Vacuum absorption platform with two-dimension angle adjustment function

A technology of vacuum adsorption platform and two-dimensional angle, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of unstable placement, fragmentation and scrapping, and difficult placement, etc., to improve processing accuracy and measurement accuracy, avoid deformation, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

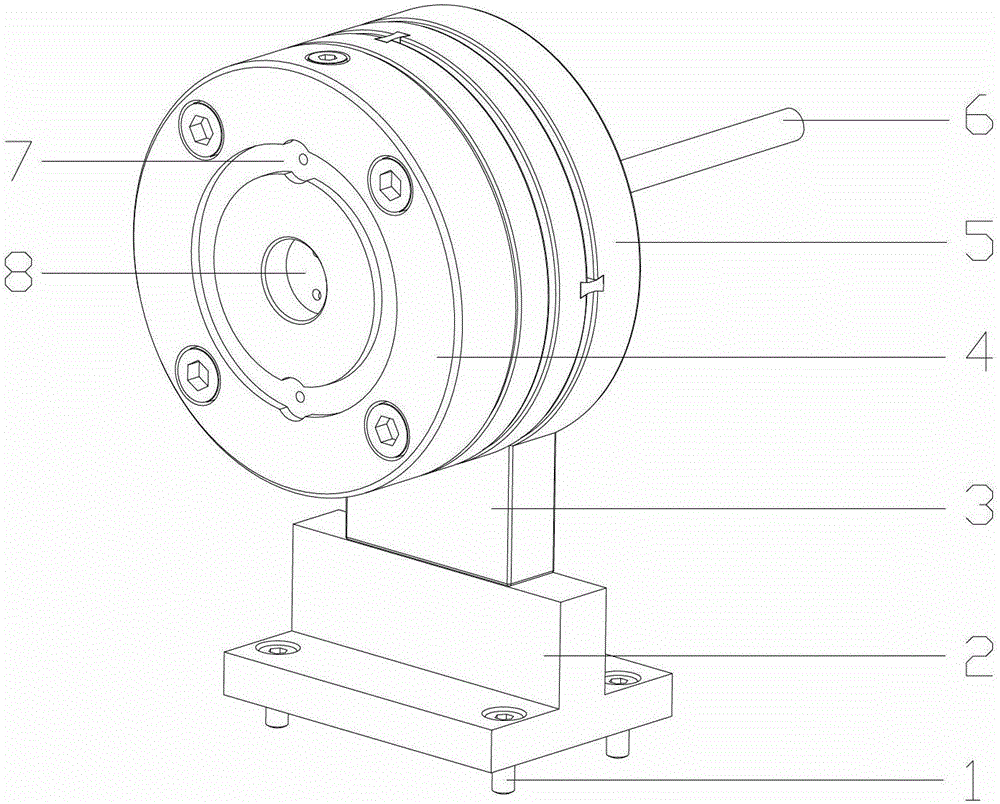

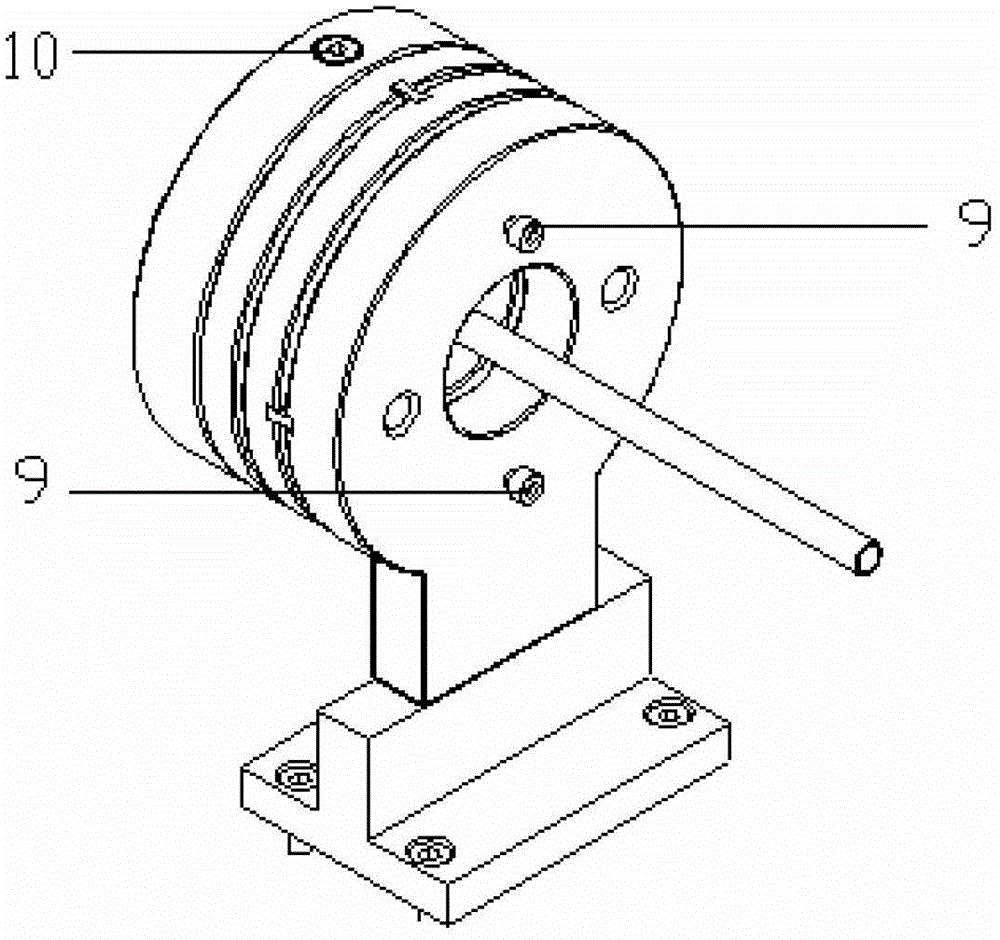

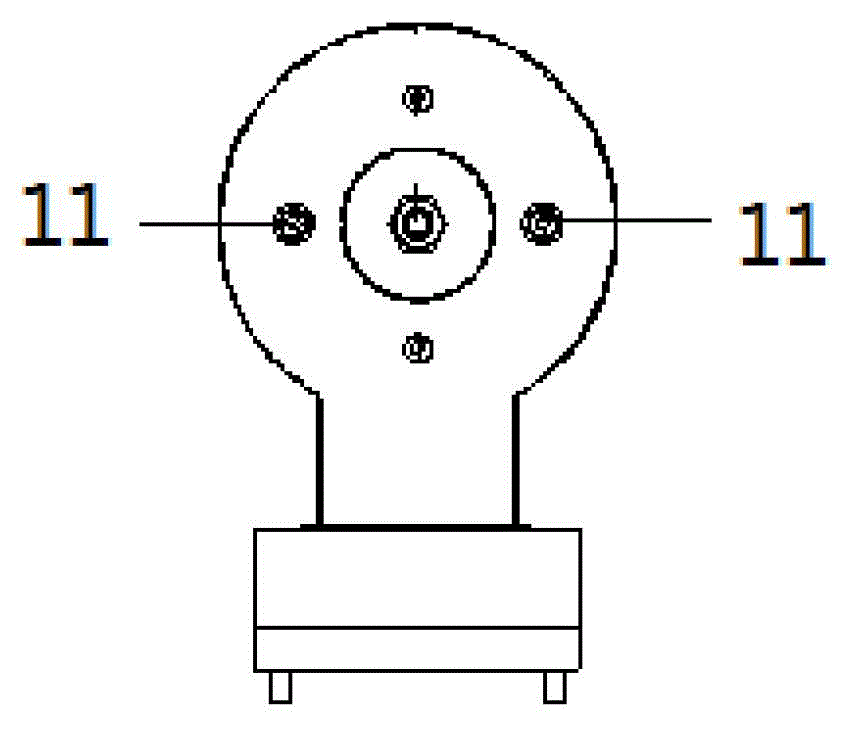

[0032] Such as Figure 1 to Figure 4 As shown, the technical solution of the present invention is: a vacuum adsorption platform with a two-dimensional angle adjustment function, including a base 2, a fixed base 3, a vacuum suction cup 4, a two-dimensional angle adjustment seat 5 and an exhaust pipe 6; The device is a vacuum pump;

[0033] Wherein, the base 2 is a two-stage structure of upper and lower;

[0034] An adsorption air chamber 8 is opened at the center of the vacuum chuck 4, and an adsorption air groove 7 is opened on the outer end surface of the vacuum chuck 4;

[0035] The two-dimensional angle adjustment seat 5 is composed of a first adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com