Energy-saving refrigerator

A technology outside refrigerators and refrigerators, applied in household refrigerators, coolers, lighting and heating equipment, etc., can solve problems such as low heat dissipation efficiency and increased heat leakage from condensation pipes, achieving low production costs, reduced heat leakage, and easy production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

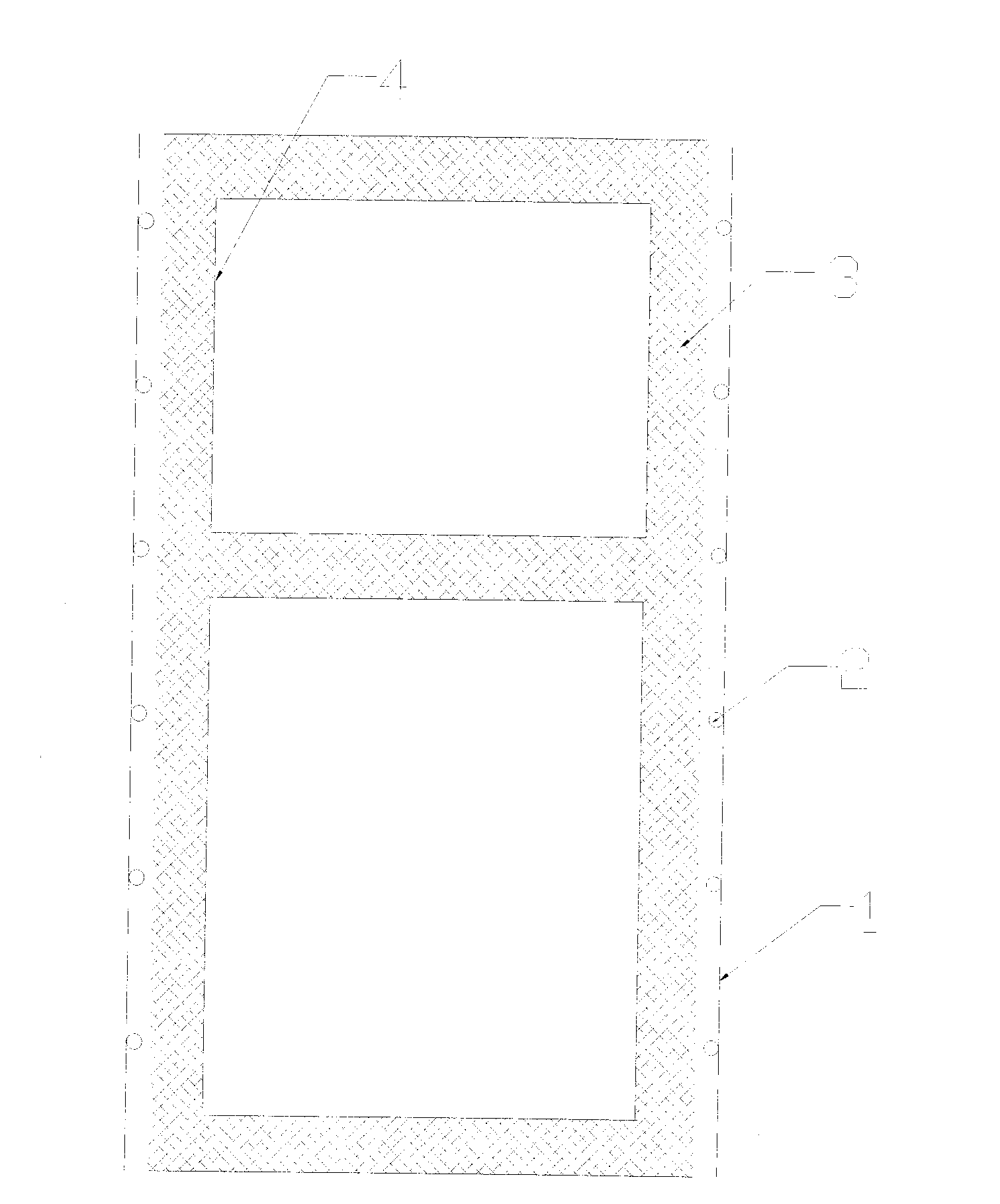

[0019] figure 1 Among them, 1 is the outer box wall of the refrigerator, 2 is the condensing pipe of the refrigerator condenser, 3 is the insulation layer of the refrigerator, and 4 is the inner tank of the refrigerator. In this embodiment, the outer box wall 1 of the refrigerator is not in direct contact with the insulation layer 3 of the refrigerator, and the outer box wall 1 of the refrigerator and the condensation pipe 2 of the refrigerator condenser form a refrigerator condenser.

[0020] In this embodiment, there is an air channel from bottom to top between the outer box wall 1 of the refrigerator and the insulation layer 3 of the refrigerator. The air in the air channel circulates naturally with the air in the environment. Heat exchange with the environment through the air channel increases the heat exchange area of the condenser and enhances the heat exchange effect.

Embodiment 2

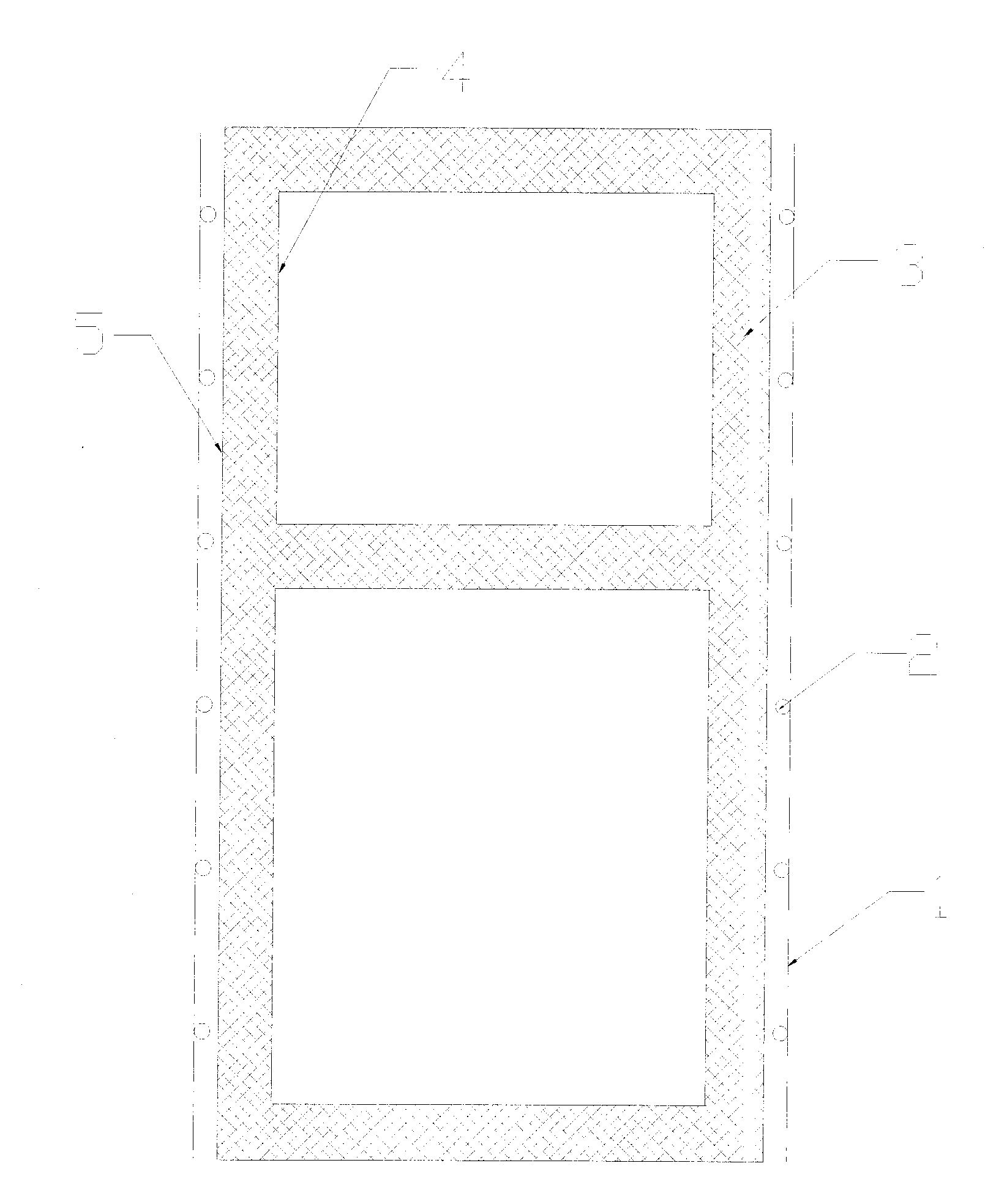

[0022] figure 2 It is the structure of embodiment 2, in the figure 1 is the outer box wall of the refrigerator, 2 is the condensing pipe of the refrigerator condenser, 3 is the insulation layer of the refrigerator, 4 is the refrigerator liner, and 5 is the baffle. Compared with Embodiment 1, a baffle 5 is added in this embodiment.

[0023] In this embodiment, there is little change in structure relative to Embodiment 1, mainly based on the consideration of production convenience. Inject between the baffle plate 5 and the refrigerator liner 4, and then install the refrigerator outer case wall 1 and the refrigerator condenser condensation tube. You can also put the refrigerator outer box wall

[0024] 1. Refrigerator condenser Condenser tube 2 and baffle plate 5 are assembled into a condenser; then the condenser is integrated with refrigerator liner 4, and heat insulating material is filled into it.

Embodiment 3

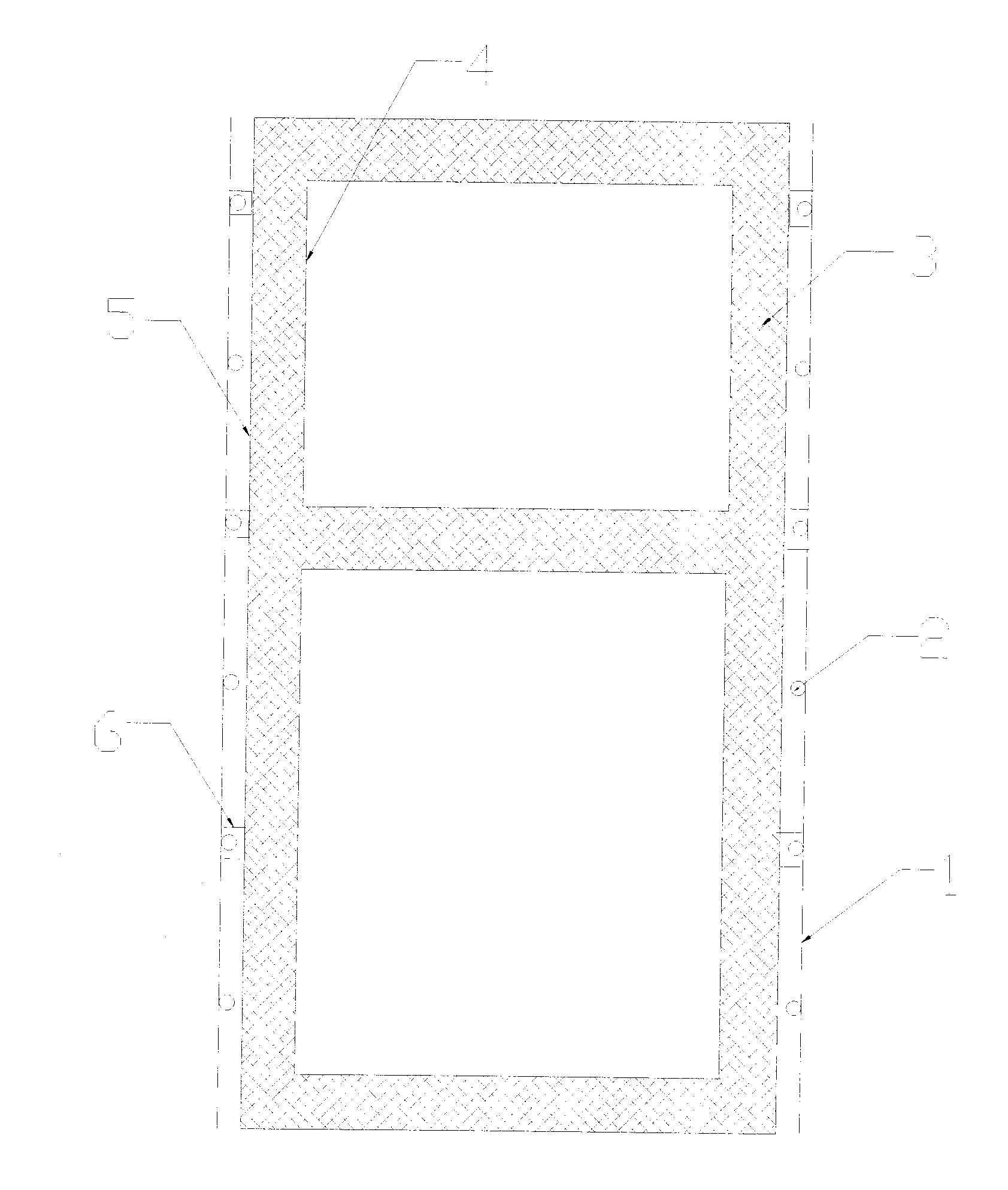

[0026] image 3 It is the structure of embodiment 3, in the figure 1 is the outer box wall of the refrigerator, 2 is the condensation pipe of the refrigerator condenser, 3 is the insulation layer of the refrigerator, 4 is the refrigerator liner, 5 is the baffle plate, and 6 is the filler. In this embodiment, a small amount of filler is filled between the refrigerator outer box wall 1 and the baffle plate 5 .

[0027] Compared with Example 2, this example adds a small amount of filler 6 in structure. The purpose of adding filler 6 is mainly to fix the position between the refrigerator outer box wall 1 and the baffle 5, and prevent the refrigerator from foaming or using. It is deformed due to the extrusion of external force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com