Axial battery wheel that can be quickly disassembled by hand

A free-hand speed, axial technology, applied in the direction of wheels, wheel-axle combinations, power units, etc., can solve the problems of occupying practical space, damage and theft, etc., to reduce the center of gravity of the whole vehicle, reduce the weight of the whole vehicle, and prevent battery damage and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

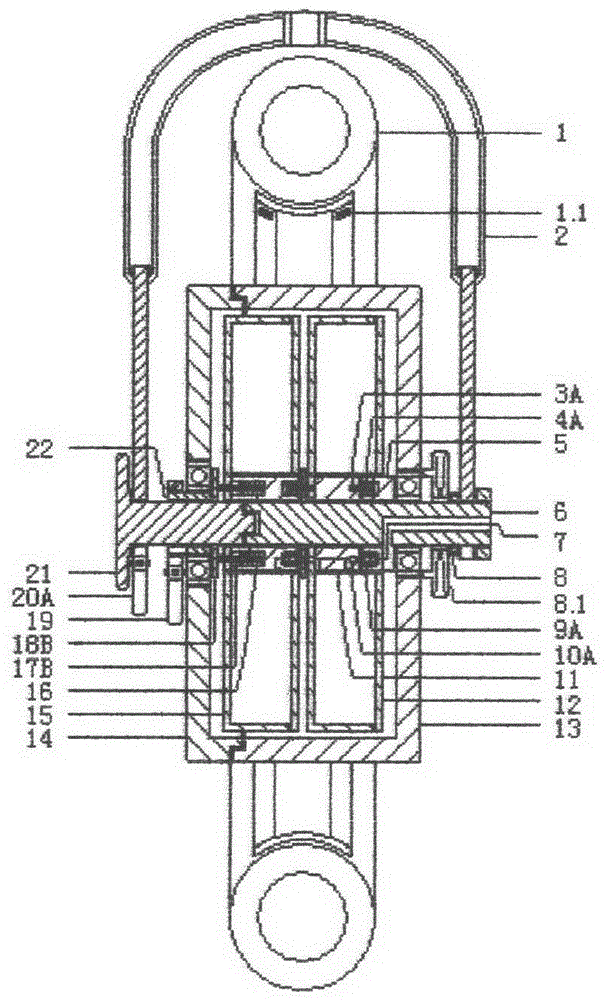

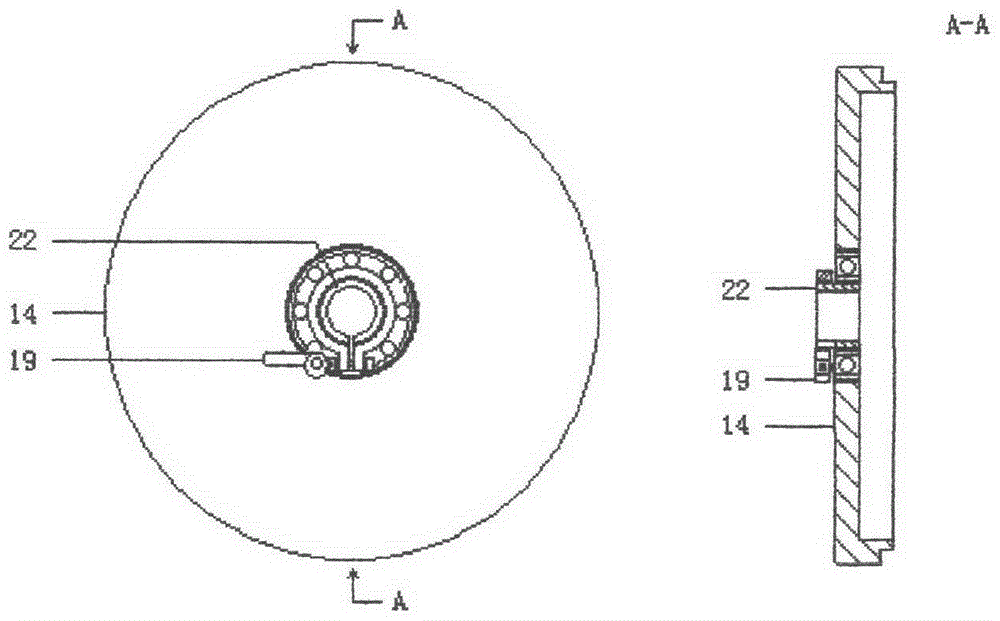

[0007] Embodiment one: if figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 8 , Figure 9 shown. The shaft section from the right end of the wheel right shaft 6 to the middle right has an axial through hole and a lower radial groove, and the groove communicates with the end section of the axial through hole, and the shaft section at the left end has an axial coupling hole. The left end of the wheel is the handle, and the shaft section at the right end is a small-diameter section whose diameter and length are equal to the shaft-connecting hole. The small-diameter section is placed in the shaft-connecting hole, and the middle section of the wheel shaft formed by connecting the right wheel shaft 6 and the left wheel shaft 21 is set in the middle-hole battery pack Inside, the shaft section on the right side of the battery pack is fixedly sleeved in the inner ring hole of the bearing of the hub disc 13, the shaft section on the left side is loosely fitted on t...

Embodiment 2

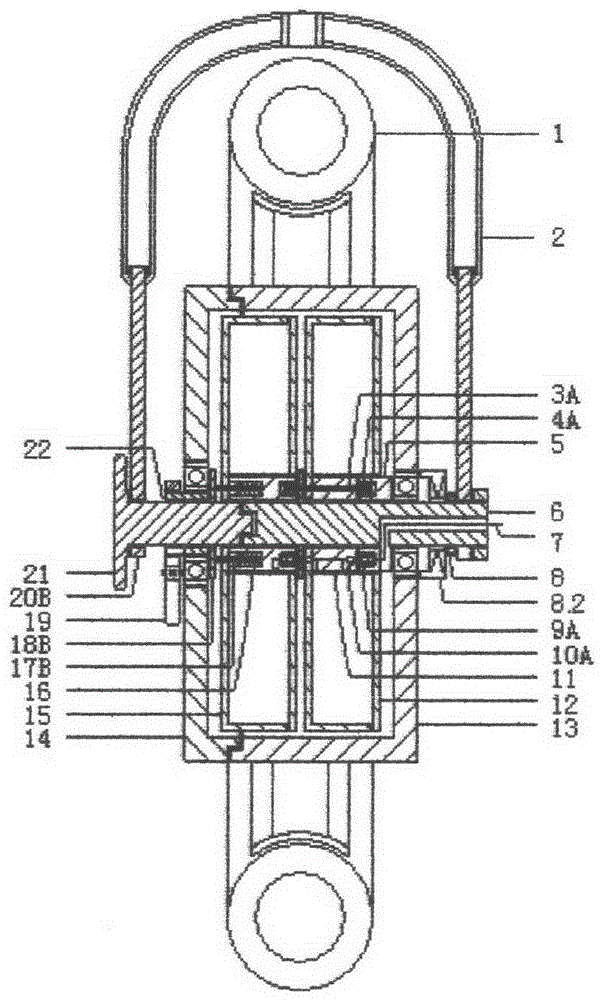

[0008] Embodiment two: if figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 , Figure 9 shown. The shaft section on the left side of sleeve shaft seam tube 22 is screwed into the screw port of the left fork 20B, and the shaft section between the bearing of hub disk 13 and sleeve shaft tube 8 is installed with brake drum 5.2, and the others are the same as in the first embodiment . Unscrew the quick release by hand, turn the left axle of the wheel to the left, and then the hubcap and battery can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com