Polarizing element unit, transmittance setting method of polarizing element unit, light irradiation apparatus using same

A technology of a light irradiation device and a polarizing element, which is applied to polarizing elements, optical elements, diffraction gratings, etc., can solve the problems of poor transmittance and uneven illuminance distribution in the light irradiation area, and achieve the effect of uniform illuminance distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

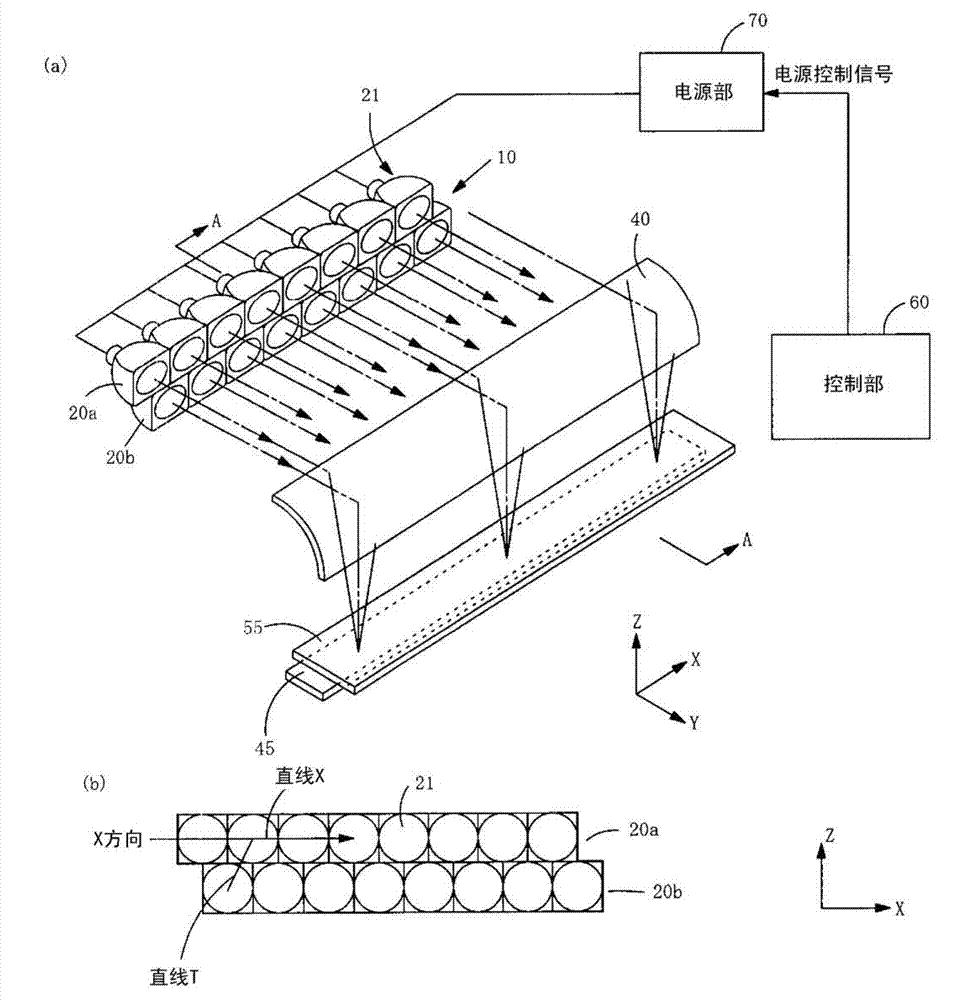

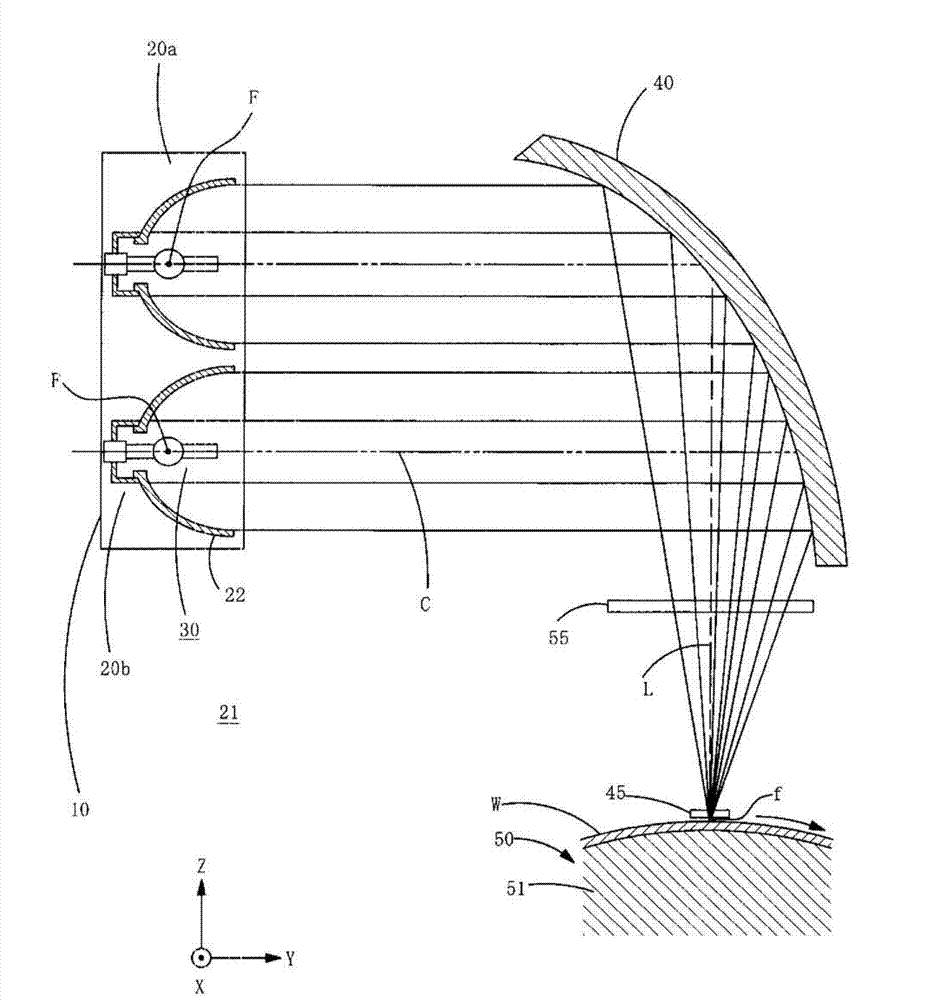

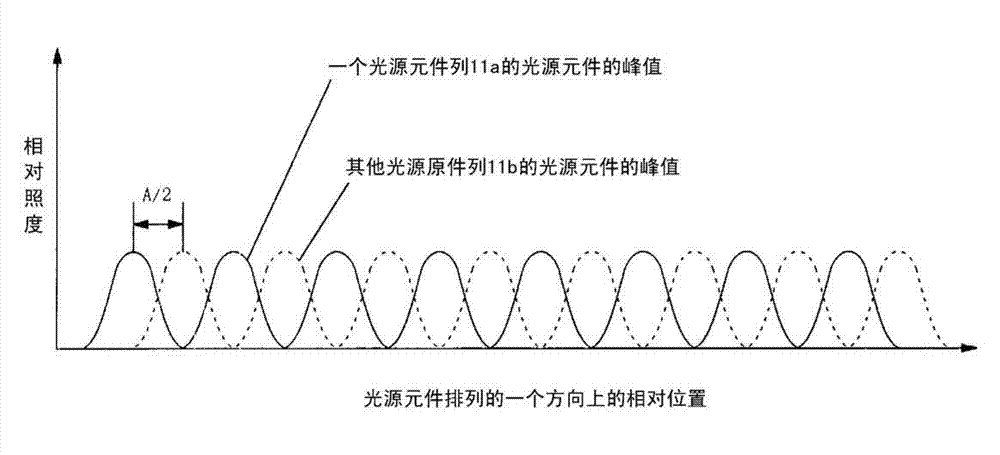

[0062] figure 1 is a diagram showing the overall schematic configuration of the light irradiation device according to the first embodiment of the present invention, figure 2 Yes figure 1 A-A cross-sectional view of the light irradiation device shown in (a). figure 1 (a) shows the overall schematic configuration of the light irradiation device, and FIG. 1(b) shows a view of the light emitting portion viewed from the light emitting side.

[0063] like figure 1 As shown in (a), the light irradiation device includes: a light emitting part 10; a reflecting mirror 40 that reflects the light from the light emitting part 10 and condenses the light into a line; and a polarizing element unit that polarizes the light reflected by the reflecting mirror 40 55; a mask 45 for shaping the polarized light from the polarizing element unit 55 into a striped shape; a power supply unit 70 for supplying electric power to the lamps of the light emitting unit 10; control unit 60 .

[0064] On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com