Rotary mop bucket

A technology of rotating mop and bucket body, which is applied in the field of mop bucket, which can solve the problems of dirty walls or furniture, sewage splashing outside, etc., and achieve the effect of small space occupation, exquisite structure design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

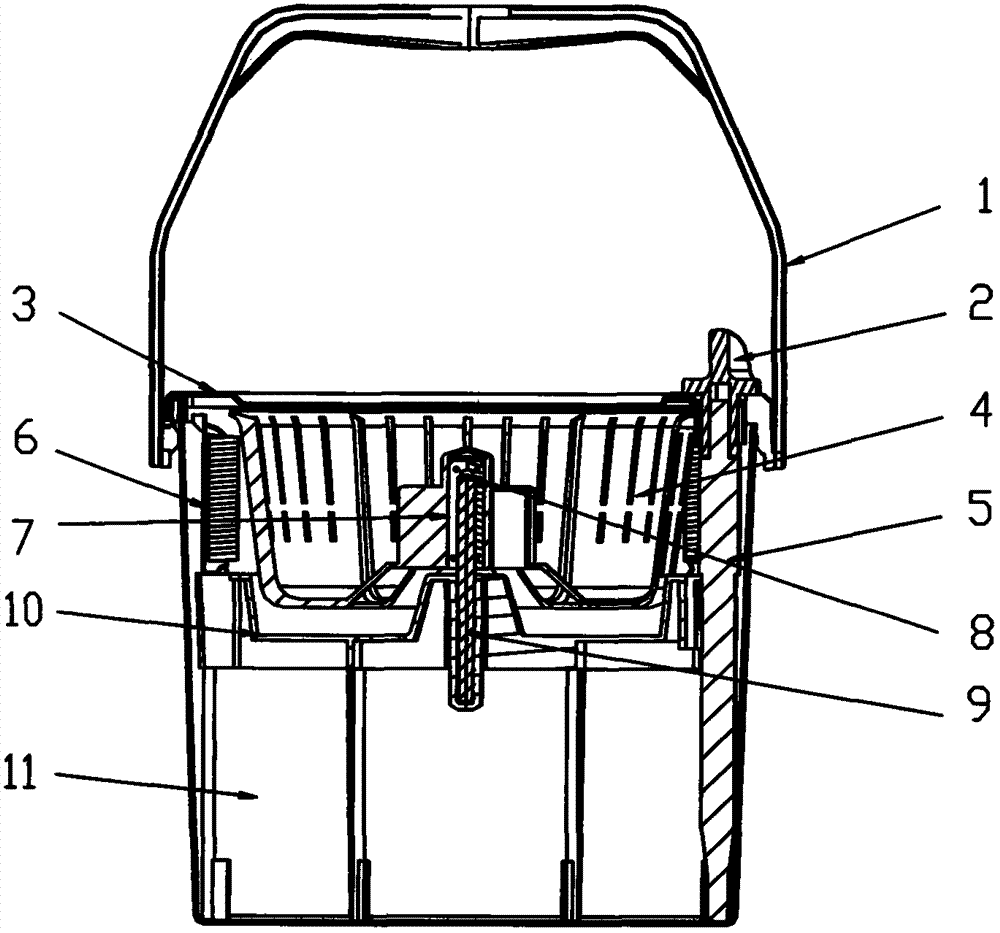

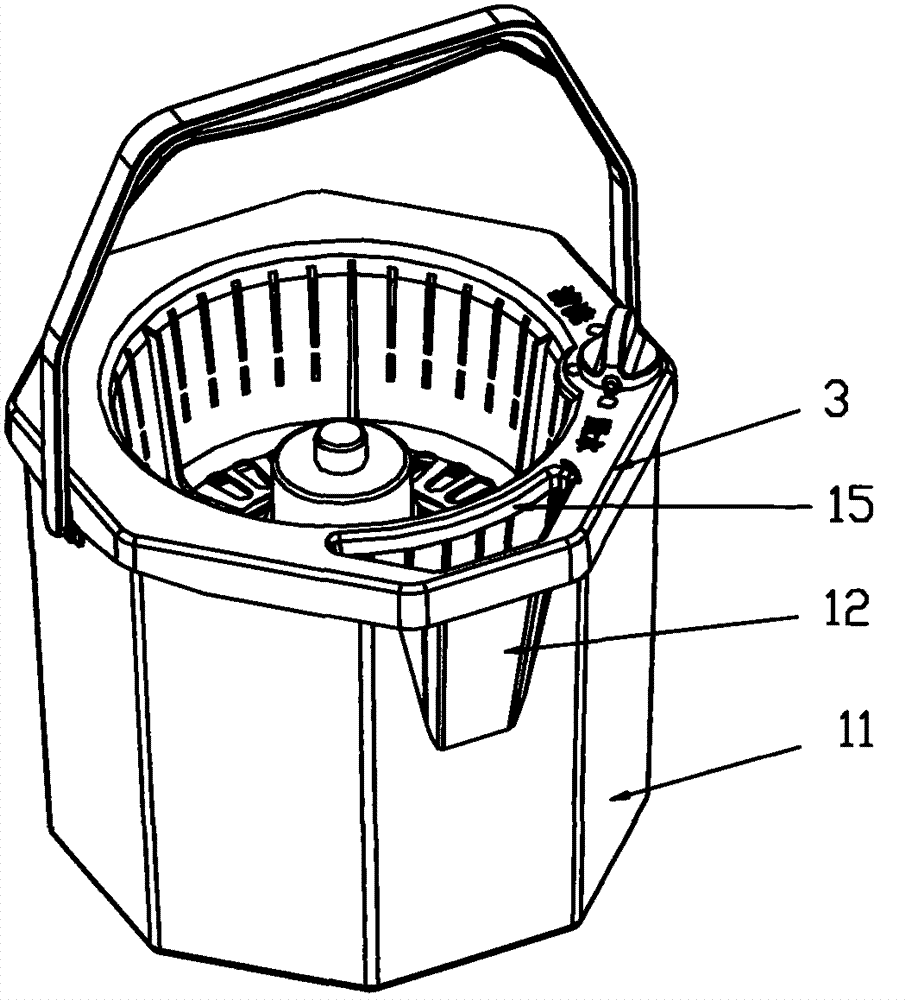

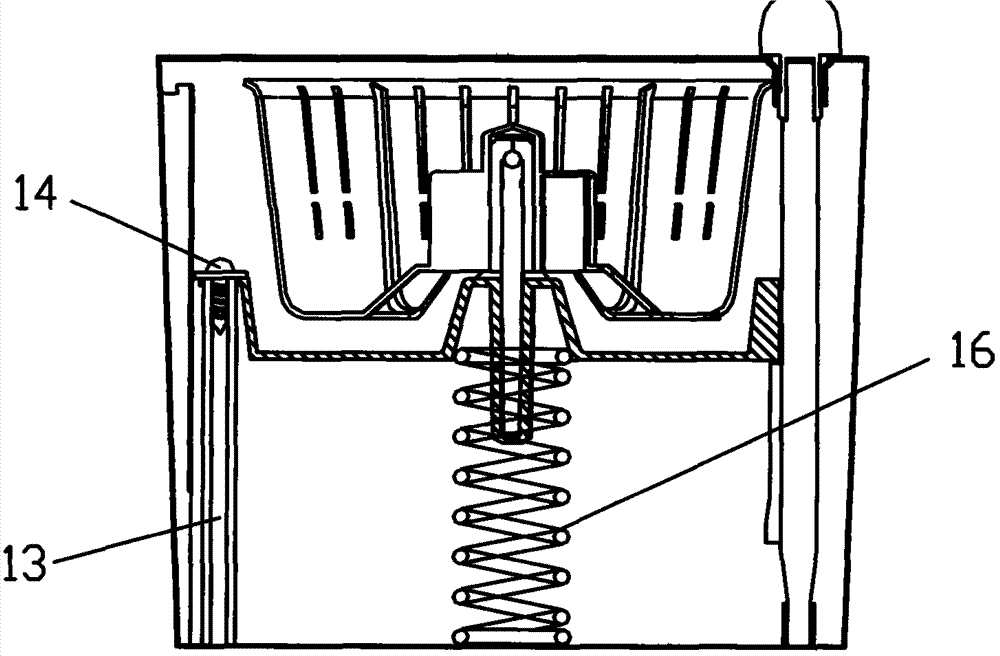

[0021] As shown in the figure, a rotary mop bucket includes a bucket body 11, the bucket body 11 is provided with a unilateral convex edge 12, and the top of the bucket body 11 is provided with a waterproof cover 3 and a handle 1 matched with it. A water outlet 15 is provided above the side convex edge 12, a dehydration basket 10 is provided at the bottom of the barrel body 11, a steel needle 9 is provided in a counterbore at the center of the dehydration basket 10, and a steel ball 8 is provided in a small groove at the top of the steel needle 9 , the basket core 7 buckled on the outside of the steel needle 9 is pressed on the steel ball 8, the basket core 7 is fixed in the large groove in the center of the dehydration basket 4, and the return spring-6 arranged on the barrel body 11 along both sides or at the bottom is in contact with the dehydration basket 11. The basket 10 is connected, and the side of the dehydration basket 10 is provided with a rotary adjustment rod 5 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com