Fluorocarbon metallic coating and manufacture method thereof

A technology of fluorocarbon metal paint and production method, which is applied in the field of paint, can solve the problems of expensive large-area application, easy to be corroded, and affect the appearance, and achieve excellent self-cleaning and anti-fouling properties, low cost, bright and beautiful colors Effect

Inactive Publication Date: 2013-03-13

铜仁市光彩漆业有限公司

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing ordinary paints obviously cannot meet these conditions of use, and are easily corroded, discolored and affect the appearance. However, some foreign metallic paints cannot be applied in large areas due to their high cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

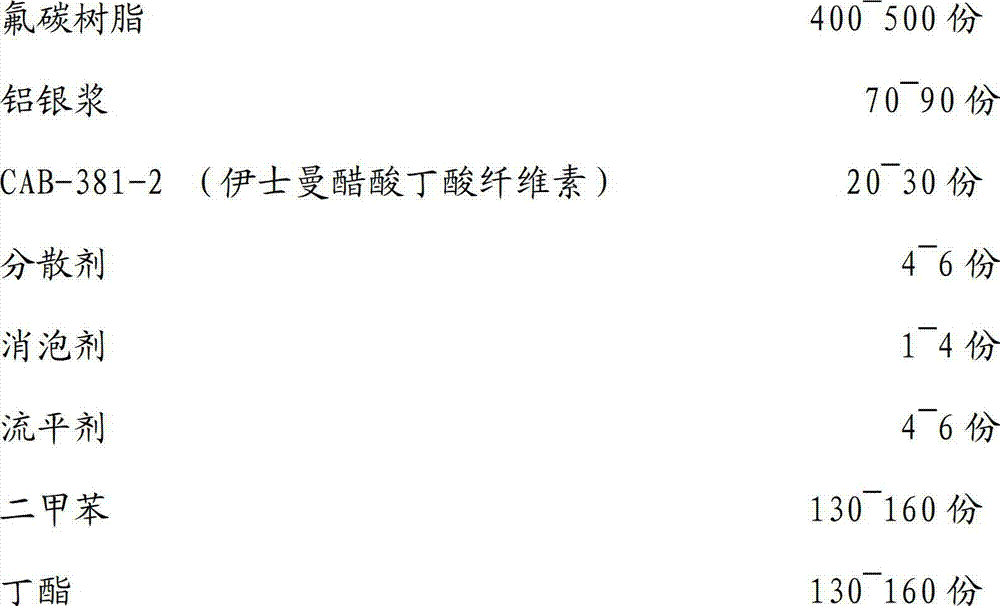

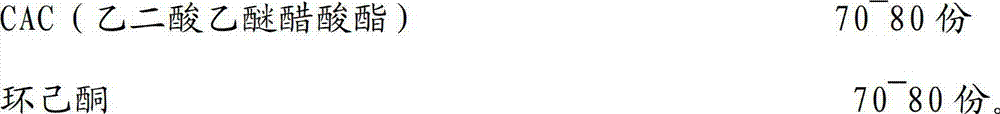

[0013] Fluorocarbon metallic paint, which is made of the following raw materials in parts by weight:

[0014]

[0015]

Embodiment 2

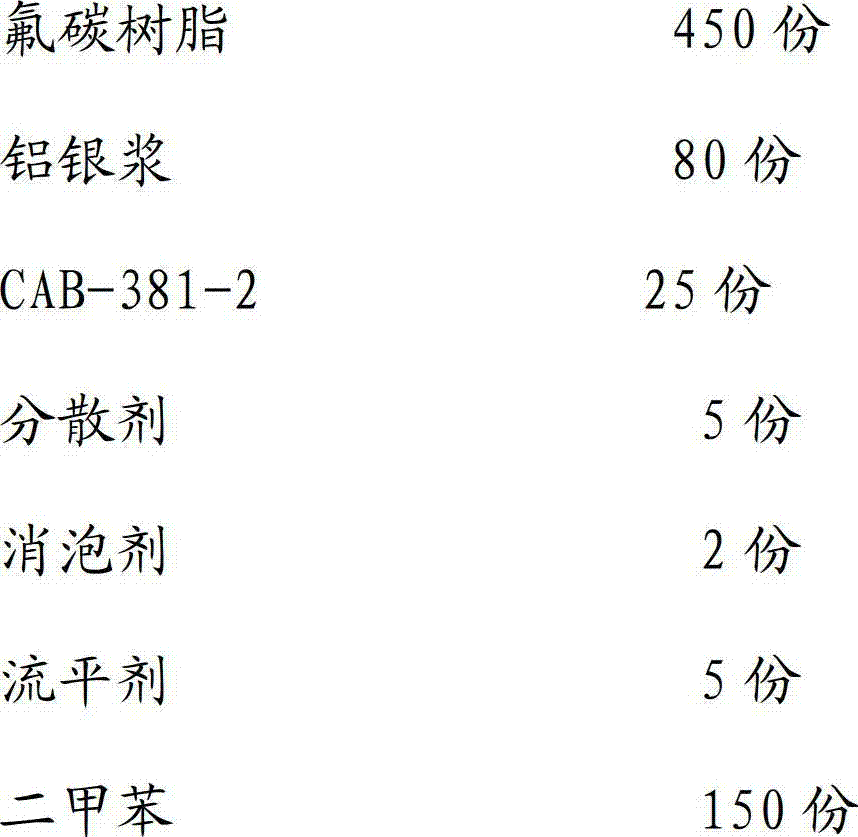

[0017] Fluorocarbon metallic paint, which is made of the following raw materials in parts by weight:

[0018]

Embodiment 3

[0020] Fluorocarbon metallic paint, which is made of the following raw materials in parts by weight:

[0021]

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a fluorocarbon metallic coating and a manufacture method thereof. The manufacture method comprises the steps of: adding dimethylbenzene, butyl ester, CAC (ethylene glycol monoethyl ether acetate), cyclohexanone, a dispersing agent and CAB-381-2 (Cellulose Acetate Butyrate) in a container, uniformly stirring; and then adding aluminum paste; after dispersing, adding fluorocarbon resin and grinding; adding a defoaming agent and a flatting agent, correcting viscosity, uniformly stirring; and weighing and packing after technical indexes are checked to be qualified. The manufacture method has the beneficial effects that with the fluorocarbon resin and the aluminum paste as main ingredients, in conjunction with a plurality of auxiliary function additives, the manufactured metal fluorocarbon coating is low in cost, has excellent weather-resistant property and chemical resistance, and excellent self-cleaning dirt resistance, and has the characteristic of bright and attractive color.

Description

technical field [0001] The invention relates to a fluorocarbon metal paint and a preparation method thereof, belonging to the technical field of paint. Background technique [0002] In some traffic vehicles, construction machinery, advanced instruments and equipment, cement walls, tiles, aluminum alloy walls and other objects requiring high-end decoration on the surface and outdoor environments, the requirements for the paint used are higher, and higher weather resistance is required. Performance and chemical resistance, excellent self-cleaning and stain resistance, bright and beautiful colors and long service life. And existing common paint obviously can't satisfy these conditions of use, is easily corroded, changes color and affects appearance, and some foreign metallic paints can't get the application of large area because of high cost. Contents of the invention [0003] The object of the present invention is to provide a fluorocarbon metal paint and a preparation meth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D127/12C09D7/12

Inventor 高方周徐华山李子银腾鹏

Owner 铜仁市光彩漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com