Radiating LED (Light Emitting Diode) module and LED down lamp

A technology of LED modules and LED downlights, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of heat accumulation and dissipating air, poor heat dissipation, and inability to solve the heat island effect, etc., to achieve Enhance heat dissipation effect, save cost and reduce own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

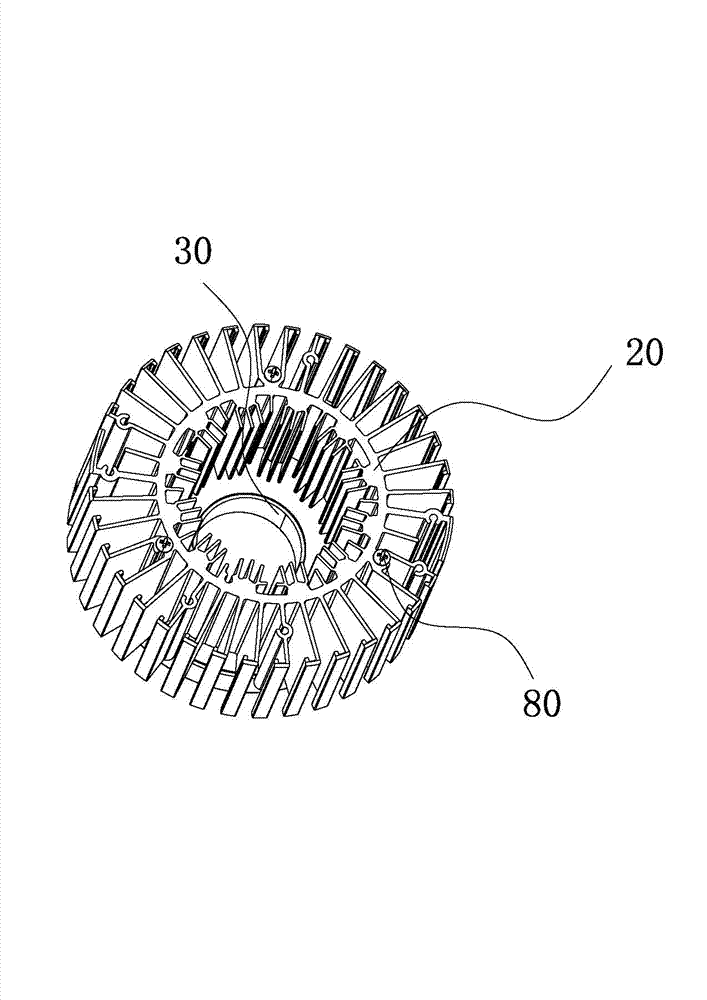

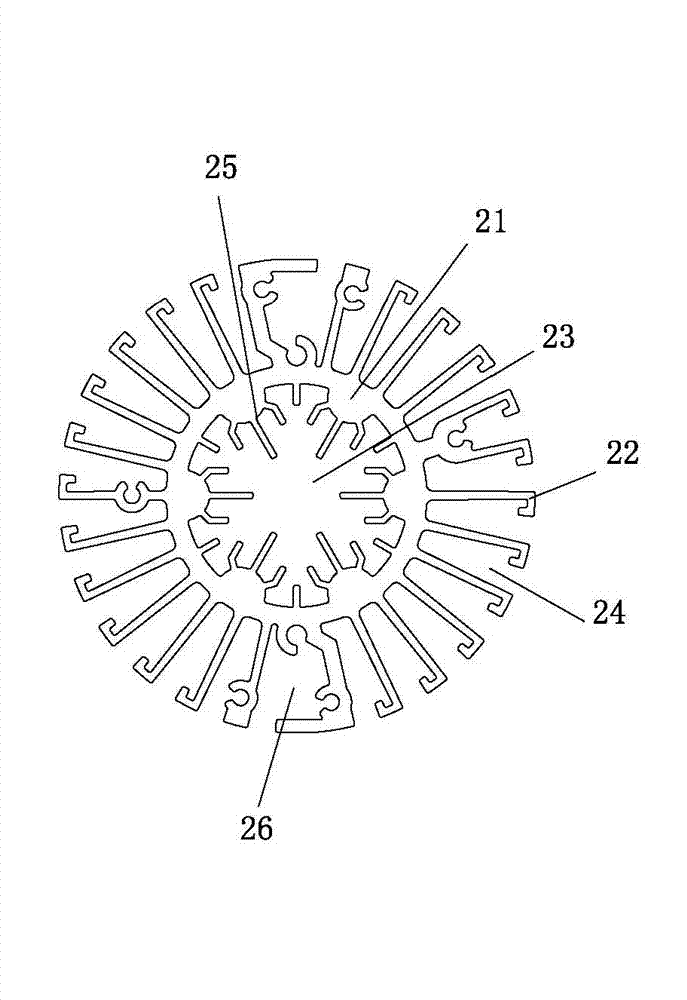

[0042] Such as Figure 1 to Figure 8 As shown, a heat dissipation LED module of the present invention includes: a heat sink 20 and an optical engine 30, and the heat sink 20 includes a cylinder cavity 21 and several pieces of heat dissipation ribs connected to the outside of the cylinder cavity 21 in longitudinal intervals. 22. Both ends of the cylinder cavity 21 are open to form an inner closed convection heat dissipation channel 23; adjacent heat dissipation ribs 22 are separated to form an open outer convection heat dissipation channel 24.

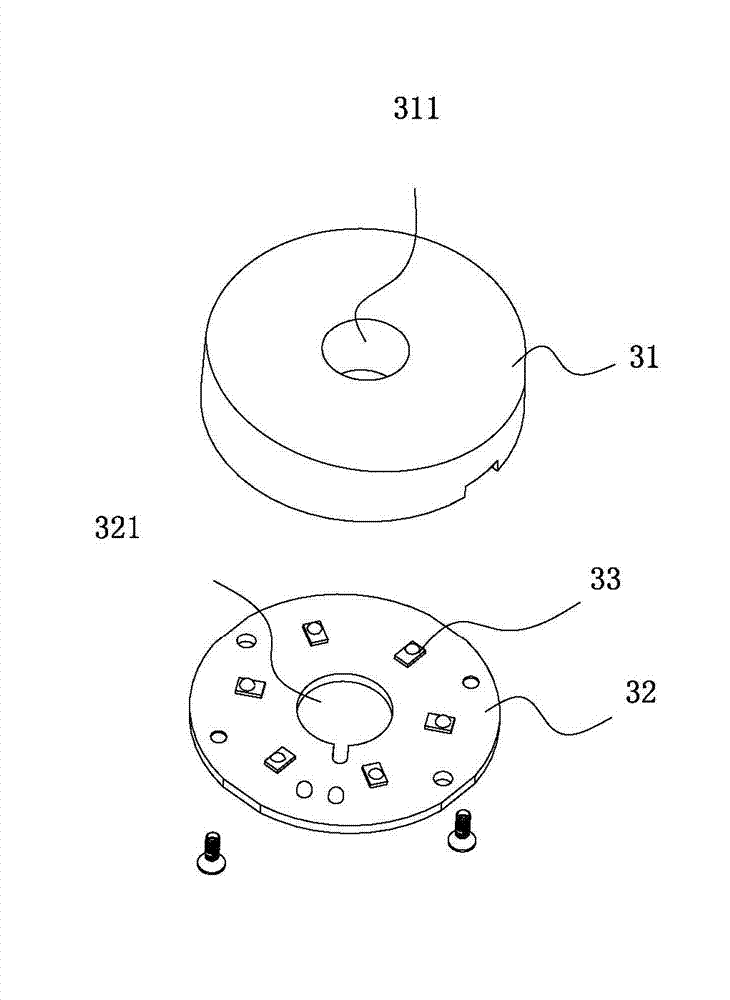

[0043] The optical engine 30 includes a module lens 31, an aluminum substrate 32 and several LEDs 33 arranged on the aluminum substrate 32. The center of the module lens 31 is provided with a module lens through hole 311, and the center of the aluminum substrate 32 is provided with an aluminum Substrate through hole 321, desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com