Method and device for detecting frictional characteristics of strengthened curved surface

A technology of friction characteristics and strengthening treatment, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of result errors, cumbersome data processing, and the inability to obtain the distribution of friction coefficient on curved surfaces, etc., to eliminate the influence and make the experimental data reliable. letter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

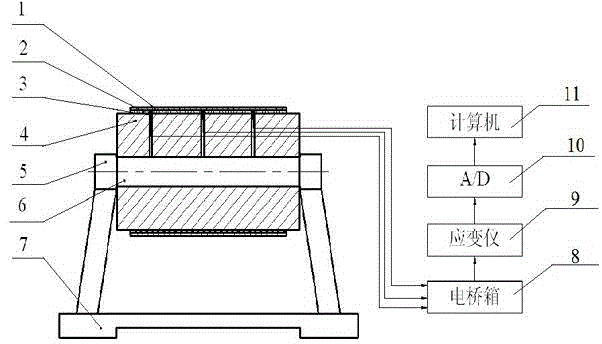

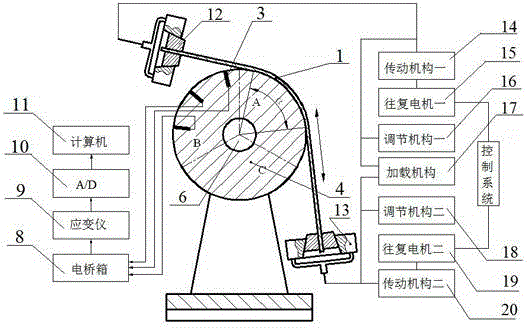

[0031] Combine below figure 1 and figure 2 Describe in detail the specific details and working conditions of the proposed device of the present invention.

[0032] First, surface treatment is carried out on the surface of the selected cylindrical roller 4. In this example, the surface of the roller 4 is subjected to laser roughening treatment. Using laser equipment, after selecting appropriate laser processing parameters, implement laser texturing with different topography schemes on different areas on the roller 4, such as figure 2 As shown, it is implemented on the surface of three different regions A, B, and C. After obtaining the desired textured appearance, install the roller 4 on the bracket 5, place the metal sheet 1 on the area A, and clamp the two ends of the metal sheet 1 by the clamping device 12 and the clamping device 13 . Adjust the clamping device 12 through the auxiliary adjustment mechanism 1, adjust the position of the clamping device 13 in two directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com