Method for preparing invert sugar and electrolytes injection

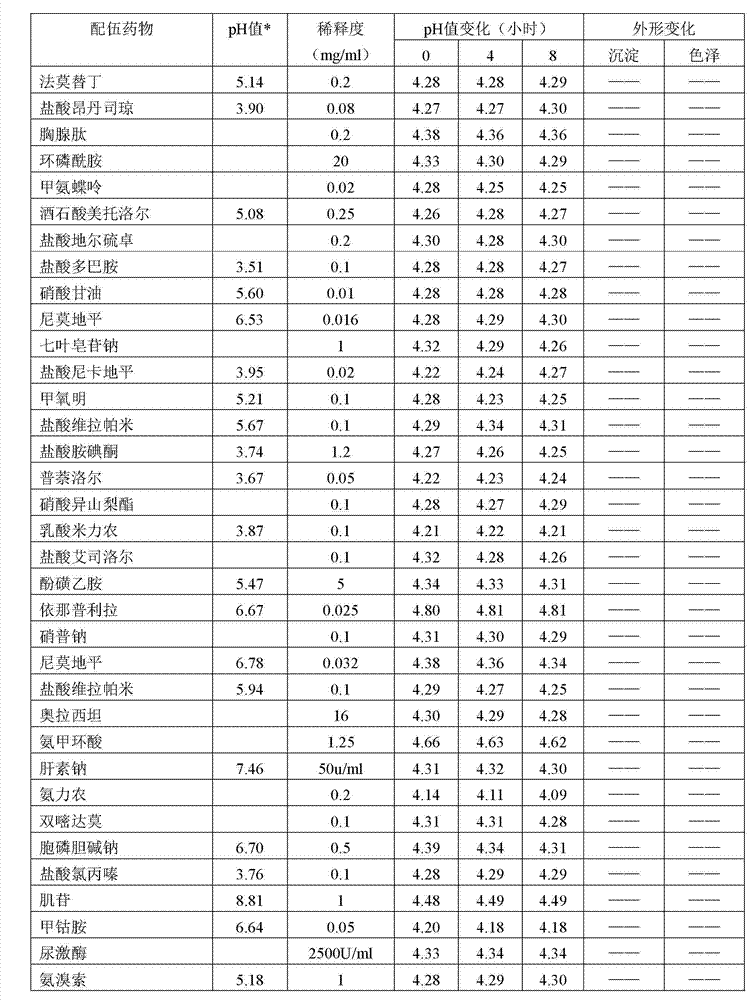

A technology for electrolyte injection and invert sugar, applied in the field of medicine, can solve the problems of data and publication without pH adjustment, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

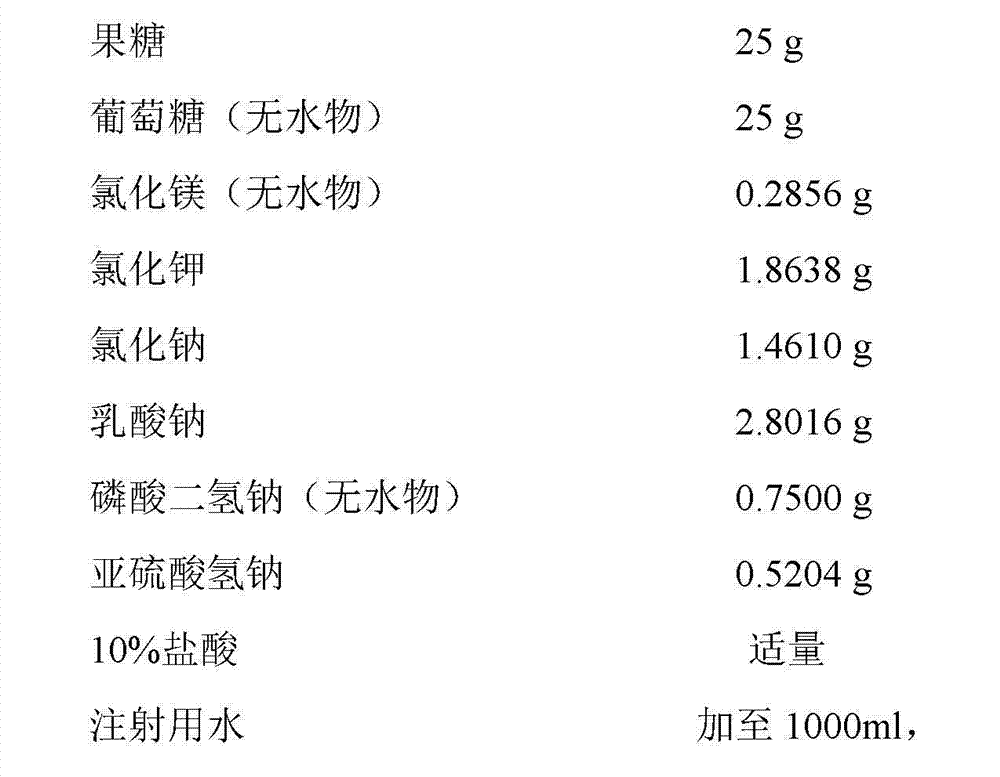

[0023] Add an appropriate amount of water for injection into the concentrated preparation tank, put in the prescribed amount of glucose, fructose, magnesium chloride, potassium chloride, sodium chloride, sodium lactate, sodium dihydrogen phosphate, and sodium bisulfite, and stir until completely dissolved.

[0024] Add 0.05% (w / v) activated carbon for needles that has been moistened and boiled into the concentrated preparation tank, and after stirring for 15 minutes, turn on the concentrated preparation's own circulation system to decarbonize for 15-20 minutes, and pump the liquid medicine into the thin preparation tank. After the delivery, add water for injection into the concentrated preparation tank, cycle and wash it three times, and pump the cleaning water into the thin preparation tank.

[0025] Add water for injection to the required preparation amount in the dilute preparation tank, stir for 15-20 minutes, initially measure the pH value of the liquid, adjust the pH valu...

Embodiment 2

[0028] Add an appropriate amount of water for injection into the concentrated preparation tank, put in the prescribed amount of glucose, fructose, magnesium chloride, potassium chloride, sodium chloride, sodium lactate, sodium dihydrogen phosphate, and sodium bisulfite, and stir until completely dissolved.

[0029] Add 0.05% (w / v) activated carbon for needles that has been moistened and boiled into the concentrated preparation tank, and after stirring for 15 minutes, turn on the concentrated preparation's own circulation system to decarbonize for 15-20 minutes, and pump the liquid medicine into the thin preparation tank. After the delivery, add water for injection into the concentrated preparation tank, cycle and wash it three times, and pump the cleaning water into the thin preparation tank.

[0030] Add water for injection to the required preparation amount in the dilute preparation tank, stir for 15-20 minutes, initially measure the pH value of the liquid, adjust the pH valu...

Embodiment 3

[0033] Add an appropriate amount of water for injection into the concentrated preparation tank, put in the prescribed amount of glucose, fructose, magnesium chloride, potassium chloride, sodium chloride, sodium lactate, sodium dihydrogen phosphate, and sodium bisulfite, and stir until completely dissolved.

[0034] Add 0.08% (w / v) activated carbon for needles that has been moistened and boiled into the concentrated preparation tank, and after stirring for 15 minutes, turn on the concentrated preparation's own circulation system to decarbonize for 15-20 minutes, and pump the liquid medicine into the thin preparation tank. After the delivery, add water for injection into the concentrated preparation tank, cycle and wash it three times, and pump the cleaning water into the thin preparation tank.

[0035] Add water for injection to the required preparation amount in the dilute preparation tank, stir for 15-20 minutes, initially measure the pH value of the liquid, adjust the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com