Saline-alkali reoccurrence preventing agent prepared from iron tailings, and application thereof in saline-alkali land

A technology for iron tailings and saline-alkali agents, which can be applied in application, land preparation methods, and other chemical processes, etc., can solve problems such as secondary environmental pollution, and achieve the effect of increasing grain output and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Location: Longwang, Nong'an, Jilin Province, 1 Changdi

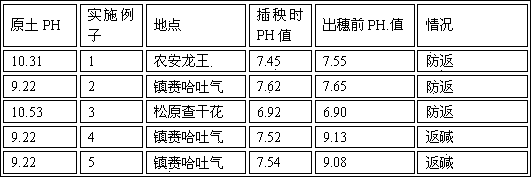

[0026] 1) First, measure the salinity of the paddy field that has been soaked in water, and the measured pH=10.31;

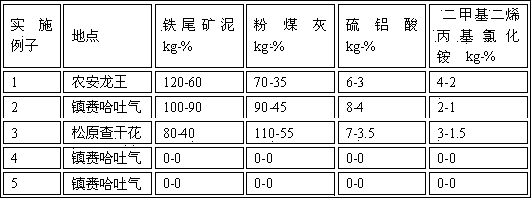

[0027] 2) According to the alkalization pH value in the paddy field, the amount of anti-saline-alkali agent required for saline-alkali land is 200kg per 1 垧 of anti-saline-alkali agent; that is, 120kg of iron tailings sludge, accounting for 60% of the weight ratio %, 70kg of fly ash accounts for 35% of the weight ratio, 6kg of aluminum sulfate accounts for 3% of the weight ratio and 4kg of dimethyl diallyl ammonium chloride accounts for 2% of the weight ratio;

[0028] 3) Sprinkle 200 kg saline-alkali land anti-salinization agent evenly on the surface of the paddy field, and immediately use a tractor plow to break up the wet soil and level the soil for stirring. The pH measured after two months is 7.55, basically no Back to alkali, output 6000kg.

Embodiment 2

[0029] Embodiment 2: implementation method is the same as embodiment 1

[0030] Location, Zhenlaiha, Jilin Province,

[0031] The measured pH=9.32, according to the alkalinity pH value in the paddy field, the amount of anti-saline-alkali agent for saline-alkali land is 200kg per 1 m, that is, 100kg of iron tailings sludge (50 %), 90kg of fly ash (45%), 8kg of aluminum sulfate (4%), 2kg of dimethyl diallyl ammonium chloride (1%), the measured pH=7.55 after two months, basically no return Alkali, output 14000kg.

Embodiment 3

[0032] Embodiment 3: implementation method is the same as embodiment 1

[0033] Place, Jilin Province Songyuan Cha dried flowers, implementation method is the same as embodiment 1,

[0034] Measured pH = 10.35, 1 垧, time May 28, 2011

[0035] According to the pH value of the alkalization degree in the paddy field, the amount of anti-saline-alkali agent for saline-alkali land is 200kg per 1 垧. The difference is that iron tailings sludge is 80kg (40%), powder Coal ash 110kg (55%), sulfoaluminic acid 7kg (3.5%), dimethyl diallyl ammonium chloride 3kg (1.5%), the measured pH=9.32 after two months, basically no return to alkali, the output 7000kg.

[0036] Examples are listed as follows for convenience:

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com