Precast pressed-in underground continuous wall and construction method thereof

A technology of underground diaphragm wall and construction method, which is applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of uneconomical cost accounting, adverse environmental impact, and large engineering volume, and achieve simplified construction technology and low excavation volume. The effect of reducing and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

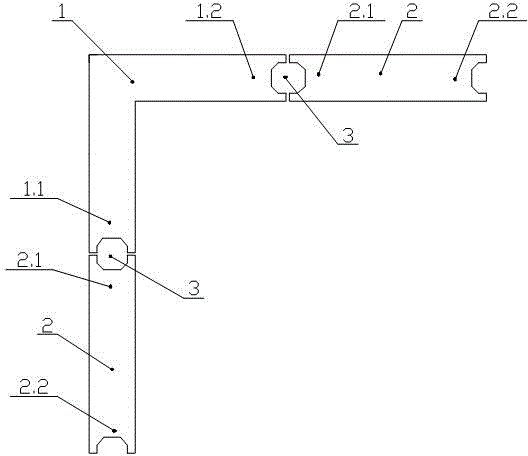

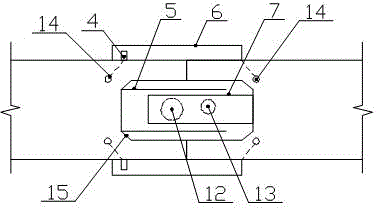

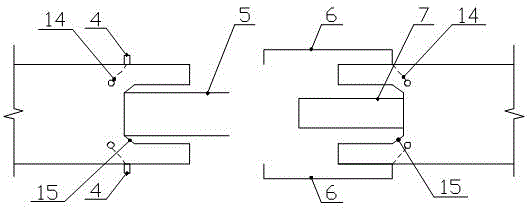

[0032] Such as figure 1 , 2 As shown in and 3, a prefabricated press-in type underground continuous wall, the continuous wall is formed by splicing prefabricated corner walls 1 and straight walls 2; the corner walls 1 and straight walls 2 are prefabricated by reinforced concrete , the two ends of the corner wall body 1 are the first connecting portion 1.1 and the second connecting portion 1.2 respectively, the two ends of the straight wall body 2 are the third connecting portion 2.1 and the fourth connecting portion 2.2, the The first, second, third, and fourth connecting parts are front-end connecting parts or rear-end connecting parts; when docking, the front-end connecting parts dock with the adjacent rear-end connecting parts, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com