Moving device of pull head

A technology of moving devices and sliders, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high price and complicated structure, and achieve the effect of cheap price and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

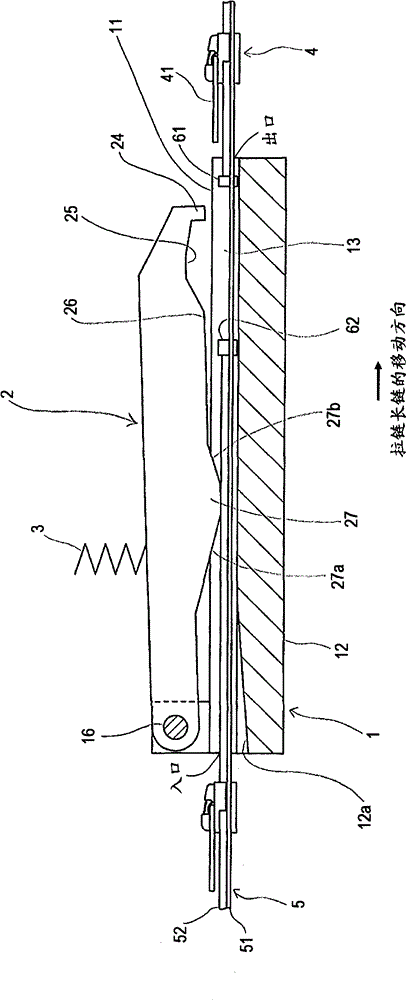

[0098] Hereinafter, embodiments of the slider moving device of the present invention will be described in detail with reference to the drawings. Hereinafter, unless otherwise specified, the "upstream side" means the upstream side in the conveying direction of the fastener chain, and the "downstream side" means the downstream side in the conveying direction of the fastener chain.

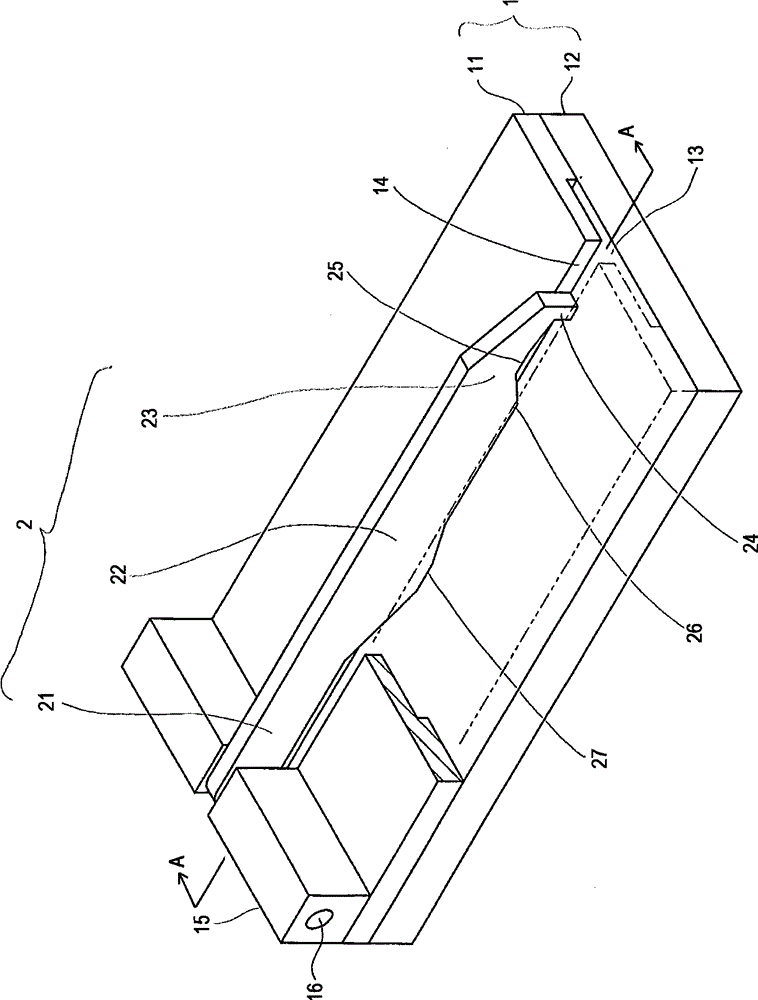

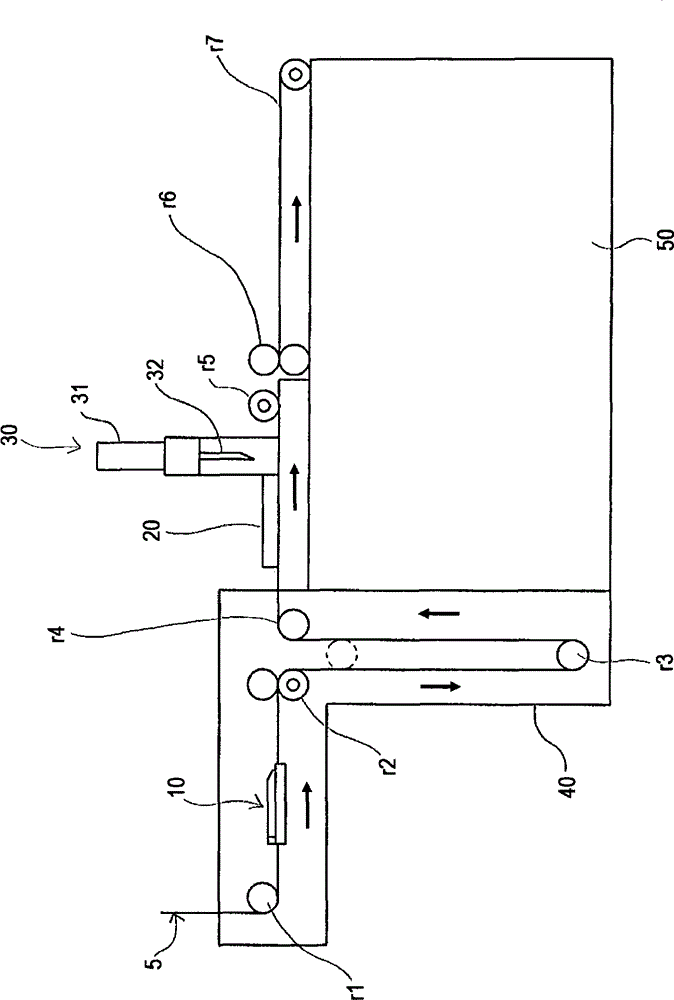

[0099] figure 1 Is a perspective view of the slider moving device 10, figure 2 It is a schematic front view showing an example of a zipper manufacturing device using the slider moving device 10.

[0100] Such as figure 2 As shown, in the slide fastener manufacturing apparatus, as indicated by the arrow, the long slide fastener chain is conveyed from the left side to the right side in the figure. In this manufacturing device, a guide roller r1, a slider moving device 10, a driving roller r2, a floating roller r3, a guide roller r4, a chain positioning unit 20, a cutting device 30, a driving roller r5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com