Ventilation mechanism, healthcare shoe with ventilation mechanism, and manufacturing method of healthcare shoe

A technology for air chambers and shoe uppers, applied to shoe soles, shoe uppers, footwear, etc., can solve the problems of difficult installation of ventilation mechanism, complicated processing methods, and ugly appearance of shoe soles, etc., and achieve outstanding functions, simple structure, and convenient manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

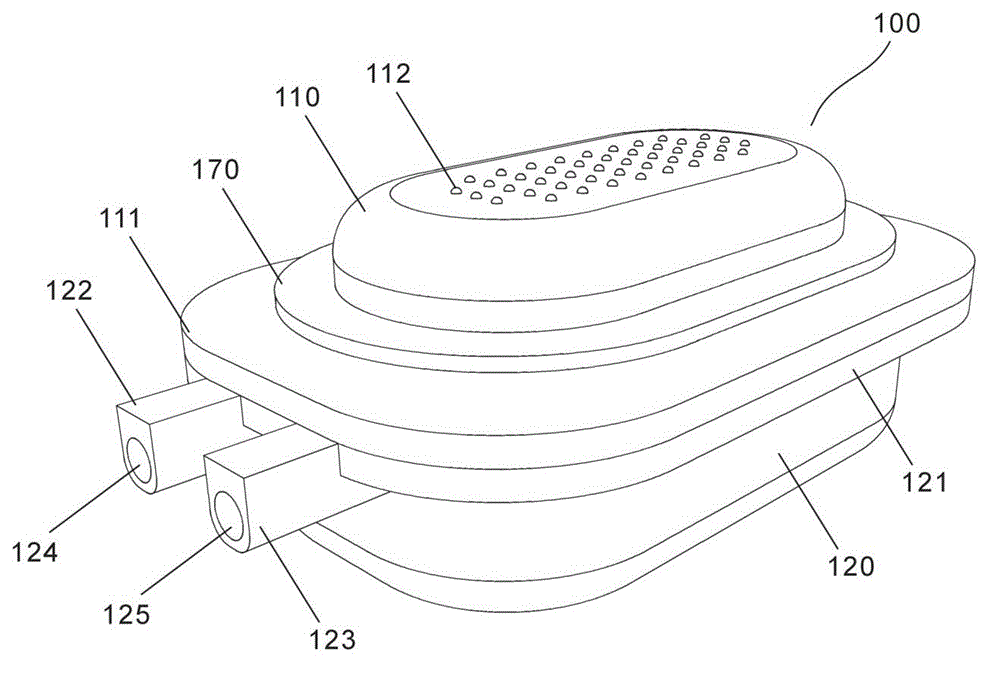

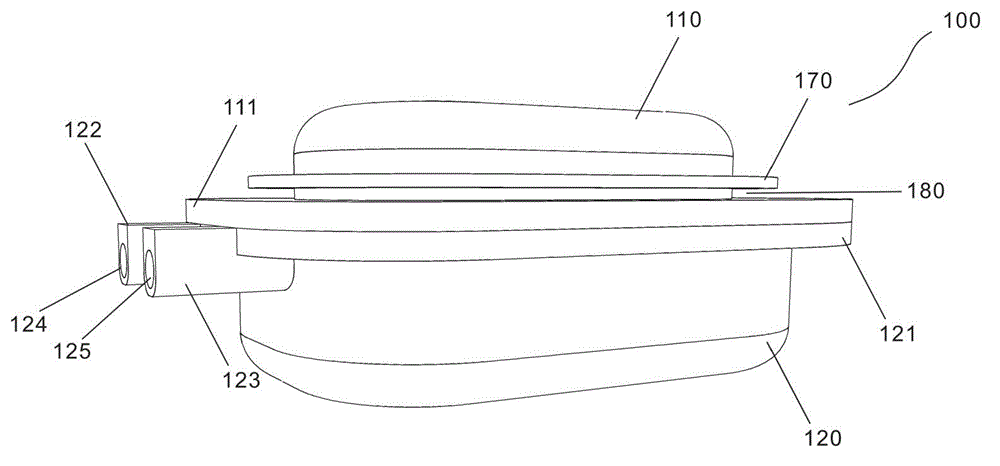

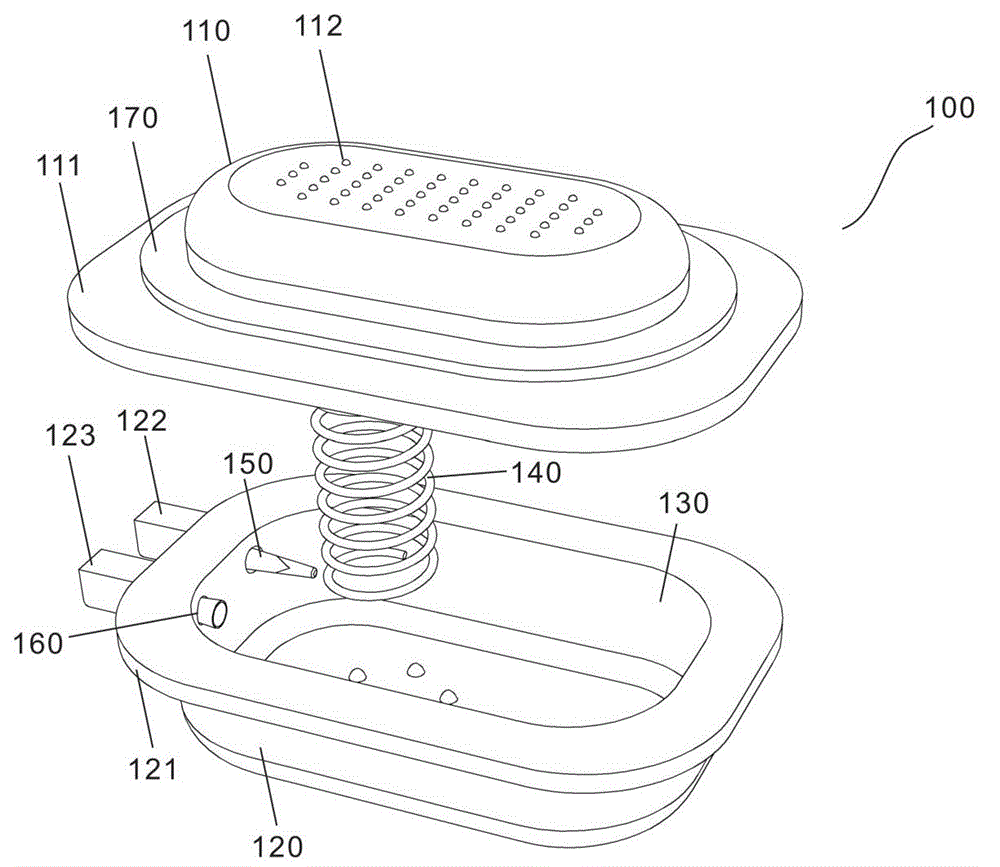

[0043] refer to Figure 1 to Figure 9 , this example provides figure 1 with figure 2 Shown is a ventilation mechanism 100, the ventilation mechanism 100 is placed in the sole, which includes: an upper casing 110, which has a first connecting portion 111, and is opened downward, and is made of elastic material; the lower casing 120, has a second connecting portion 121, and the opening is upward; wherein, the upper casing 110 and the lower casing 120 are connected by the first connecting portion 111 and the second connecting portion 121 to form an airtight space Cavity 130; the cavity 130 is fixed with an elastic member; the lower housing 120 is provided with an air inlet joint 122 and an air outlet joint 123, and the air inlet joint 122 with the air inlet 124 is connected to There is an intake check valve 150, and an exhaust check valve 160 is arranged in the exhaust hole 125 on the exhaust hole joint 123; an annular flange parallel to the first connecting part is arranged o...

no. 2 example

[0050] refer to Figure 10 According to the second embodiment of the present invention, a health-care shoe 200 with ventilation function is provided, which includes a shoe upper 210, an inner bottom 220 and an outer bottom 230, wherein, between the inner bottom 220 and the outer bottom 230, there is a In the above-mentioned ventilation mechanism 100, the heel of the outer sole 230 is provided with the cavity 231 of the lower shell 120 of the ventilation mechanism 100; The installation hole 221 matched with the groove 180, the front palm of the inner sole 220 is provided with a vent hole 222; a protruding air chamber 240 is provided under the vent hole 222; the outsole 230 is provided with an air chamber cavity 232 , the first air tube accommodating groove 233 and the second air guiding tube accommodating groove 234; the air chamber 240 communicates with the air inlet joint 122 through the first air guiding tube 250; the exhaust hole joint 123 passes through the second air guid...

no. 3 example

[0052] refer to Figure 11 According to the third embodiment of the present invention, a health-care shoe 200 with ventilation function is provided, which includes a shoe upper 210, an inner bottom 220 and an outer bottom 230, wherein: between the inner bottom 220 and the outer bottom 230, there is In the above-mentioned ventilation mechanism 100, the heel of the outer sole 230 is provided with the cavity 231 of the lower shell 120 of the ventilation mechanism 100; The installation hole 221 matched with the groove 180, the front palm of the inner sole is provided with a vent hole 222; a protruding air chamber 240 is provided under the vent hole 222; the outsole 230 is provided with an air chamber cavity 232 , the first air guide groove 280 and the second air guide groove 290; the air chamber 240 communicates with the air inlet joint 122 through the first air guide groove 280; the exhaust hole joint 123 communicates with the second air guide groove 290 Outsole air vent 270 Uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com