Elastic buffer

An elastic buffering and buffering technology, applied in the field of rubber buffers, can solve the problems of complex elastic buffer structure, poor stop elastic performance, single function, etc., and achieve the effect of simple and reasonable structure, good buffering effect, and optimized structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

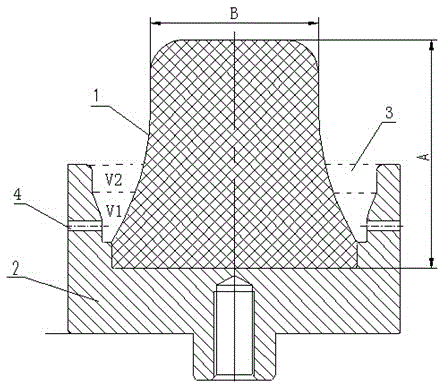

[0033] like figure 1As shown, a multi-functional elastic buffer includes a rubber body 1 and a metal base 2, the rubber body 1 is a conical structure, the ratio of its height A to the top diameter B is 1.0, and the bottom diameter C to the top diameter B The ratio range is 1.3, the top surface of the metal base 3 is provided with a rounded table-shaped counterbore 3, the bottom surface of the rubber body 1 is vulcanized at the bottom of the counterbore 3, the gap between the counterbore 3 and the rubber body 1 A space gap with a V-shaped axial section is formed between them, and the bottom end of the metal base 3 is connected to the steel spring system; the V-shaped space gap is organized by two parts, one is the V-shaped bottom space gap V1, and the volume ratio of VI and V2 is according to The rigidity requirement of the vehicle bogie for the buffer is designed to be 2:1. The side formed by the metal base in V1 is designed to be in the shape of a conical surface connected to...

Embodiment 2

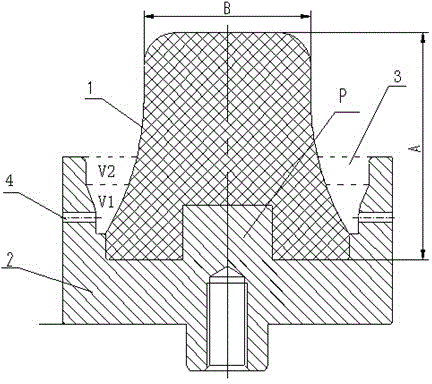

[0035] A multifunctional elastic buffer, including a rubber body 1 and a metal base 2, the rubber body 1 is a conical structure, the ratio of its height A to the top diameter B is 1.6, and the ratio range of the top diameter B to the bottom diameter is 1.5 , the top surface of the metal base 3 is provided with a rounded table-shaped counterbore 3, the bottom surface of the rubber body 1 is vulcanized on the bottom of the counterbore 3, and a shaft is formed between the counterbore 3 and the rubber body 1. A V-shaped space gap is formed in the cross-section, and the bottom end of the metal base 3 is connected to the steel spring system; the V-shaped space gap is organized by two parts, one is the V-shaped bottom space gap V1, and the other is the V-shaped upper opening space gap V2, The volume ratio of VI and V2 is designed to be 3:1 according to the rigidity requirements of the vehicle bogie for the buffer. The side of V1 formed by the metal base is designed to be a conical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com