Device and method for horizontal gas well to drain liquid and produce gas

A liquid drainage gas production and gas well technology, which is applied in the direction of production fluid, earth drilling, wellbore/well components, etc., can solve the problems of loss of gravitational potential energy, loss of formation gas-carrying liquid energy, reduction of gas production, etc., to achieve reduction The effect of lowering the pump depth, reducing lifting energy consumption, and increasing air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

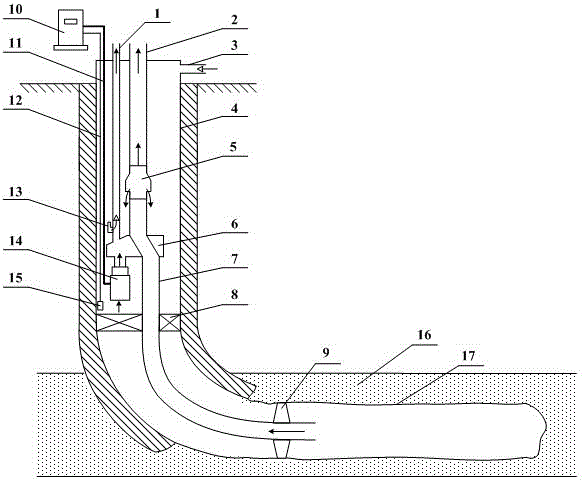

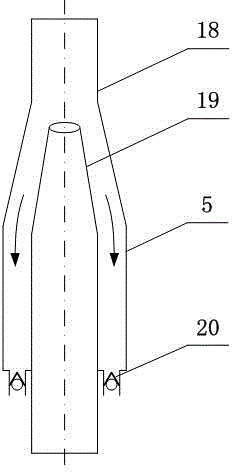

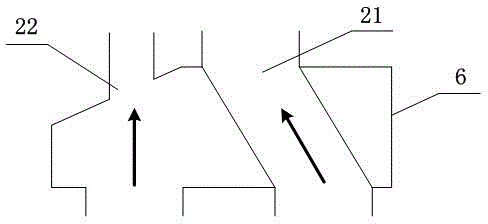

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a device for liquid drainage and gas production in horizontal gas wells, which mainly consists of liquid drainage thin pipe 1, upper oil pipe 2, ground gas injection pipe 3, casing pipe 4, shut-off device 5, special joint 6, and lower oil pipe 7 , packer 8, surface controller 10, cable 11, wire 12, gas lift valve 13, electric pump unit 14, downhole liquid level gauge 15. The upper tubing 2, shut-off device 5, special joint 6, and lower tubing 7 are sequentially connected in series to form an oil-casing annulus with the casing 4, and the upper part of the oil-casing annulus communicates with the ground gas injection pipe 3; the packer 8 will The vertical section is separated from the oil jacket annulus of the horizontal section; the intercepting device 5 is composed of an outer cylinder 18 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com