Sleeper type electrohydraulic switcher

A switch machine and electro-hydraulic technology, applied to hydraulic equipment for manipulating turnouts or line breakers, railway car body parts, railway signals, etc., can solve the problem of rusting of switch machine parts, large locking force , many fault points, etc., to achieve high sealing protection level, improve impact resistance, and express accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

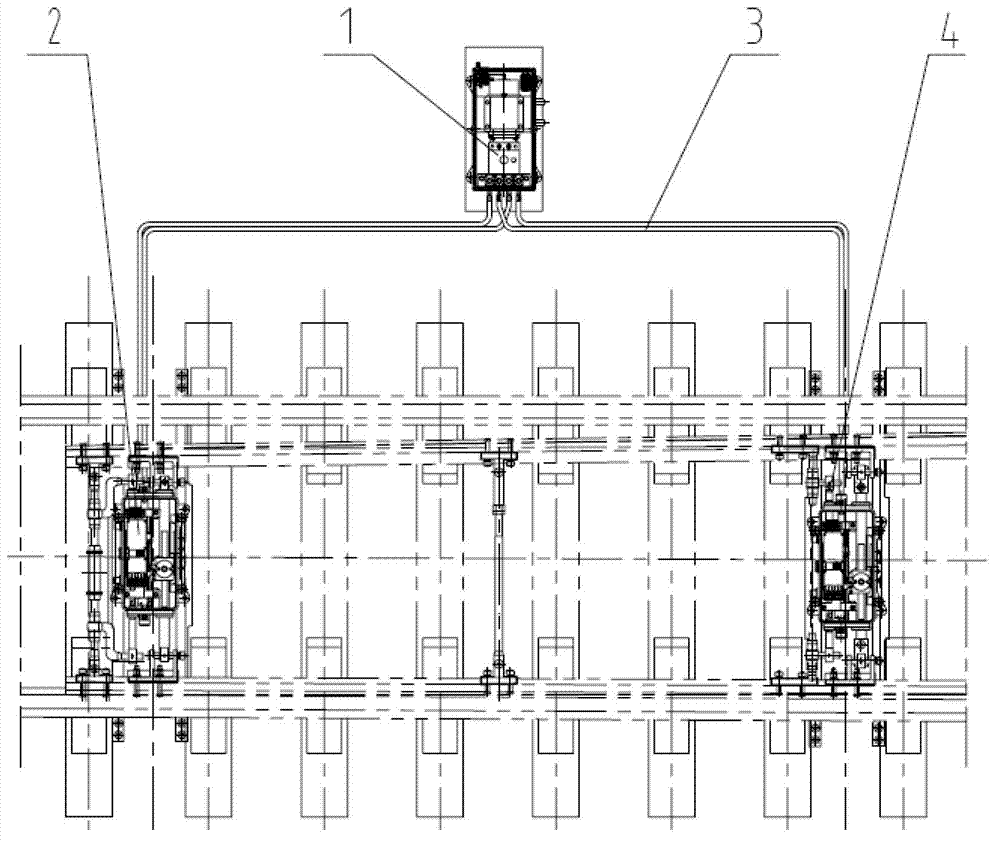

[0037] attached figure 1 Shown is a switch conversion schematic diagram of a sleeper electro-hydraulic switch machine with one hydraulic power unit driving two locking units. The hydraulic power unit 1 is installed next to the track, and the locking unit 2 is installed between the two basic rails of the turnout. A locking unit 2 is installed at each of the two traction points of the turnout. The hydraulic power unit 1 and the locking unit 2 pass through the oil pipe 3 connect.

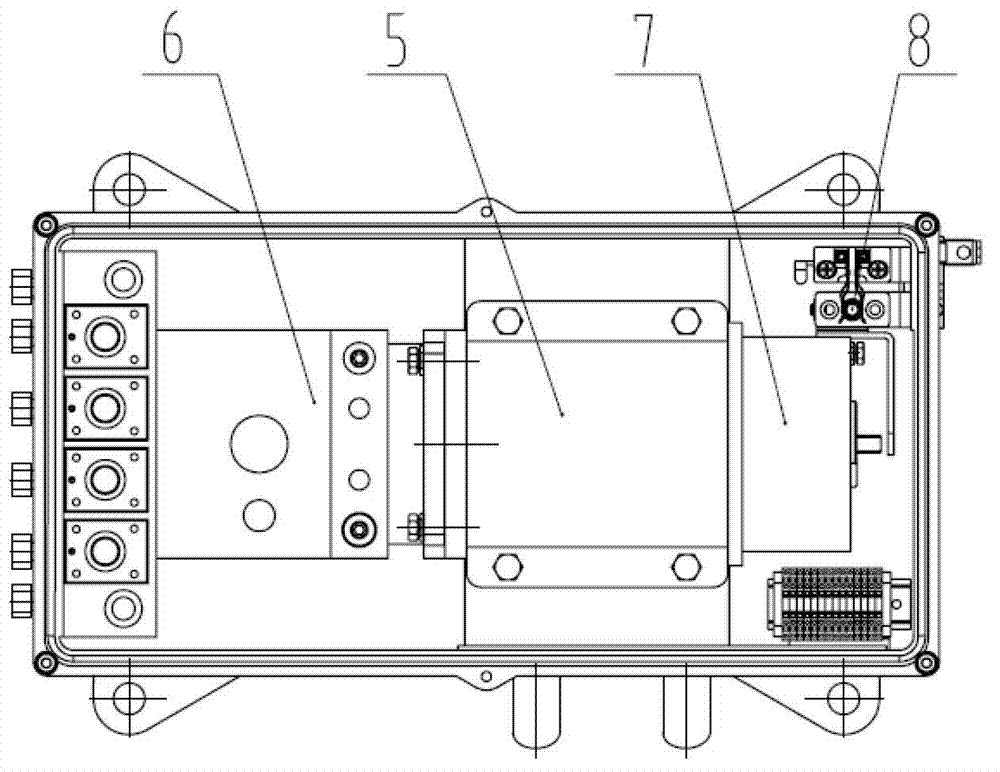

[0038] attached figure 2 Shown is the overall structure of the hydraulic power unit 1 , the hydraulic power unit includes a motor 5 , a pump valve group 6 a manual transmission mechanism 7 and a safety switch 8 . Turn off the safety switch 8, and manually drive the oil pump 6-1 to rotate through the transmission mechanism 7, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com