Filter core for down flow type filter cylinder dust remover

A filter cartridge dust collector and submerged flow technology, applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of difficulty in removing dust and increase the difficulty of cleaning, so as to improve filtration efficiency and prolong cleaning. Ash cycle and filter life, the effect of increasing the filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

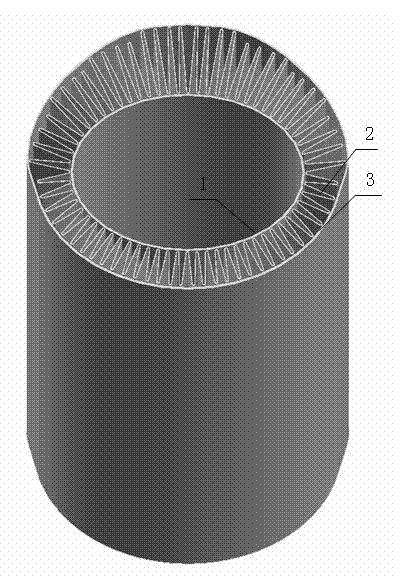

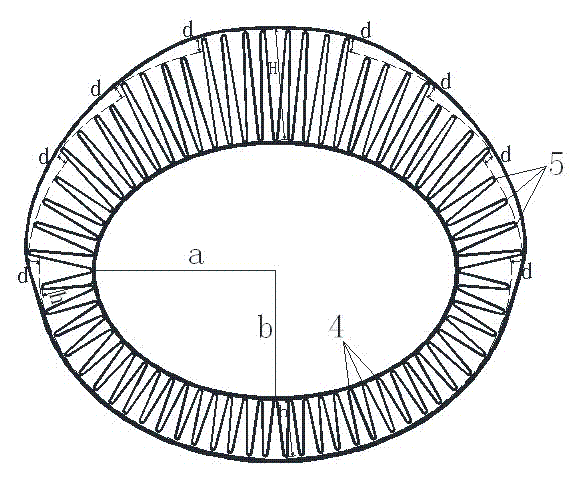

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. The present invention is an elliptical cylindrical filter element with a filter cloth outer covering and pleat heights distributed in steps for a downflow filter cartridge dust collector, including an elliptical porous core 1, a pleat-shaped Filter layer 2 and coarse filter cloth 3. The rough filter cloth 3 covers the outer surface of the pleated filter layer 2 . The pleated filter layer 2 is placed between the elliptical cylindrical filter element 1 and the coarse-effect filter cloth 3. The pleated filter layer 2 is a cylindrical structure and is folded into pleats by a certain length of filter material. The pleats of each pleat The inner edges are all distributed on the outer circumference of the elliptical porous core 1, and the pleat height distribution is symmetrical about the minor axis of the ellipse. The pleat heights on one side corresponding to the semi-major...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com