Buggy ladle with navigation bracket

A technology for ladle cars and navigation racks, which is applied to casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of high energy consumption, complex plate hook guide equipment, high production costs, etc., and achieve low energy consumption and eliminate Potential safety hazards and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

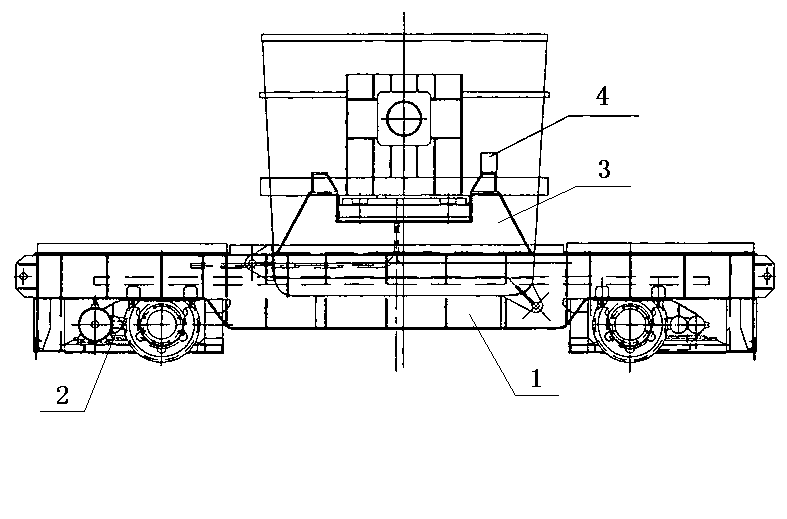

[0011] according to figure 1 As shown, the present invention has a ladle car with a navigation frame, including a car body 1, a walking transmission device 2, a synchronous lifting transmission mechanism and a ladle car seat frame 3, and the described walking transmission device 2, synchronous lifting transmission mechanism and steel Ladle car seat frames 3 are arranged on the car body 1 respectively, and a ladle car navigation frame 4 is arranged on the right side of the ladle car seat frames 3 .

[0012] The embodiment is only for the convenience of understanding the technical solution of the present invention, and does not constitute a limitation to the protection scope of the present invention. Any simple modification, equivalent change and Modifications still fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com