High-temperature rigidity measuring method based on electrified heating

A measurement method and hardness technology, applied in the direction of testing the hardness of materials, etc., can solve the problems such as the inability to easily and quickly measure the hardness of metals, the complexity of the hardness measurement equipment, the large size of the measurement equipment, etc., to achieve low equipment and process costs, and improved efficiency. Simple effect of heating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

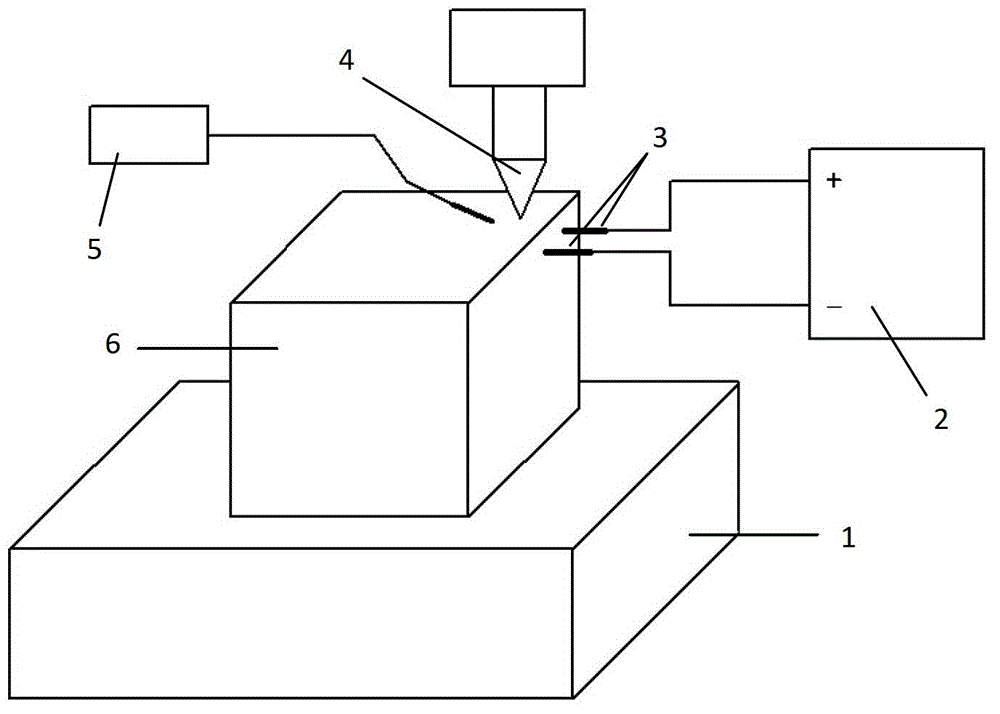

[0028] see figure 1 , the high-temperature hardness measurement method based on electric heating described in the embodiment of the present invention, comprises the following steps:

[0029] 1) Prepare hardness tester (hardness tester includes hardness tester platform 1, hardness tester indenter 4, etc.), adjustable DC power supply 2, 2 heating electrodes 3, temperature sensor (thermocouple) 5 and the metal workpiece to be tested 6. The temperature sensor 5 can also be an infrared thermometer; the indenter of the hardness tester can be a diamond indenter or a sapphire indenter. When the measured temperature is not greater than 800°C, a diamond indenter is selected. When the measured temperature is greater than 800°C , When the temperature is less than 1300℃, select the sapphire indenter. The working parameters of the adjustable DC stabilized power supply are that the voltage is not greater than 5V, and the current is not greater than 400A.

[0030] 2) Put the metal workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com