Latticed lead extrusion damper

A lattice type and damper technology, which is applied to building components, earthquake resistance, etc., can solve the problems of unusable dampers, energy consumption or poor effect of building structures, and achieves simple production and installation, high material utilization, and energy consumption effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

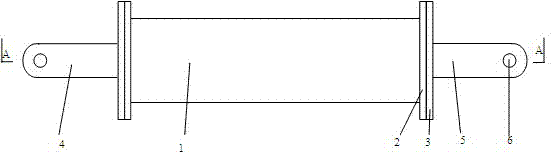

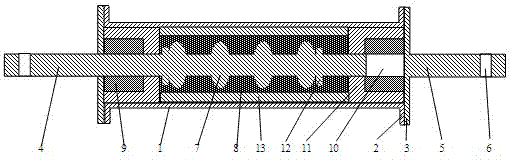

[0016] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

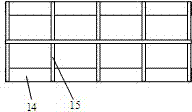

[0017] The lattice type lead squeeze damper that the present invention proposes is as Figure 1~Figure 4 shown. The whole device is mainly composed of outer cylinder 1, end plate reinforcement plate 2, end plate 3, movable shaft 4, fixed shaft 5, connecting earring 6, lead extrusion port 7, lead 8, sealing ring 9, movable shaft guide tube 10, The limit support 11, the limit baffle plate 12, the lattice frame 13, the longitudinal lattice plate 14 and the transverse lattice plate 15 etc. are composed. Both ends of the outer cylinder 1 are provided with an end plate reinforcing plate 2 and an end plate 3, and both ends of the inner cylinder of the outer cylinder (1) are provided with a sealing ring 9 and a limit support 11. A movable shaft 4 is arranged on one side, and a fixed shaft 5 is arranged on the other side to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com