Method for purifying epoxy chloropropane

A technology of epichlorohydrin and side line, which is applied in the field of epichlorohydrin purification, which can solve the problems of high water content and light components of raw crude epichlorohydrin, low purity of epichlorohydrin, etc., and achieve energy consumption Decrease, reduce the effect of demanding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The finished tower adopts structured packing tower, filled with stainless steel corrugated packing (equivalent to 4 theoretical plates / m). The full column has 40 theoretical plates. A liquid phase sideline extraction outlet is set at the 12th theoretical plate downward from the reflux port on the top of the tower, and the tower feed port is located at the 25th theoretical plate.

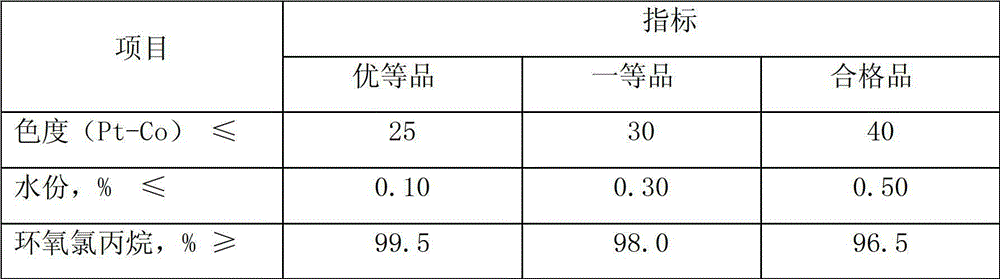

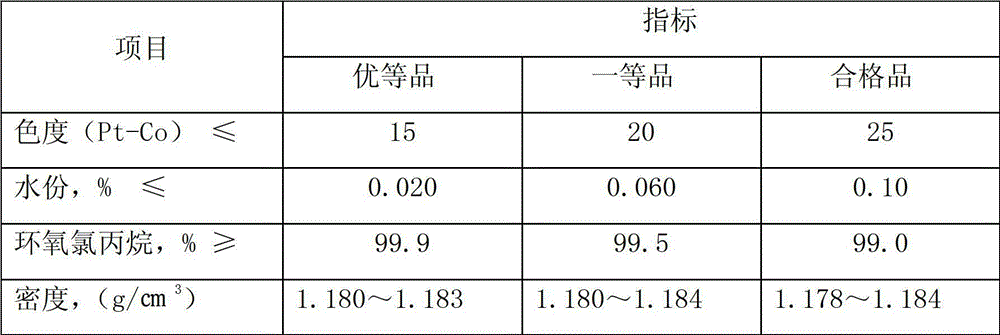

[0020] The finished product tower feed (from the dehydration tower kettle) is 1500kg / h, which contains 98.6% of epichlorohydrin, 0.1% of water, 0.01% of light components, and 1.29% of heavy components. The operating pressure at the top of the control tower is -56KPa (gauge pressure), the temperature is 90°C, and the reflux ratio is 3.5. The output at the top of the tower is 92.4kg / h, which contains 1.5% water, 0.16% light components, and 98.35% epichlorohydrin, which is sent to the top of the dehydration tower. The finished epichlorohydrin produced from the side line liquid phase is 1380kg / h...

Embodiment 2

[0023] The finished tower adopts the guided valve tower, and there are 55 guided valve trays in the whole tower (equivalent to 25 theoretical plates). From the top reflux port to the bottom of the 20th plate (equivalent to the 9th theoretical plate) there is a liquid phase side line extraction outlet, and the 45th plate (equivalent to the 20th theoretical plate) is the tower feed port.

[0024] The finished product tower feed (from the dehydration tower kettle) is 1500kg / h, which contains 98.6% of epichlorohydrin, 0.1% of water, 0.01% of light components, and 1.29% of heavy components. The operating pressure at the top of the control tower is -91KPa (gauge pressure), the temperature is 50°C, and the reflux ratio is 3.0. The output at the top of the tower is 124.2 kg / h, of which 1.127% water, 0.121% light components and 98.753% epichlorohydrin are sent to the top of the dehydration tower. The finished epichlorohydrin produced from the side line liquid phase is 1350kg / h, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com