Centering debug method of multiple racks and trays of engine test stand

A debugging method and engine support technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of cumbersome adjustment process, impact on equipment utilization, and large workload, so as to avoid repeated adjustment, Improve test efficiency and provide the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

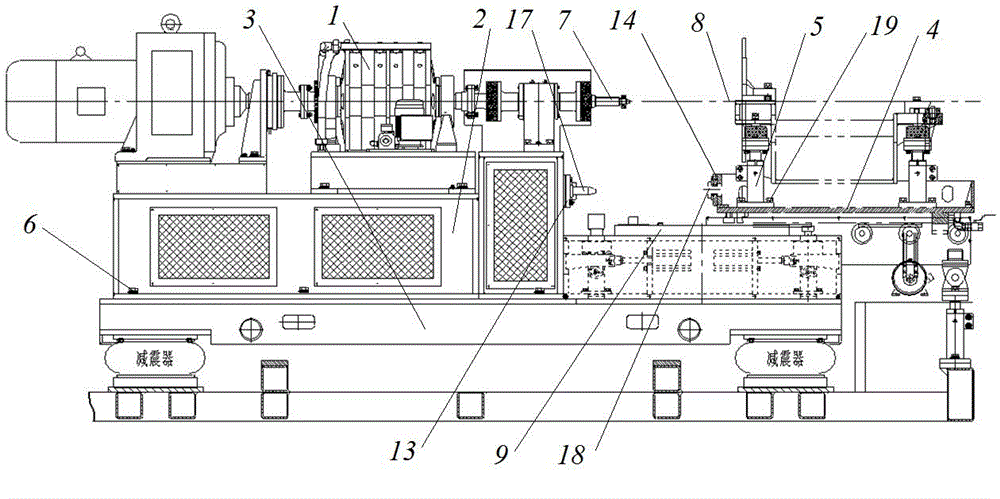

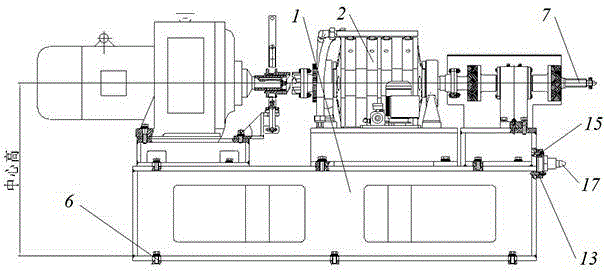

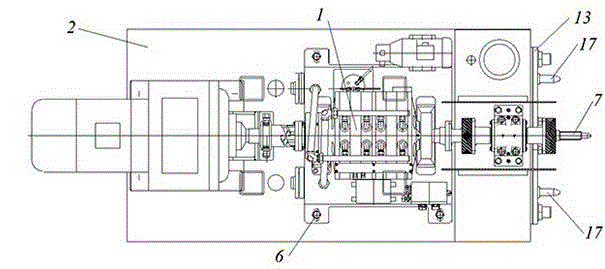

[0041] An embodiment of the present invention is figure 1 ~As shown in the figure: The engine test bench includes a bench 2 for installing the test system 1, a base 3 for installing the bench 2, and a tray 4 provided with an engine bracket 5 for installing the engine. The bench 2 passes through The bench tightening screw 6 is assembled on the front side of the base 3 of the test bench; the power input shaft of the test system 1, that is, the main shaft of the bench 2 is set towards the rear side of the bench 2, and the height of the bench main shaft 7 from the surface of the base 3 is defined as The center of the test system 1 is high. The platform 2 and the tray 4 are guided and moved through the matching male and female guide rails 10. The base 3 is provided with a male guide rail fastening screw 11 for fastening the male head guide rail 9. The tray 4 There is a female guide rail fastening screw 12 for fastening the female head guide rail 10; between the stand 2 and the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com