Method for reducing rudder resistance of ships

A technology of rudders and ships, which is applied in ship construction, rudder steering, hull and other directions to achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following provides preferred embodiments aiming at the above-mentioned technical features of the present invention. However, there are many types of ship rudders, and the shapes and structures are not exactly the same, so only the preferred embodiments are used for illustration, but the technical means used are the same, and will not be repeated one by one.

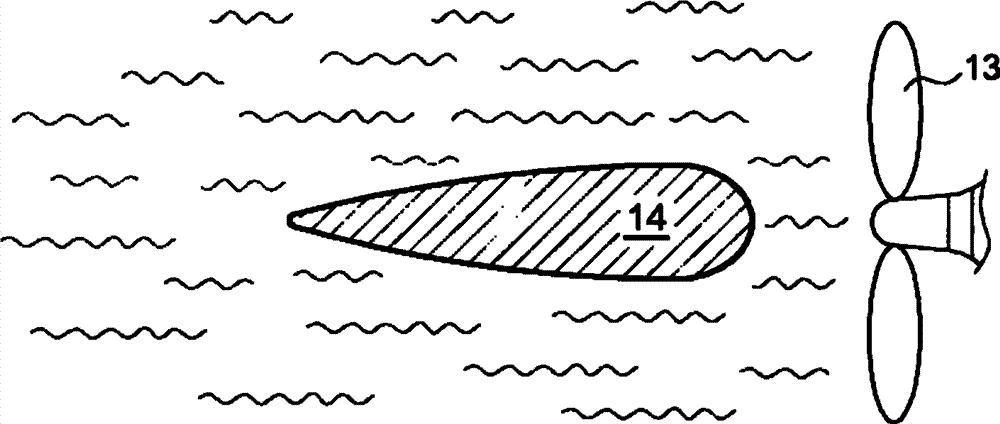

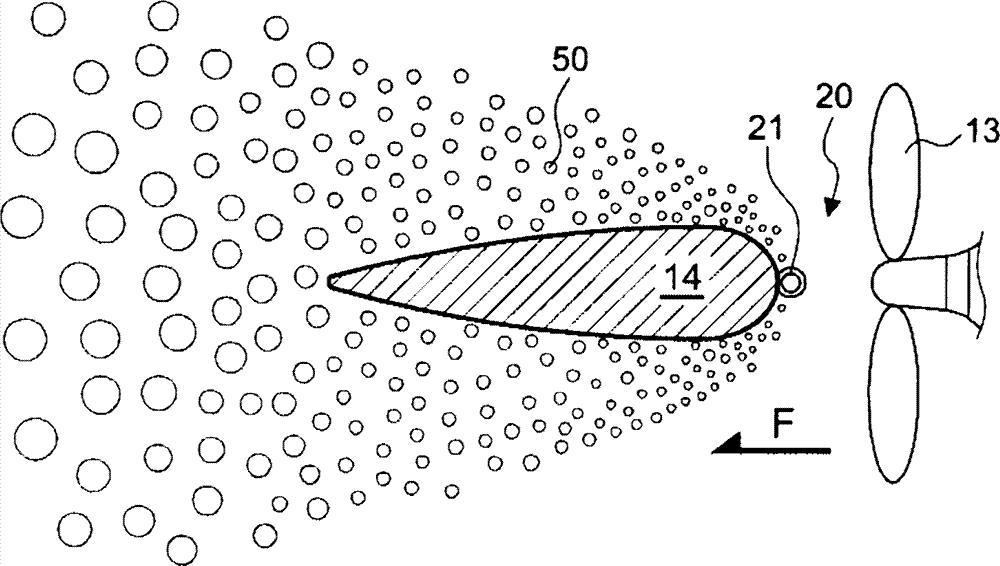

[0045] First, see Figure 3 ~ Figure 6 shown, where image 3 Shown is a schematic diagram that reveals that the gas bubbles 50 of the present invention reduce the resistance of the rudder, for use with figure 2 Existing ship rudder 14 surface resistance is compared; Figure 4 , Figure 5 Therefore, a preferred feasible embodiment of the present invention is disclosed, and its implementation steps and specific structure include:

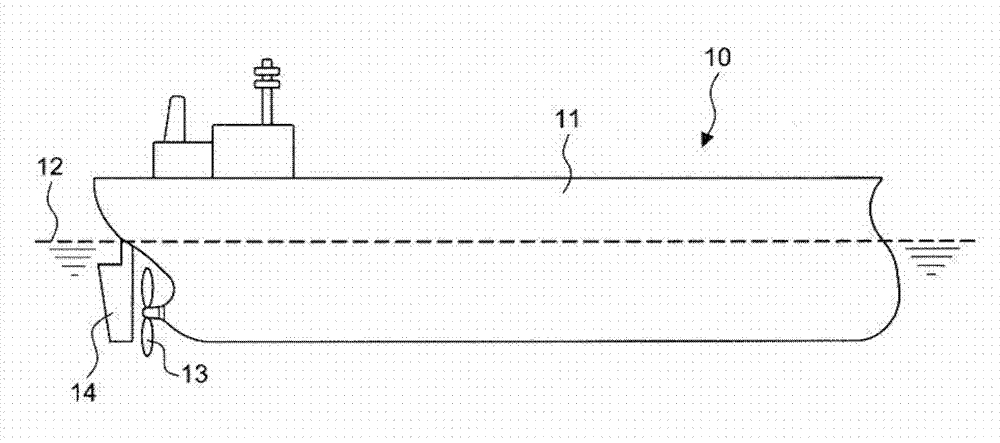

[0046] a) A ship 10 is provided. In this embodiment, the hull 11 of the ship 10 has a propeller 13, which is driven by a power engine 131, so that the propeller 13 sends out a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com