Cutting knife

A technology of cutting knives and blades, which is applied in metal processing and other directions, can solve the problems of inconvenient processing, inconvenience, trouble, etc., and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A cutting knife includes a knife head and a knife handle.

[0052] In this embodiment, the knife head and the knife handle are pivotally connected. During specific implementation, the knife head can also be telescopically connected to the knife handle, which is not limited in this embodiment.

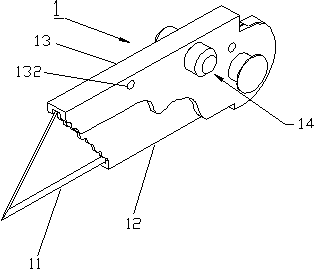

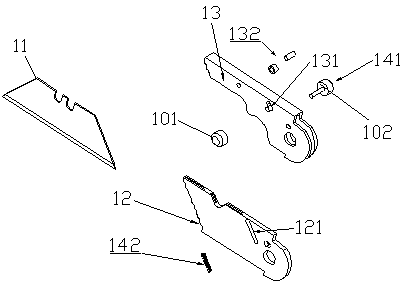

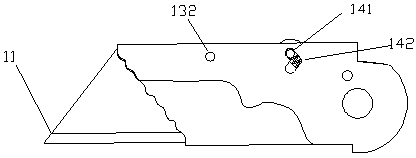

[0053] In this example, if figure 1 , the cutter head 1 includes a blade holder 12 for loading a blade 11, a base frame 13, and a first locking / unlocking device 14 for locking / unlocking the blade 11; Even; the first locking / unlocking device 14 is disposed between the blade seat 12 and the base frame 13 .

[0054] like figure 2 , the first locking / unlocking device 14 includes a toggle button 141 and a first elastic element. In this embodiment, the toggle knob 141 includes a first assembly 101 and a second assembly 102 ; the first elastic element is a compression spring 142 . During specific implementation, the types of the dial knob and the first elastic element can also ha...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that the tool handle 2 includes a second locking / unlocking device 21 for locking / unlocking the tool head. For details, see Figure 5 , Image 6 and Figure 7 .

[0064] The second locking / unlocking device 21 includes a push button 211, a second elastic element 212 and a skeleton structure 22. In this embodiment, the skeleton structure 22 includes an upper skeleton 201 and a lower skeleton 202, and the push button 211 is symmetrical on both sides. Protrusions are provided, and the upper frame 201 and the lower frame 202 are symmetrically provided with limiting through holes 221 and 222 for accommodating the protrusions. In this embodiment, the second elastic element is two torsion springs 212, one end of each torsion spring is connected to the end of the push button 211, and the other end is connected to the skeleton structure, and the two torsion springs are arranged symmetrically. During specific implementat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap