Perforated pipe burr removing machine

A technology of deburring machine and perforated tube, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. Strength, the effect of avoiding the phenomenon of knife jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but it is not intended to limit the present invention.

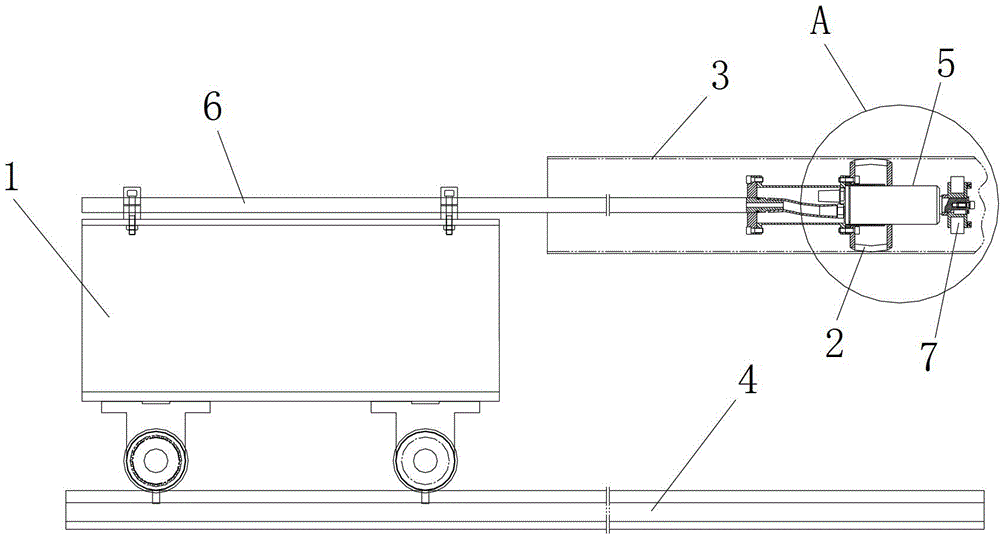

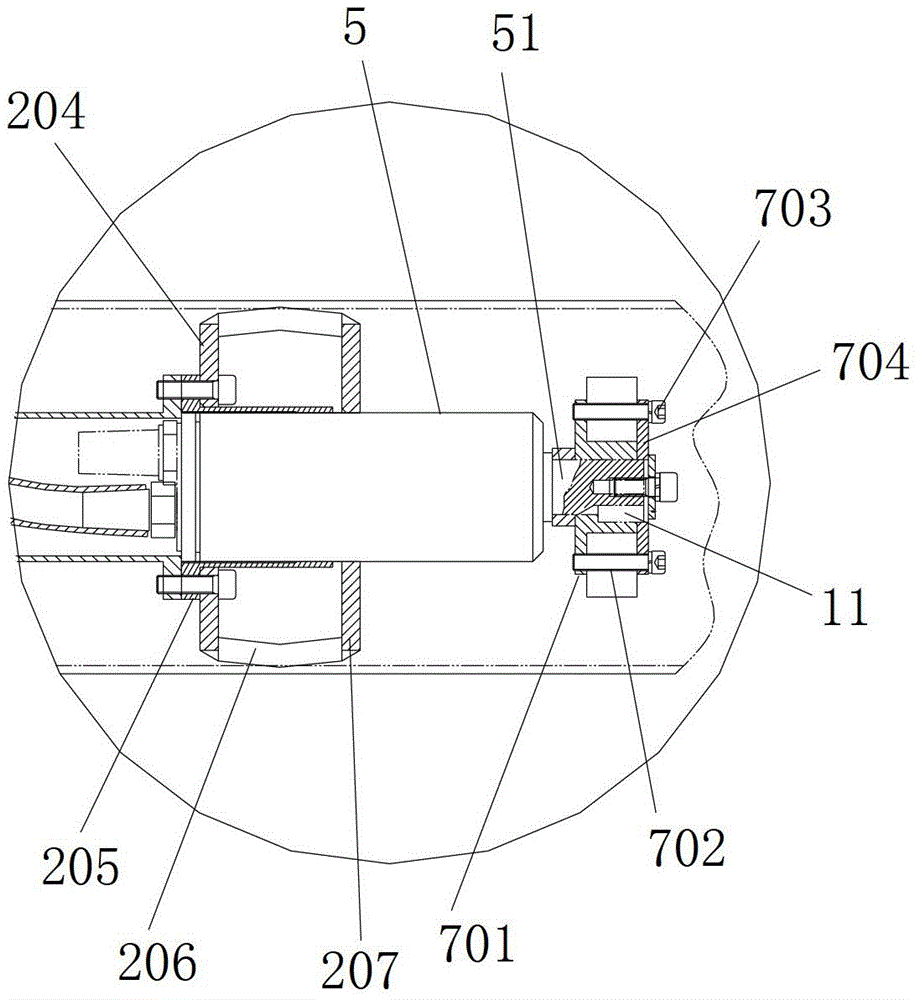

[0028] figure 1 It is a schematic diagram of the structure of the perforated tube deburring machine of the present invention; figure 2 for figure 1 Enlarged view of part A of. Such as figure 1 with figure 2 As shown, the perforated tube deburring machine includes a rail car 1 that moves linearly along a rail 4, and a support arm 6 parallel to the rail 4 is fixed on the rail car 1. A rotation driving device 5 is connected to the front end of the support arm 6. A cutter 7 is fixed to the rotary drive shaft 51 of the rotary drive device 5.

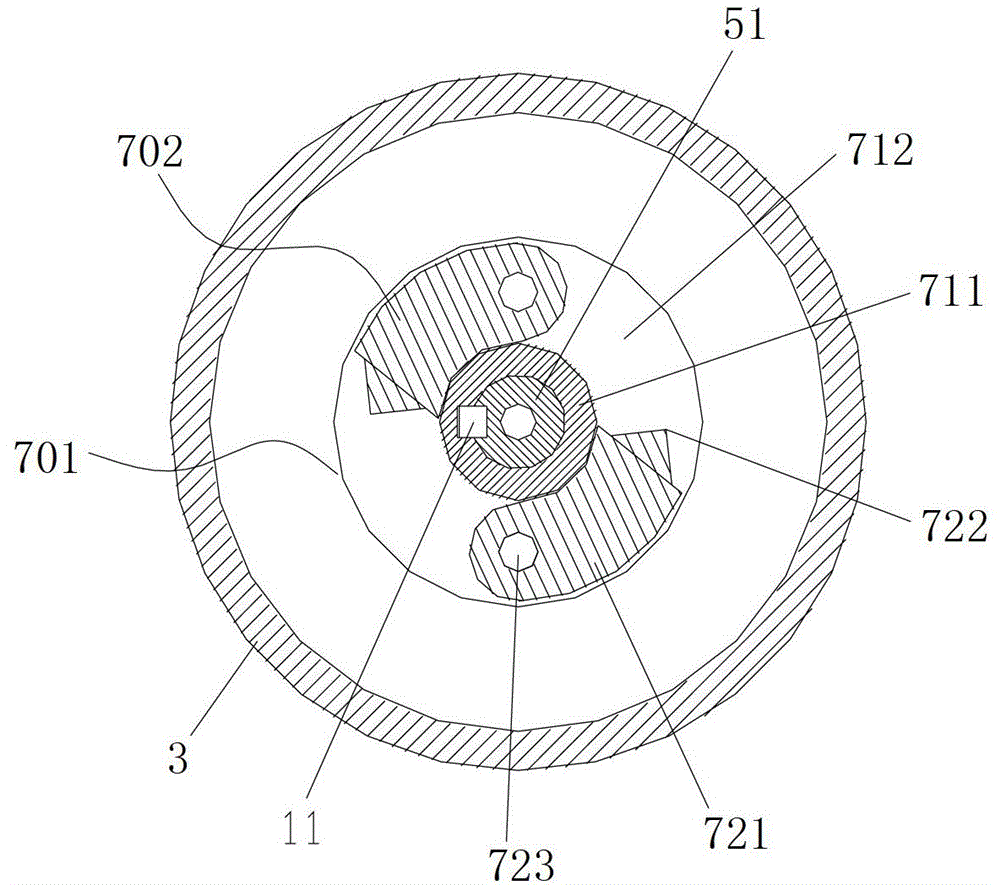

[0029] image 3 It is a schematic cross-sectional view of the cutter part of the perforated tube deburring machine of the present invention. Combine figure 1 , figure 2 with image 3 The tool 7 includes a tool holder 701 fixed to the rotating drive shaft and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com