Multi-station automatic thermal transfer printer

A thermal transfer machine, multi-station technology, applied in the direction of rotary printing machine, printing machine, transfer printing, etc., can solve the problem of not being able to detect and discharge in time, feeding and unloading cannot be carried out at the same time, and the operation time is prolonged, etc. problems, to achieve the effect of convenient discovery and processing, compact steps, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

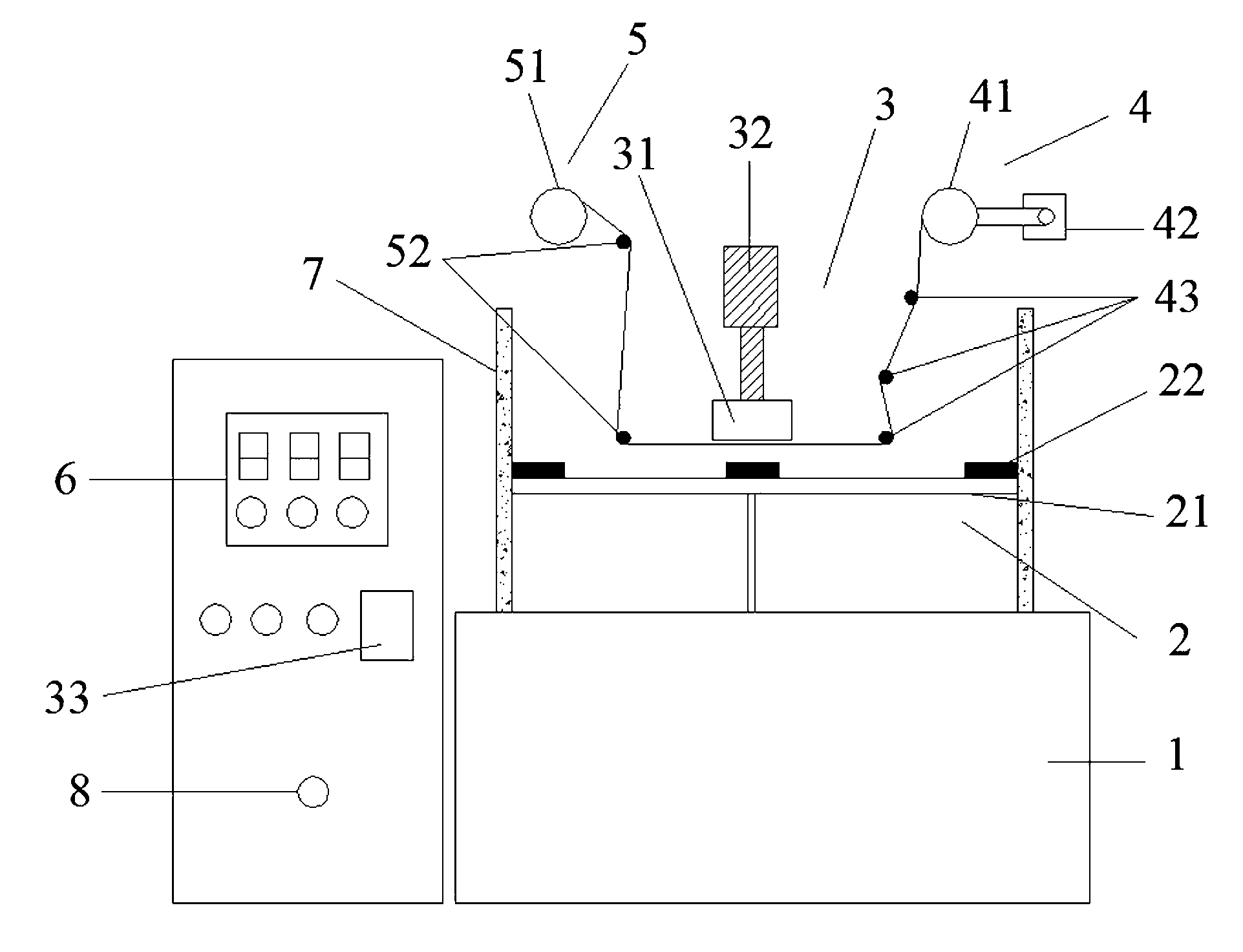

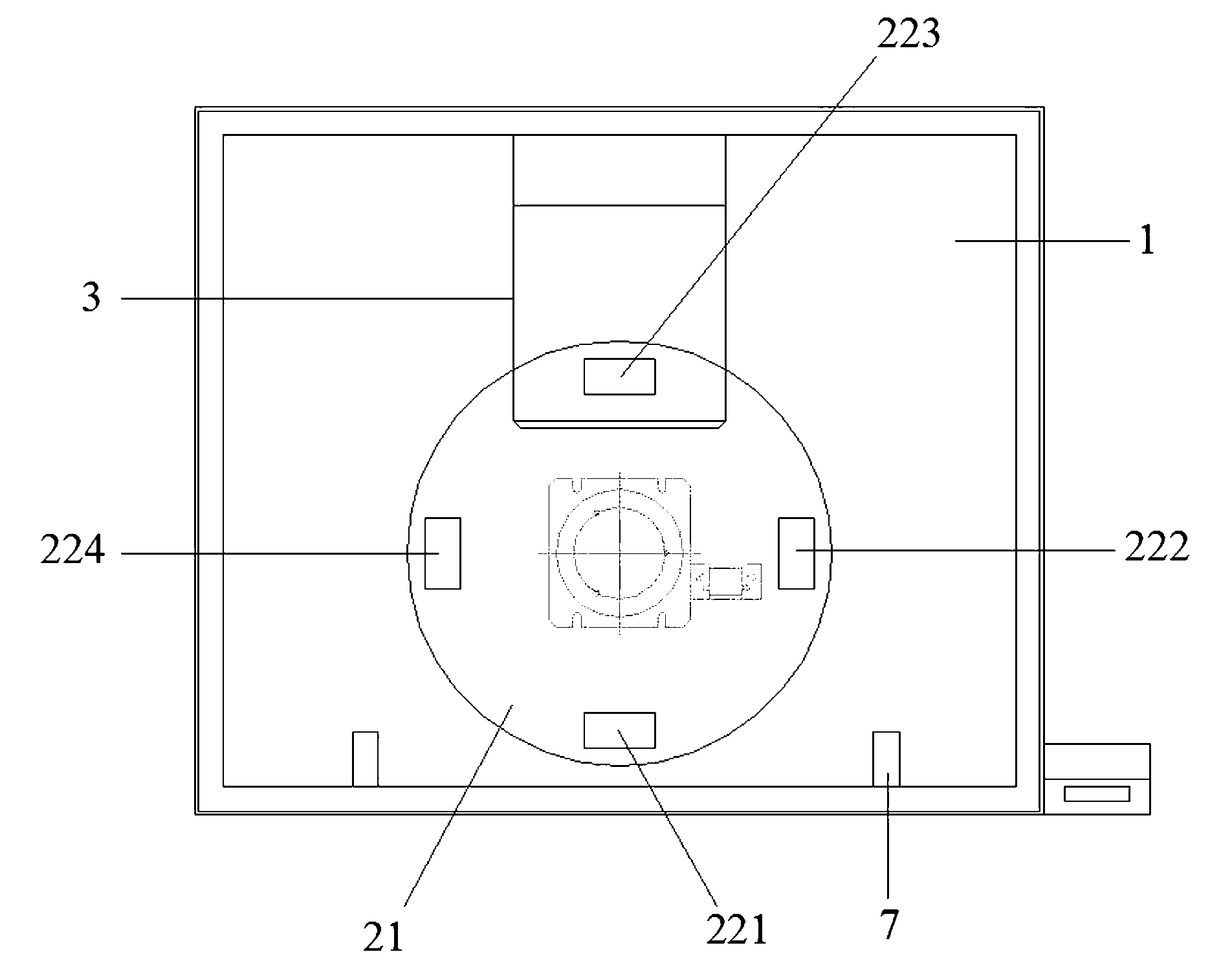

[0018] refer to figure 1 , the multi-station automatic heat transfer machine of the present invention comprises: a machine platform 1, a material conveying mechanism 2 arranged on the machine platform 1, a heat transfer mechanism 3 arranged above the material conveying mechanism 2, and a heat transfer mechanism 3 arranged on the heat transfer mechanism 3 The receiving and discharging mechanism on both sides, and the control mechanism 6 for controlling the work of the above-mentioned mechanisms. Wherein, the material conveying mechanism 2 includes: an indexing plate 21 , and a loading station 22 arranged on the front of the indexing plate 21 .

[0019] The working process of the thermal transfer printing machine of the present invention is as follows: when the workpiece to be processed is placed on the loading station 22, the index plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com