.

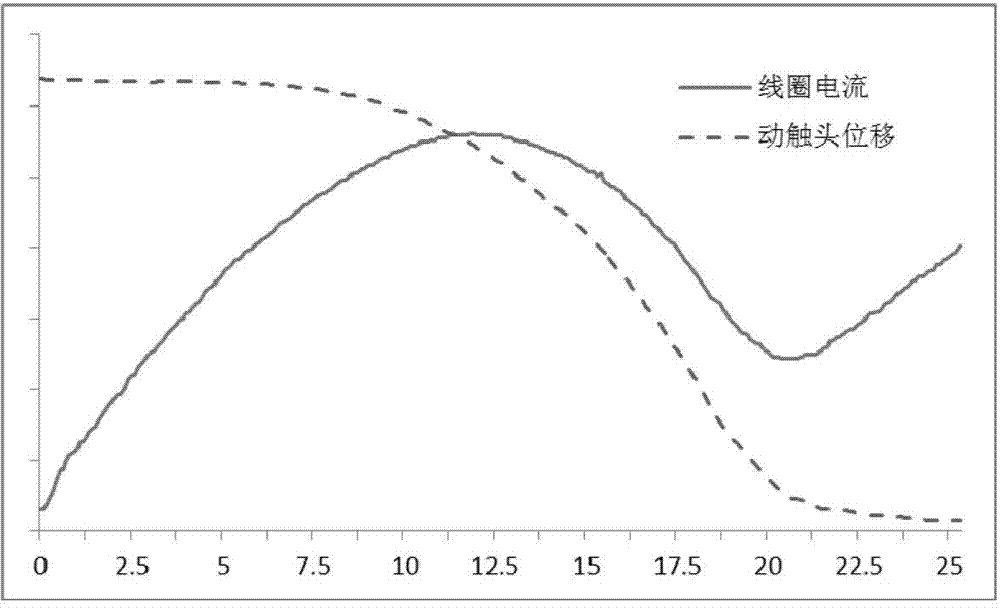

[0084] First, according to the parameters of the vacuum circuit breaker, the capacitance storage capacitors with capacitance values of 2500μF and 4700μF are respectively selected for the measurement of the open loop current curve in the control device. Picture 9 In the case of an energy storage capacitor with an initial voltage of 210V and a capacitance value of 2500μF, the dynamic characteristic curve of the circuit breaker includes current, displacement and speed curves when opening and closing control is performed according to the open-loop control principle; Picture 10 It is the dynamic characteristic curve of the circuit breaker in the case of an energy storage capacitor with an initial voltage of 170V and a capacitance of 4700μF. For ...

example 2

[0087] This example is used to verify the driving coil current curve control method based on the present invention, in which a 4700μF energy storage capacitor is selected for experiment. Picture 11 with Picture 12 The comparison of the coil current curve output by the control device and the reference current current curve, and the comparison of the displacement curve and the displacement curve corresponding to the reference current curve, are given when the capacitance value of the energy storage capacitor is 4700μF and the initial voltage and voltage are respectively 200V.

example 3

[0089] This example is used to verify the driving coil current curve control method based on the present invention, in which a 47000μF energy storage capacitor is selected for experiment. Figure 13 with Figure 14 The comparison of the coil current curve output by the control device with a capacitance of 47000μF and a voltage of 180V with the reference current curve and the displacement curve corresponding to the reference current curve are given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com