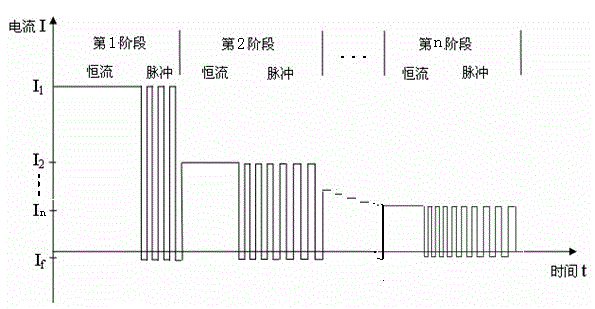

Grading constant current charging method with voltage-controlled pulse

A technology of constant current charging and pulse charging and discharging, which is applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., and can solve the problems of long charging process time and charging power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

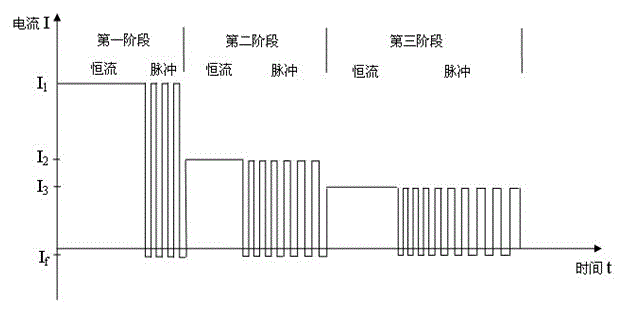

[0019] as attached figure 1 As shown, the charging is divided into three stages, and each stage is divided into two processes of constant current charging and pulse charging and discharging: the first stage constant current charging current I 1 The value is set according to the rated current of the battery electrode terminal and its connecting cable, the constant current charging current I of the second and third stages 2 , I 3 I 1 1 / 2 and 1 / 3 of 1 / 2 and 1 / 3; the charging current value of each stage charge and discharge pulse process is the same as the current value of constant current charging at this stage, that is, I 1 , I 2 and I 3 ; The discharge current of each stage charge and discharge pulse process uniformly adopts the same small current in each stage, and the value I f = 0.006I 1 .

[0020] The charging process control method of the above three stages: the first stage constant current I 1 The charging process continues until the battery voltage rises to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com