Connecting structure for maglev train rail

A technology for magnetic levitation trains and connecting structures, which is applied to tracks, roads, buildings, etc., can solve the problems of many additional parts, difficult processing, and low processing efficiency, and achieve the effects of easy processing and production, reduced production costs, and increased connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

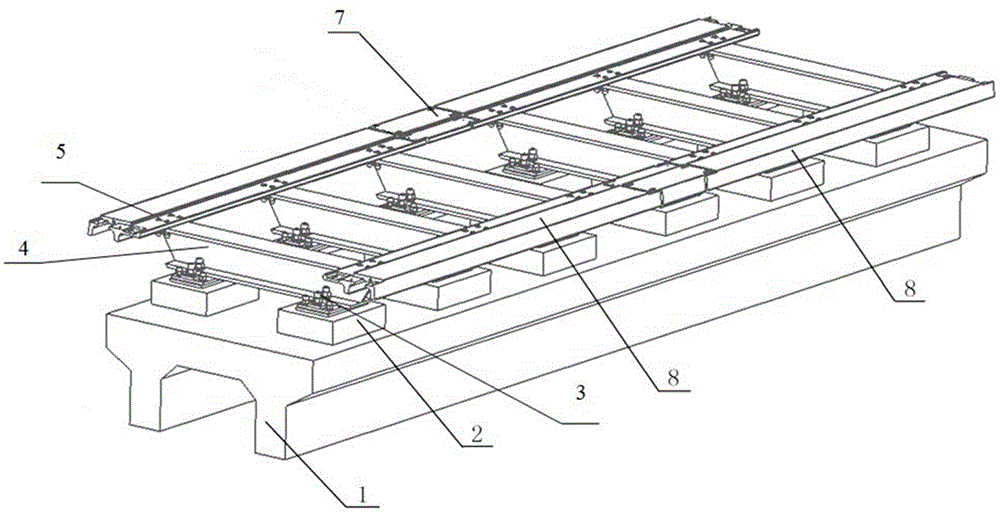

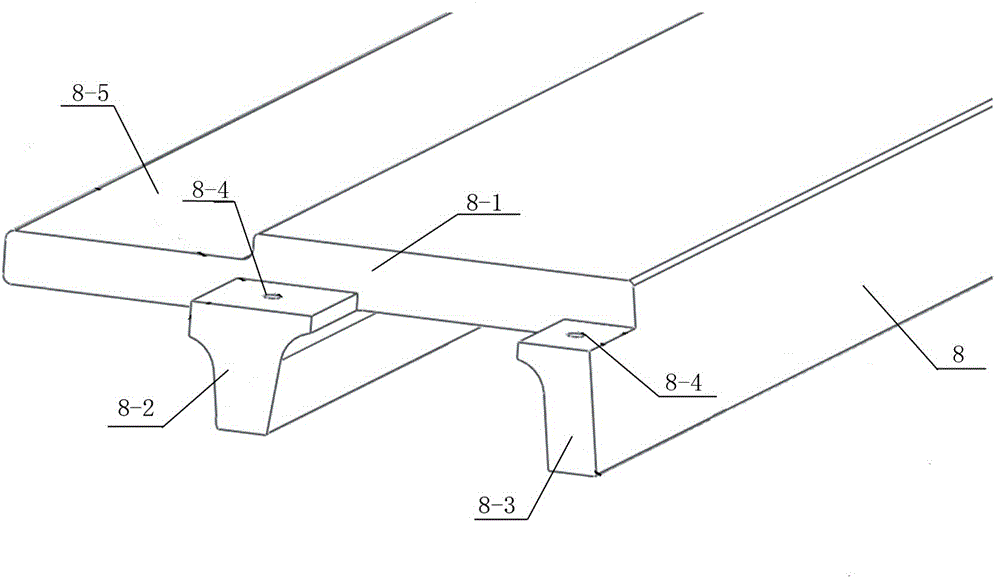

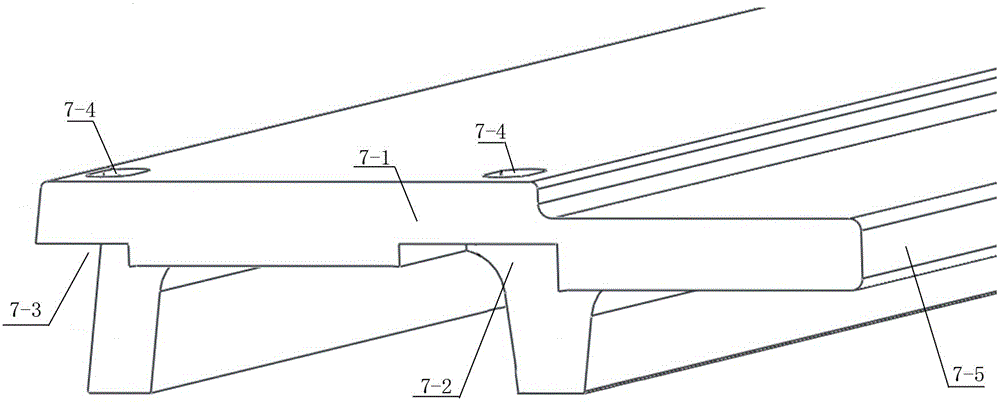

[0025] Such as figure 1 As shown, the structure schematic diagram of rail row for maglev train in the present invention is provided, which includes concrete track beam 1, bearing stand 2, fastener group 3, sleeper 4, sleeper connecting bolt 5, auxiliary F rail 7, main F rail 8; The concrete track beam 1 shown plays the role of fixing and supporting, the bearing platform 2 is evenly fixed on the upper surface of the concrete track beam 1, and both ends of the sleeper 4 are fixed on the bearing platform 2 through the fastener group 3 . The sleeper 4 realizes direct support to the main F rail 8 and the auxiliary F rail 7, and the main F rail 8 and the auxiliary F rail 7 are fixed on the sleeper 4 through the sleeper connecting bolt 5; the main F rail 8 and the auxiliary F rail 7 are arranged at intervals, and Two parallel rail rows are formed for the norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com