Thyristor module

A technology of thyristors and conductive blocks, which is applied in the field of power semiconductor module manufacturing, can solve the problems of pressing the shell, difficulty in realization, and many failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

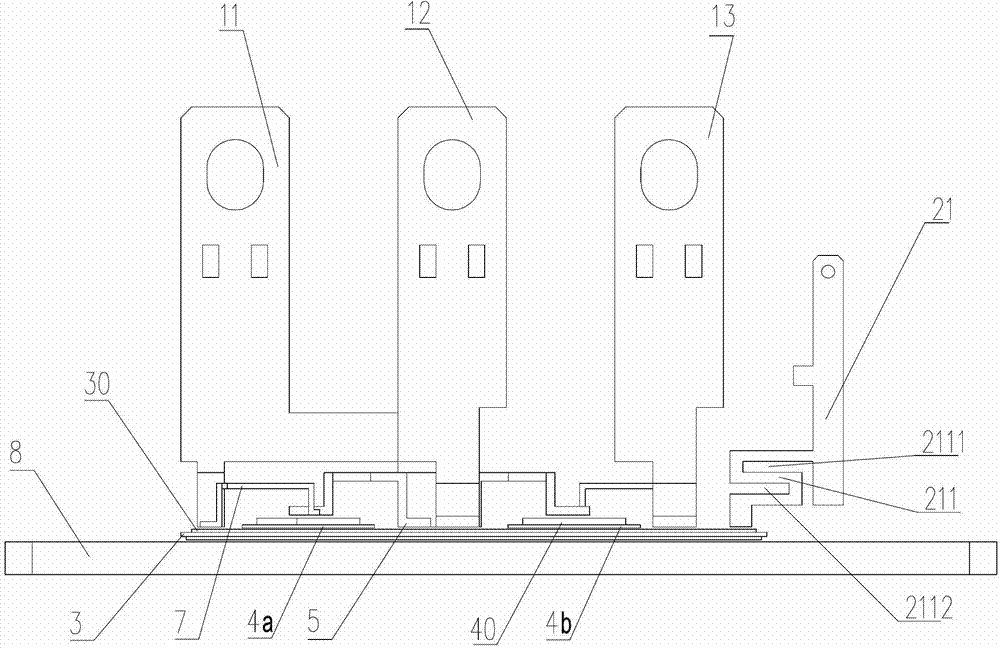

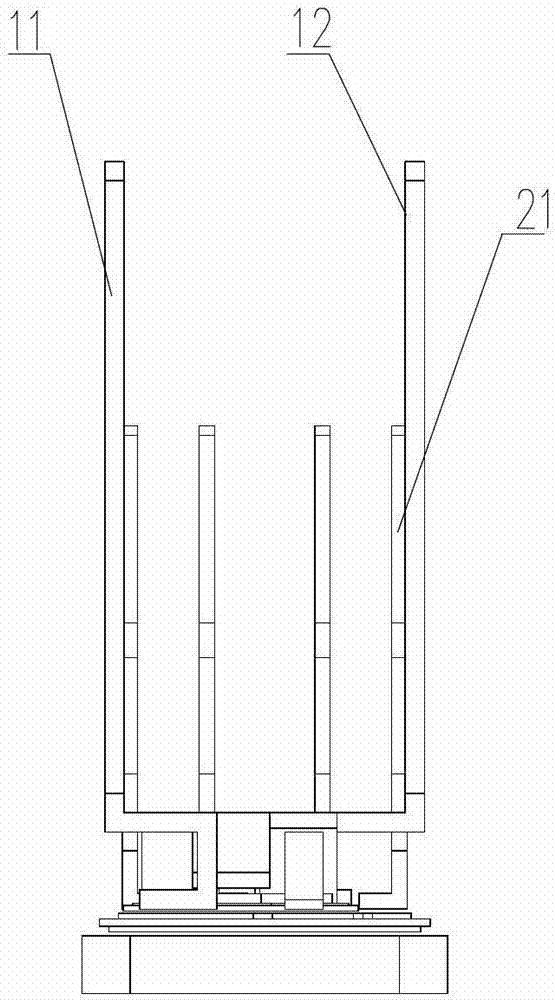

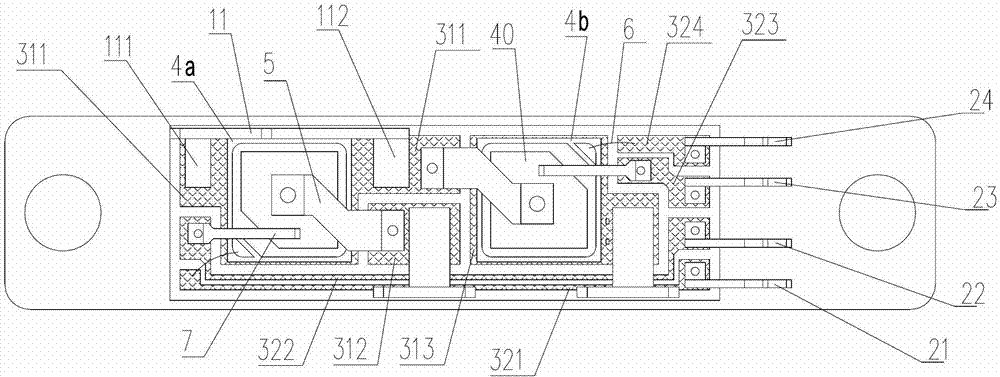

[0037] The present invention as Figure 1-6 As shown, it includes base plate, shell, substrate, chip one, chip two, electrode one, electrode two, electrode three, signal terminal Ga, signal terminal Ka, signal terminal Kb and signal terminal Gb; the fronts of the two chips are anodes A, the back is provided with a cathode K and a gate G; the top surface of the substrate is printed with mutually insulated conductive block area 1, conductive block area 2, conductive block area 3, conductive line area 1, conductive line area 2, conductive Line area three and conductive line area four;

[0038] The electrode 1, the anode A of the chip 1 and the cathode K of the chip 2 are connected to the conductive block area 1;

[0039] The electrode 2 and the cathode K of the chip 1 are connected to the conductive block area 2;

[0040] The electrode 3 and the anode A of the chip 2 are connected to the conductive block area 3;

[0041] The gate G of the chip 1 is connected to the conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com