Satellite-borne ferrite microwave front-end backup circuit

A ferrite, backup technology, applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of system complexity, weight increase, reliability reduction, etc., to solve the system is too complex, reduce equipment volume and weight, The effect of meeting the requirements of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

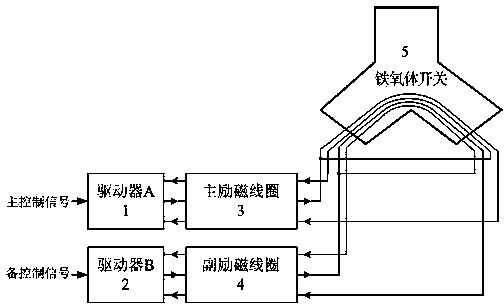

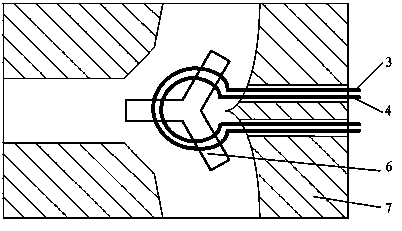

[0013] A spaceborne ferrite microwave front-end backup circuit, including: driver A1, driver B2, also includes: main excitation coil 3, auxiliary excitation coil 4, ferrite switch 5, wherein the ferrite switch 5 includes: ferrite Magnetic core 6 and cavity 7.

[0014] The cavity 7 of the ferrite switch 5 is a rectangular parallelepiped metal piece with a "Y" shaped cavity inside, and the ferrite core 6 is "Y" shaped, placed in the center of the "Y" shaped cavity, and connected to the cavity 7 glued in between. There are through holes on the three arms of the ferrite core 6, and there are two through holes on one side of the cavity 7. The main excitation coil 3 and the auxiliary excitation coil 4 pass through the three arms of the ferrite core 6 in parallel. Through holes on the arm, the two ends of the coil pass through the two through holes of the cavity 7 respectively. The output end of the driver A1 is connected to the main exciting coil 3 , and the output end of the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com