Electric construction machine

A construction machinery and electric technology, applied in electric power units, motor vehicles, power units, etc., can solve the problems of reduced work efficiency and narrow installation location of battery devices, and achieve the effects of improved work efficiency, easy maintenance, and easy exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

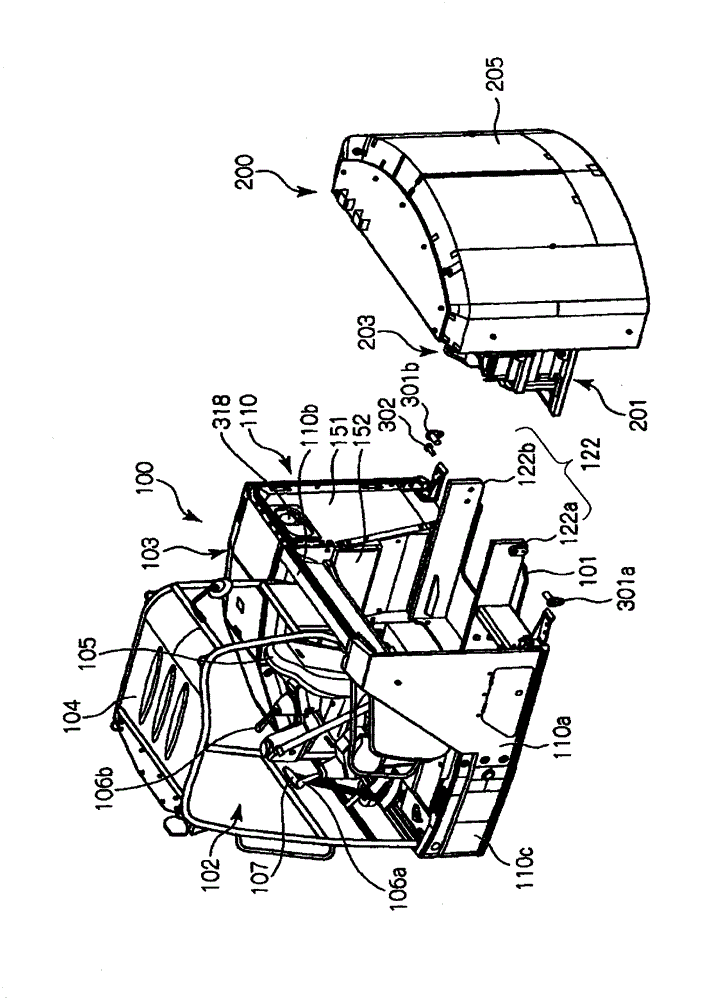

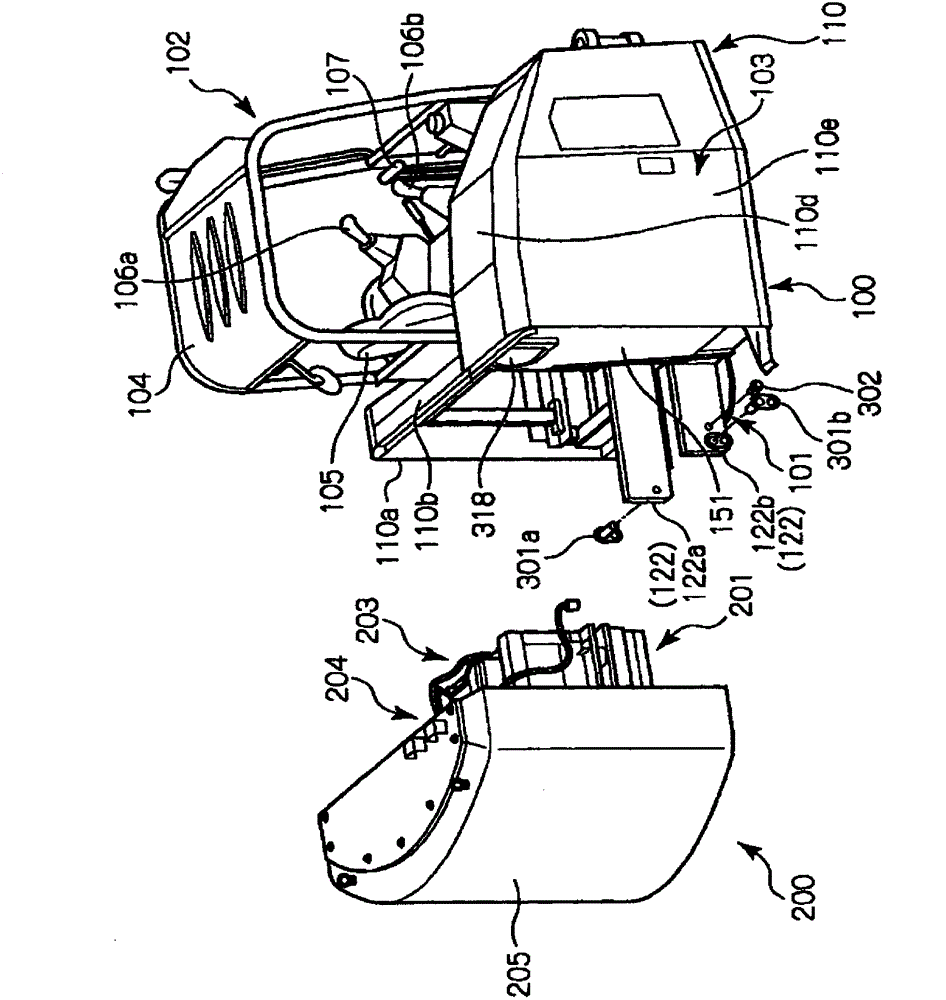

[0072] Hereinafter, an embodiment of an electric construction machine according to the present invention will be described in detail with reference to the drawings, taking an example in which the present invention is applied to a hydraulic excavator.

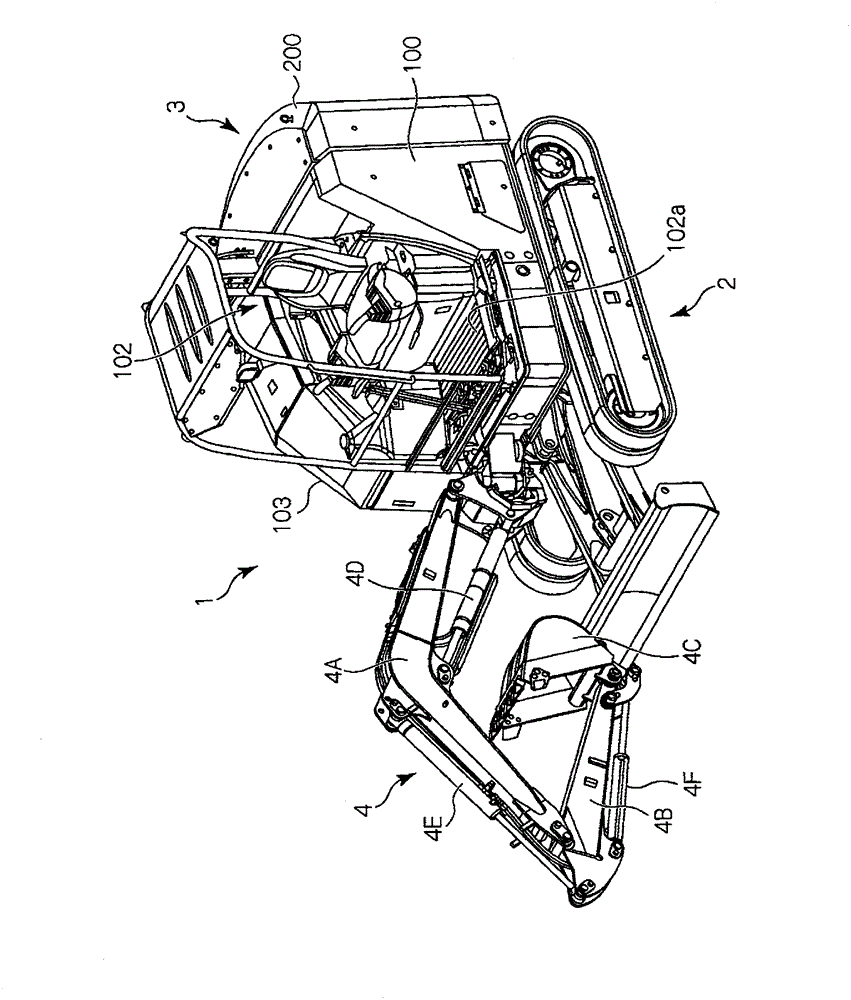

[0073] figure 1 It is a perspective view showing the appearance of the electric hydraulic excavator in this embodiment.

[0074] figure 1 Among them, reference numeral 1 is an electric hydraulic excavator. This hydraulic excavator 1 has: a crawler-type undercarriage 2 capable of self-propelled; Rotating body 3 ; a swing-type working device 4 mounted on the front side of the upper rotating body 3 for excavating sand and soil. The working device 4 is composed of a boom 4A, an arm 4B, a bucket 4C, a boom cylinder 4D, an arm cylinder 4E, a bucket cylinder 4F, and the like.

[0075] Figure 24 It is a figure which shows the drive and cooling system which the hydraulic excavator 1 has.

[0076] The hydraulic excavator 1 has: a hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com