Middle mold locking device

A locking device and tightening technology, which is applied in the direction of making medicines into special physical or taking forms, presses, manufacturing tools, etc. Problems such as misalignment with the middle die hole, hanging punch, etc., to achieve the effect of easy machining accuracy, easy removal of the clamping rod, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

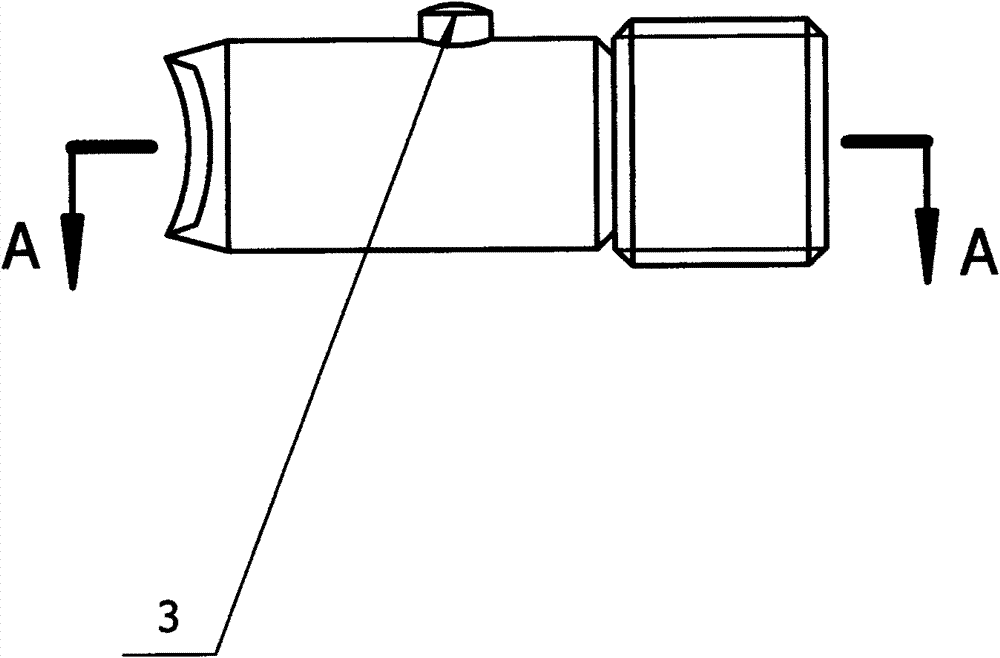

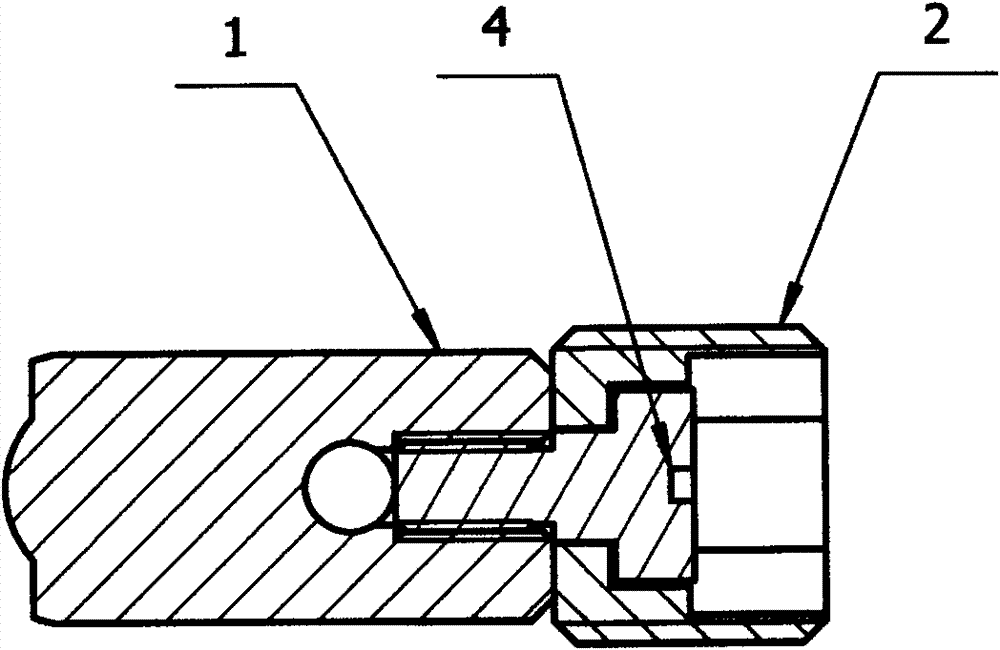

[0011] Such as figure 1 , figure 2 As shown, the middle mold locking device includes a tightening rod 1, an outer screw 2, a guide key 3 and a connecting screw 4, wherein the head structure of the fixing rod 1 is made into a circular convex arc, and the outer screw 2 connects with the connecting screw 4. The tightening rod 1 is connected and fixed, and the guide key 3 is fixed on the tightening rod 1

[0012] When the middle mold locking device made according to the above structure is working, the locking device is put into the middle mold screw hole on the turntable, and the guide key 3 on the tightening rod 1 is embedded in the keyway in the middle mold screw hole, and rotates The outer screw 2 pushes the tightening rod 1 into the annular groove of the middle mold gradually and horizontally along the guide key 3, so that the annular convex arc at the front end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com