Apparatus and method for manufacture of paper and cardboards

A technology of cardboard and spraying device, applied in paper, wetting device, papermaking, etc., can solve problems such as forming error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

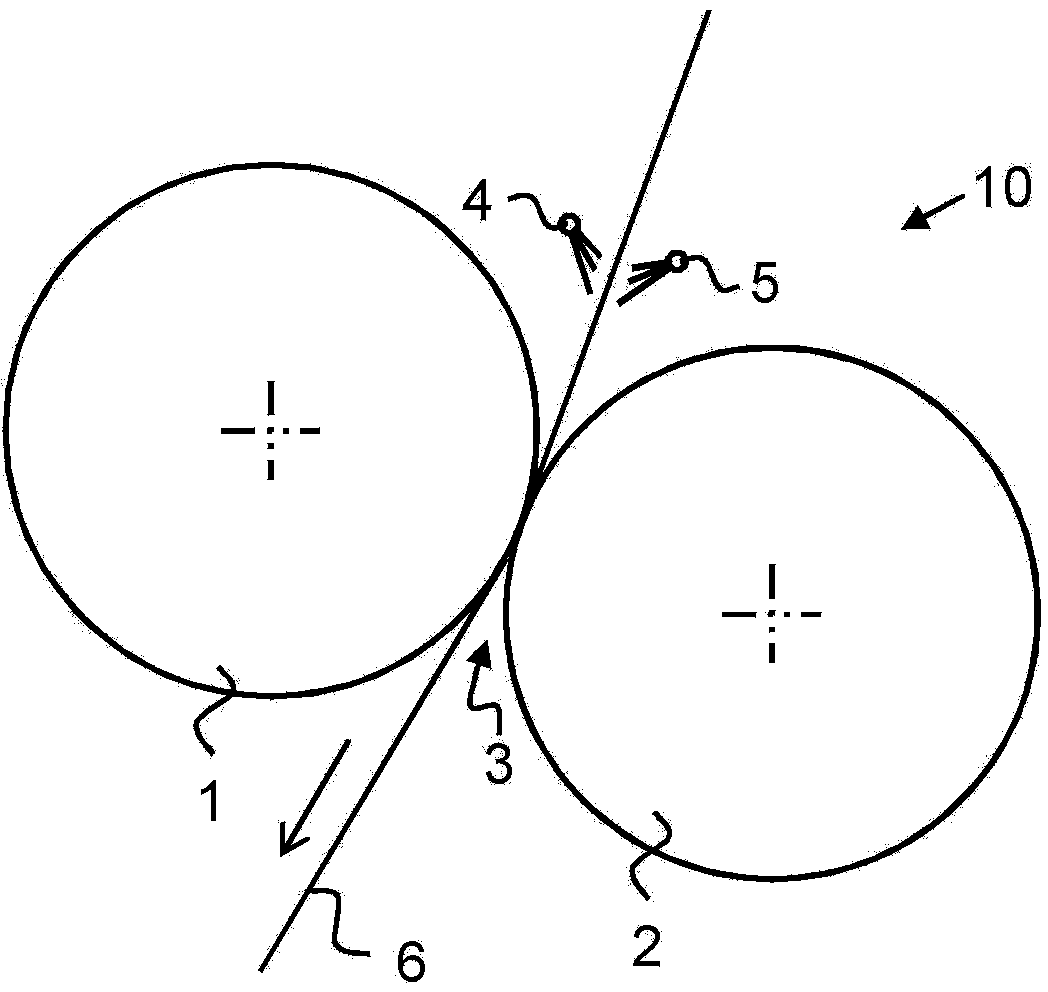

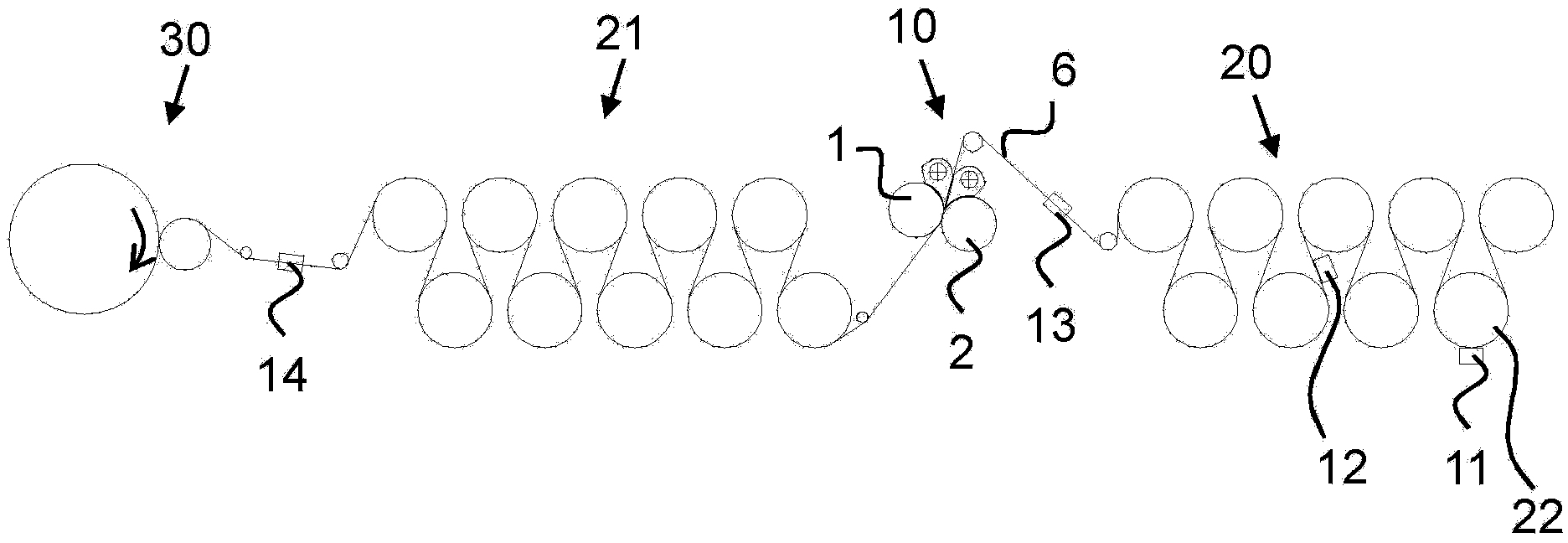

[0051] It is worth noting that the shown figures are not exactly to scale, they are only used to illustrate different embodiments of the invention.

[0052] exist figure 1 A spraying device 10 is shown in , which has two oppositely loaded pressing members, a first roll 1 and a second roll 2 . The extrusion members 1 , 2 form an extrusion nip 3 between them. The paper or cardboard web 6 is introduced into the press nip when a glue mixture with a higher solids content is to be sprayed onto the web. The spraying device 10 has a first nozzle 4 and / or a second nozzle 5 upstream of the extrusion nip. Using the glue mixture, the web is treated with glue on one or both sides by means of the first nozzle 4 and / or the second nozzle 5 .

[0053] The size is preferably sprayed on the web prior to the extrusion nip by means of a spraying device with nozzles.

[0054] It is also possible to use one or more belts as extrusion members. Preferably the belt is guided through the roll nip. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com