Flat high-speed cable production method and products thereof

A cable and high-speed technology, applied in the field of cable preparation, can solve problems such as filling defects, out-of-round stranding, attenuation, etc., and achieve the effects of improving performance stability, reducing strand stress, and reducing bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a flat high-speed cable provided in this embodiment includes the following steps:

[0044] 1) Prepare the semi-finished flat high-speed cable to be processed:

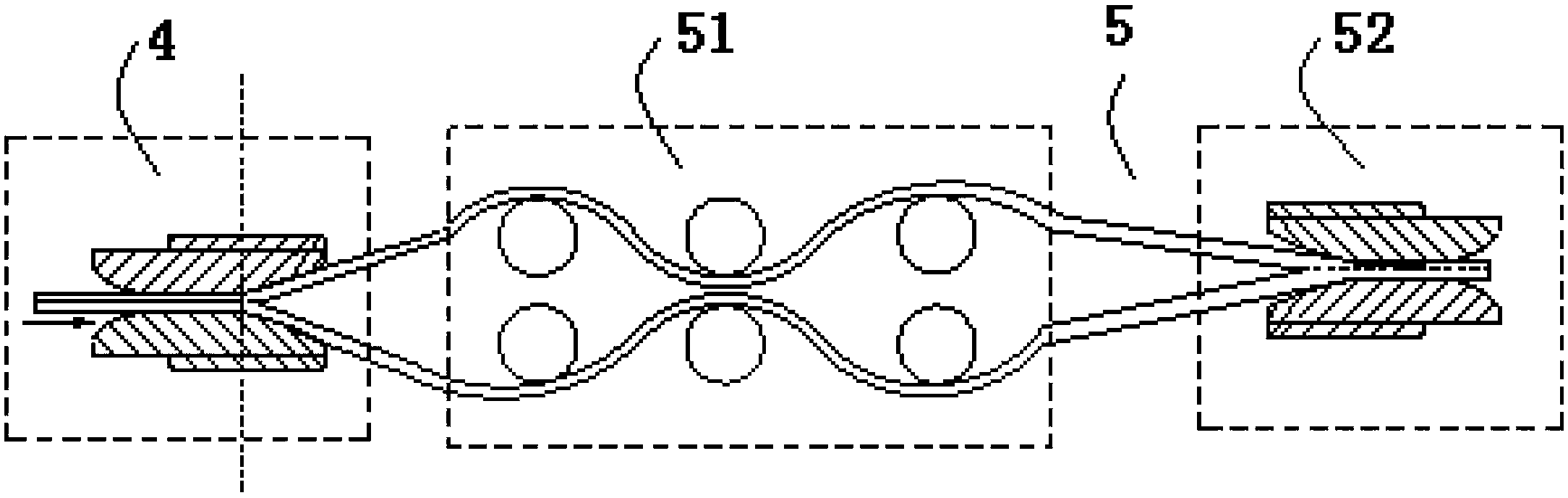

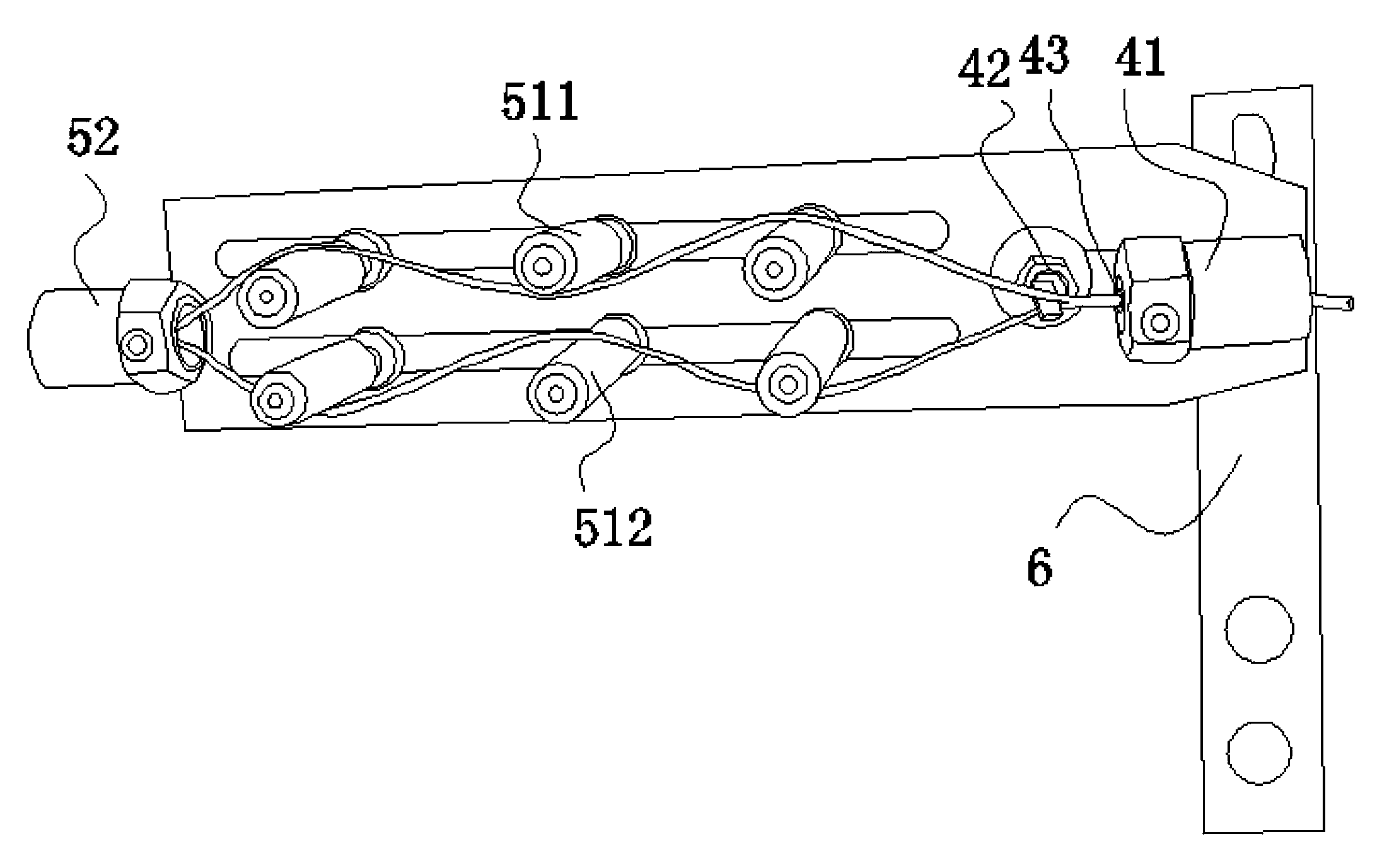

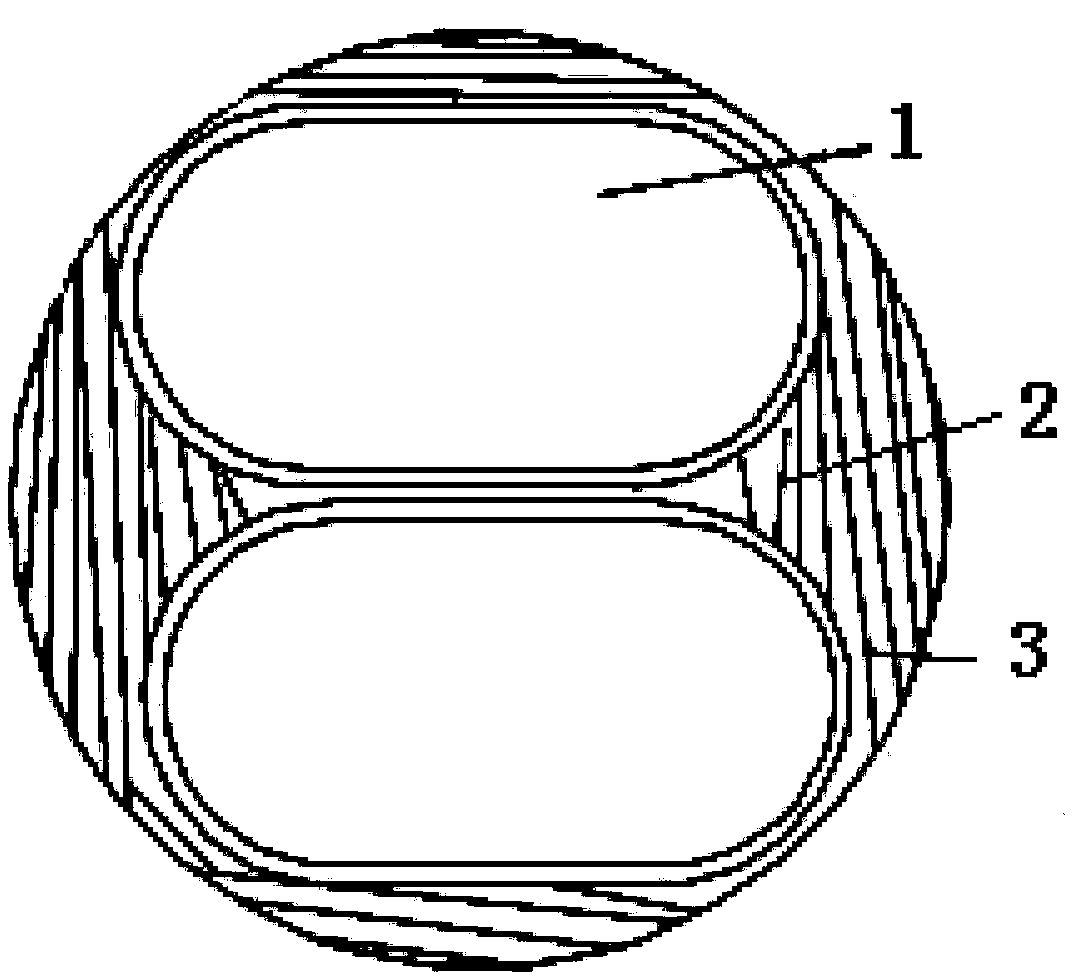

[0045] 1.1) Betting in the middle: according to the preset, arrange the pairs of high-speed flat signals 1 in pairs along the center line of a circle, so that the cross-sections of the high-speed flat signal pairs 1 are evenly and symmetrically distributed on the circle; Extrude a round center-quilted flat high-speed cable through a cable extrusion mold, and the center-quilted flat high-speed cable 1 is formed with a gap filling layer 2 and an outer covering layer 3 to ensure that the gap between the high-speed flat signal pair 1 is effectively fill and effectively cover the exterior;

[0046] 1.2) Forming a semi-finished flat high-speed cable: on the outer edge of the flat high-speed cable in the middle, continue to arrange zero or even pairs of high-speed flat signal pairs 1 evenly and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com