Deflagration overpressure relief device with wave adsorption and flame suppression functions

A discharge device and flame suppression technology, which is applied in the direction of the valve's energy-absorbing device, valve device, and functional valve type, etc., can solve the problems of flame personnel, equipment surrounding environment threats, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

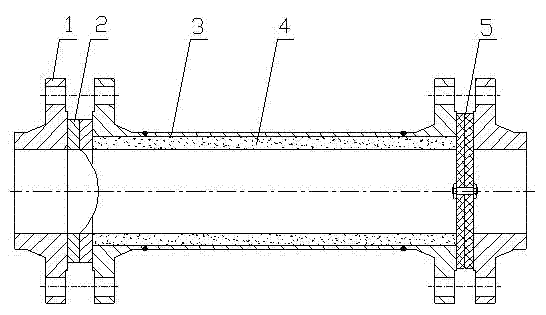

[0009] Example 1: A deflagration overpressure relief device with wave-absorbing and flame-extinguishing functions, consisting of a pipe flange 1, a bursting disc assembly 2, a relief pipe 3, an aluminum silicate wool porous material 4, and a fire-resistant corrugated plate 5 The bursting disc assembly 2 is installed at the joint of the pipe flange 1, the porous aluminum silicate cotton material 4 is attached to the inner wall of the discharge pipeline 3, and the fire-resistant corrugated plate 5 is installed at the end of the discharge pipeline 3.

[0010] refer to figure 1 , in this embodiment, when the explosion occurs in the protected container, if the pressure in the container reaches the burst pressure of the bursting disc assembly 2, the bursting disc assembly 2 will open, and the burned products, unburned medium, flame and pressure wave will all be released. to the drain line 3. In the discharge pipeline 3 , the pressure wave is absorbed by the aluminum silicate cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com