Three-top gas online desulphurization and pressurizing utilization method of atmospheric and vacuum distillation unit

A technology of atmospheric and vacuum device and head gas, applied in separation methods, chemical instruments and methods, hydrogen sulfide, etc., can solve the problems of unsolved hydrogen sulfide, peramine liquid foaming, unreachable, etc., and achieve no-circulation cooling The effect of low water consumption, low consumption of amine solution and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

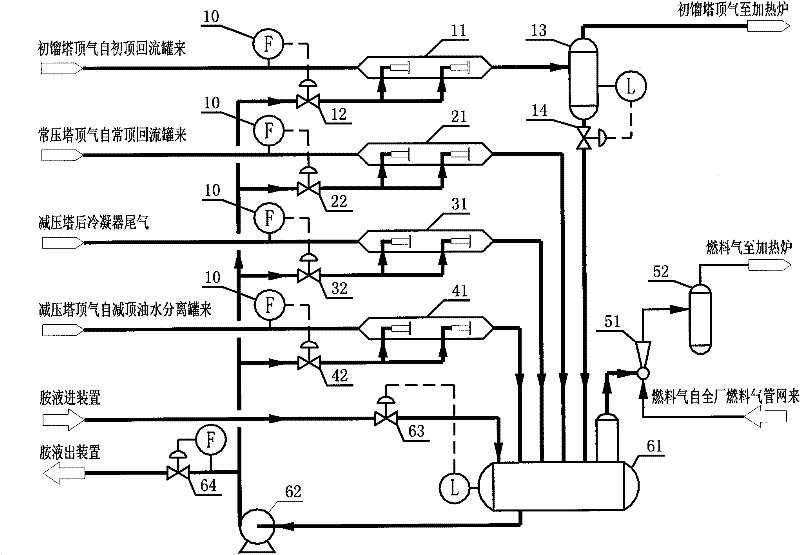

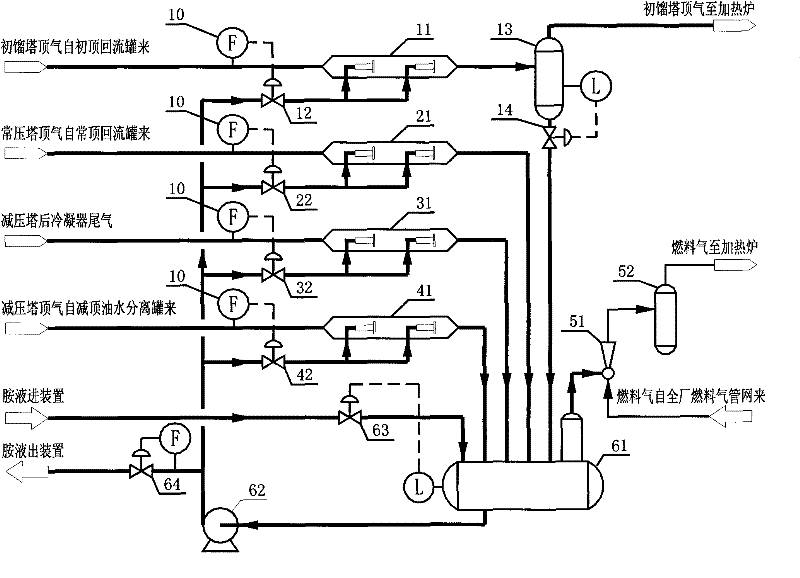

[0023] The present invention adopts the preferred mode: firstly, utilizes the discharge pressure of the top gas of the primary distillation tower, adds on-line desulfurization and gas-liquid separation processes, and directly serves as fuel gas for the heating furnace of the device after reaching the standard. The second is to carry out separate online desulfurization treatment on the atmospheric pressure tower top gas, vacuum tower top gas and post-condenser tail gas respectively. The 300-600kPa (absolute) fuel gas used in the atmospheric pressure furnace and the decompression furnace is used as the working fluid, and the purified gas separated from the amine liquid tank is drained by the injector, mixed with the fuel gas, pressurized, and then enters the heating furnace of the atmospheric and decompression device Burn, and keep the pressure of the amine liquid tank at a slight negative pressure. The specific implementation is as follows:

[0024] 1. On-line desulfurization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com