Gas liquid convection-type water and salt separator

A separation device and gas-liquid technology, which are applied in the field of gas-liquid convection type water-salt separation devices, can solve the problems of inability to collect and extract salt from fresh water, low efficiency, etc., and achieve the effects of simple manufacturing, high efficiency and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

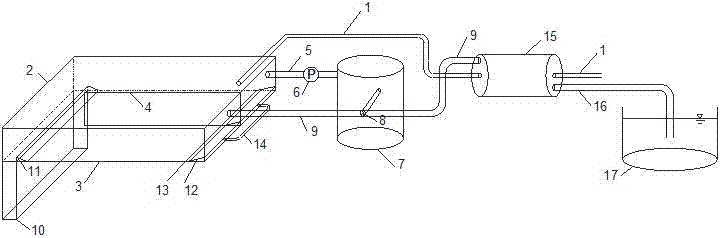

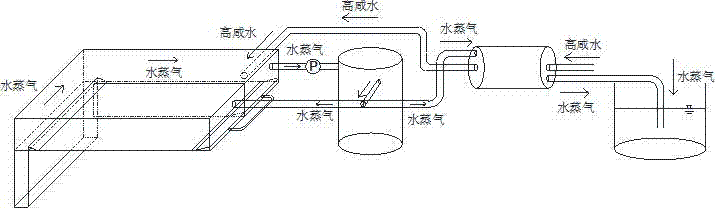

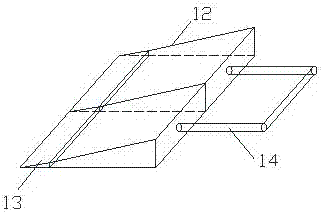

[0019] Such as figure 1 As shown (just an example, obviously there are many variations), a gas-liquid convection type water-salt separation device, including a water inlet pipe 1, an evaporation and gas-liquid convection glass box 2, an exhaust pipe 5, and an adiabatic steam cylinder 7 , air return pipe 9, cooling water jacket 15, air delivery pipe 16, fresh water tank 17; the evaporation and gas-liquid convection glass box 2 is provided with a black pottery bottom plate 3, and a dividing plate 4 is arranged perpendicular to the black pottery bottom plate to evaporate and gas-liquid convection The glass box 2 is evenly divided into front and rear chambers, and the tails of the two chambers are connected. The water inlet pipe 1 is connected to the rear chamber after passing through the cooling water jacket 15. There is an air extraction pump 6, and the air extraction pump 6 is used to extract the hot steam from the back room into the heat-insulating steam cylinder 7. The heat-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com