Double-cage rotor magnetic pump

A magnetic pump and rotor technology, applied in the field of double-cage rotor magnetic pumps, can solve the problems that cannot meet the requirements of different loads, it is difficult to realize the sinusoidal air gap magnetic field drive, and the starting and working performance cannot be satisfied, so as to reduce the starting time and reduce the Effect of Small Harmonic Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

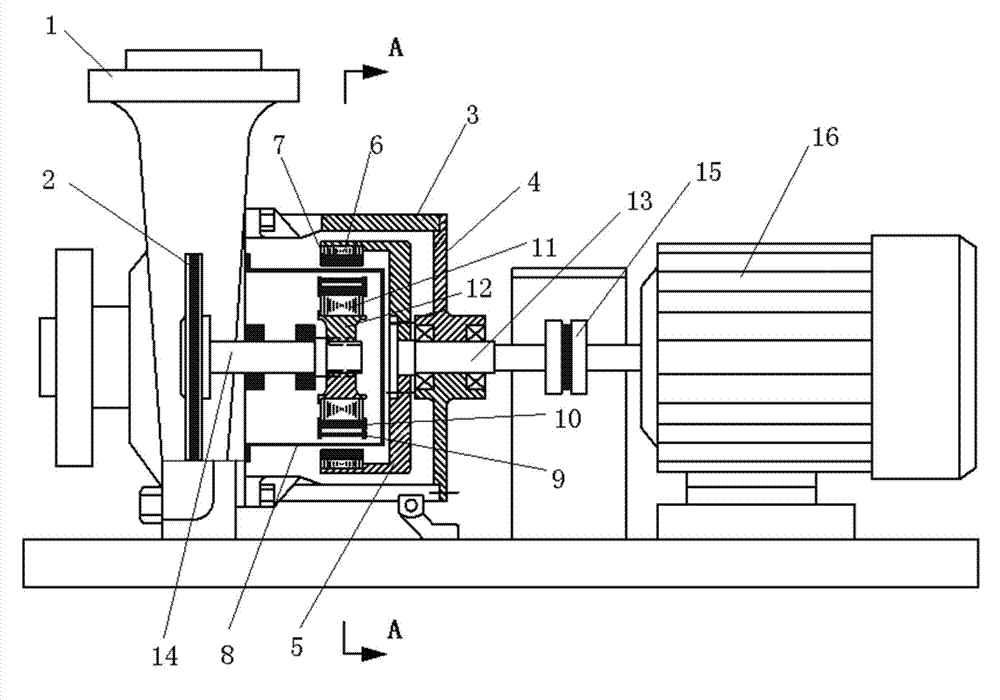

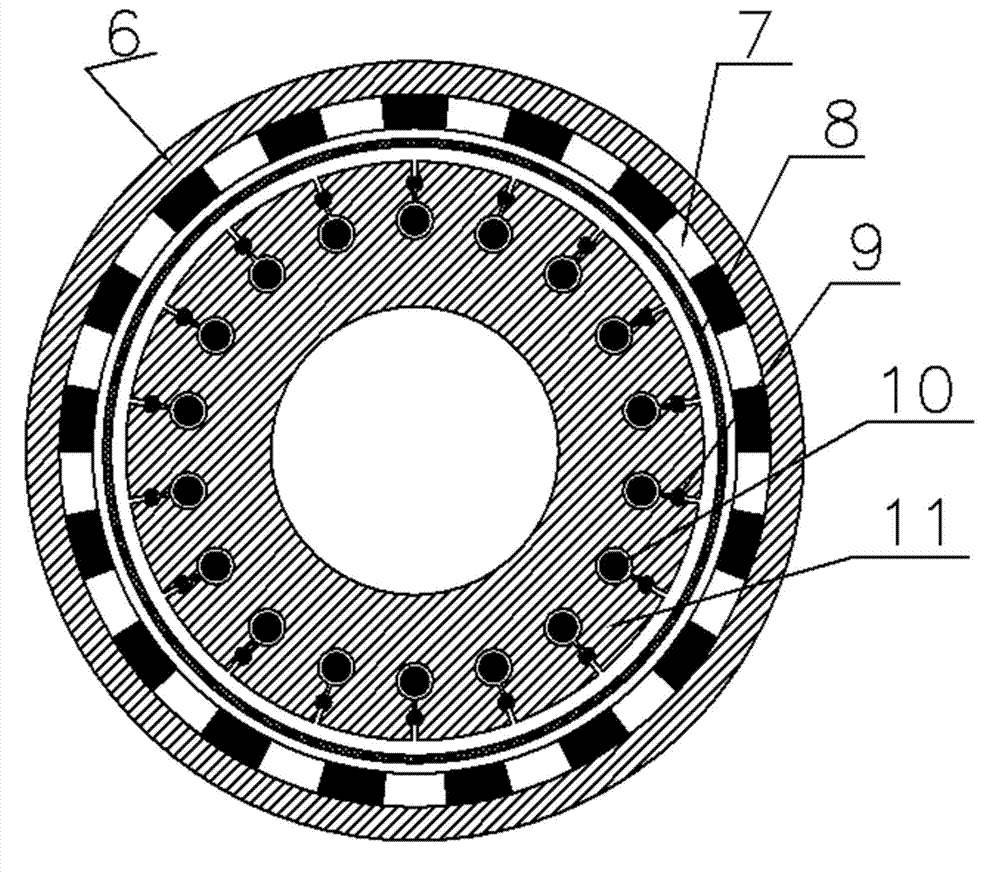

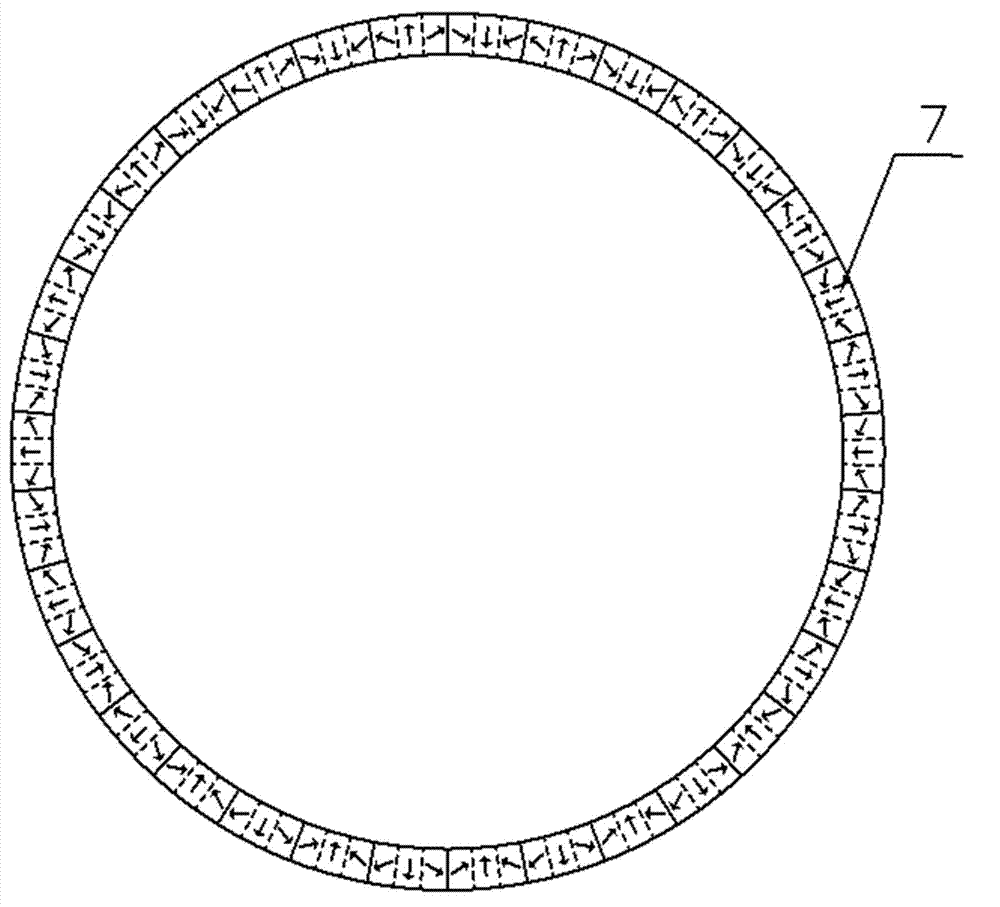

[0030] The specific implementation of the double-cage rotor magnetic drive pump of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] See attached figure 1 , 2 , 3. The double-cage rotor magnetic pump includes pump body 1 and casing 3. The casing 3 is installed on one side of the pump body 1, and a bearing seat is provided on one side of the casing 3, and the input is set through the bearing in the bearing seat. Shaft 13, in order to facilitate processing, one side of the housing 3 is an encapsulated end cover 4, the bearing seat is arranged on the end cover 4, the first end of the input shaft 13 is located inside the housing 3, and the second end of the input shaft 13 is in the It is connected to the rotating shaft of the motor 16 through a coupling 15 . The output shaft 14 is installed on the pump body 1 through bearing rotation, the first end of the output shaft 14 extends into the casing 3, the second end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com