Salient pole type alternating current synchronous generator rotor bobbin

A technology for synchronous generators and rotor wires, applied in synchronous generators, electrical components, electromechanical devices, etc., can solve the problems of poor ventilation and heat dissipation at the end of the coil, short service life, and high temperature of the motor, so as to save materials and reduce Cost, the effect of reducing the temperature rise of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

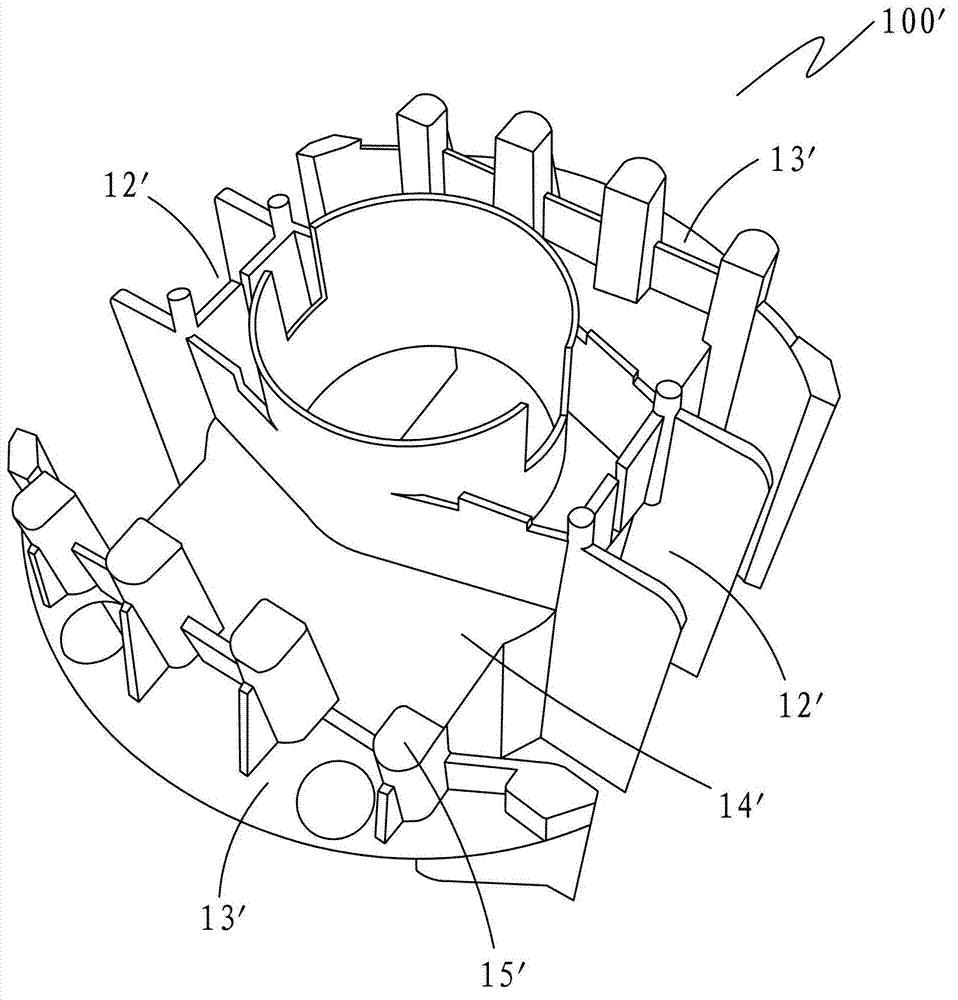

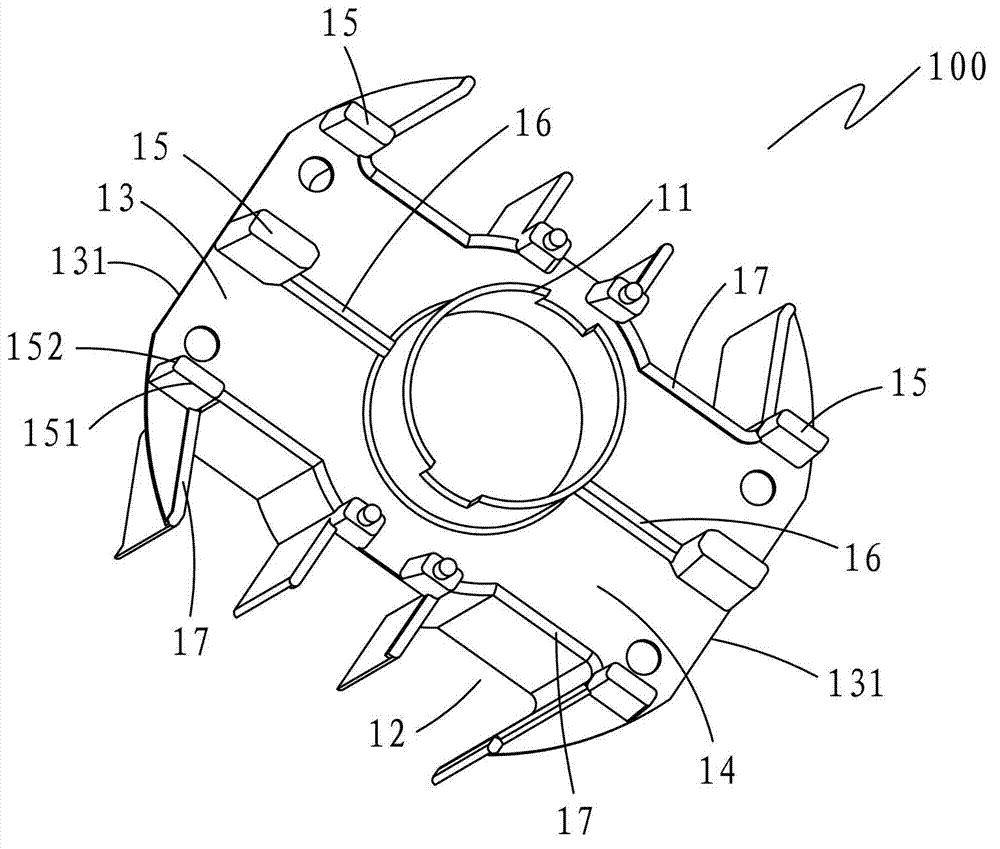

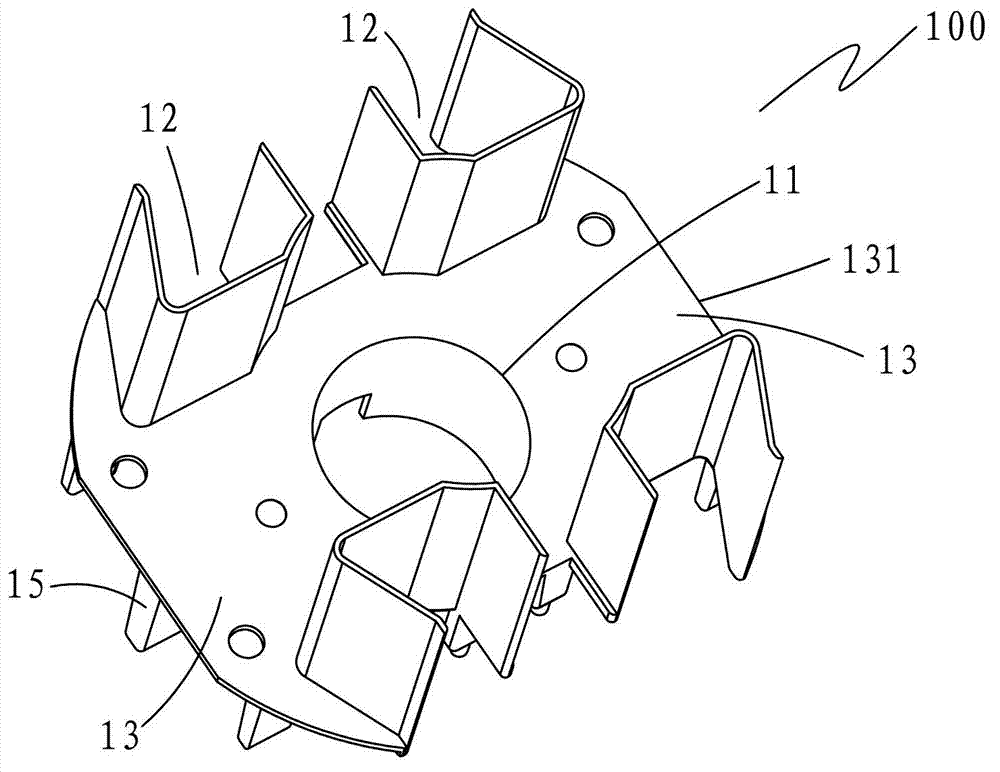

[0021] see Figure 2-3 , a salient pole AC synchronous generator rotor frame 100, including a frame body 1, the frame body 1 includes a shaft sleeve 11, four coil slots 12 and two pole segments 13; the outer body of the frame body 1 Six blades 15 are erected in parallel on the side 14, and the six blades 15 are arranged on the two magnetic pole segments 13 in pairs; the cross section of each blade 15 has a long side 151 and a short side 152, and the The short side 152 is arranged towards the outer periphery of the magnetic pole segment 13, so that the radial surface of the blade 15 is wider, but the outer contact surface between the blade 15 and the end of the coil (not shown) is smaller. This structure creates six The radial strength of the blade 15 is high, which can prevent the end of the coil from being thrown out under the centrifugal force, and at the same time, the outer surface of the coil is basically exposed to the air for heat dissipation. The function improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com