Graphical transport layer, organic light-emitting diode(OLED) device containing graphical transport layer and preparation method

A transmission layer and patterning technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of loss of effective light-emitting area, complex structure, and reduced luminous intensity of OLED devices, so as to improve light output efficiency , The effect of maximizing the luminous area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

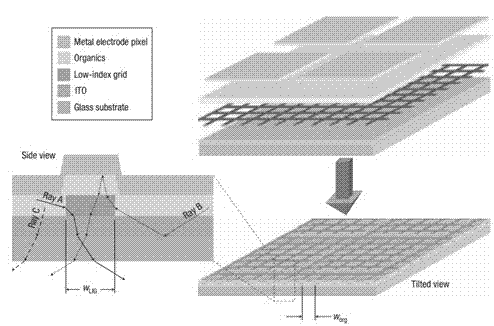

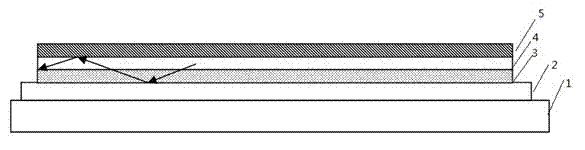

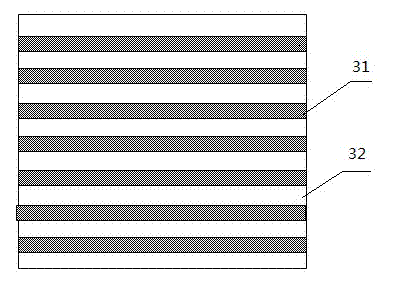

[0062] This embodiment provides a patterned transmission layer, the patterned transmission layer includes a conductive high-refractive-index region and a conductive low-refractive-index region, and the difference in refractive index between the high-refractive-index region and the low-refractive-index region is Value > 0.2. As a preferred implementation manner, the difference in refractive index between the high refraction region and the low refraction region can be selected to be >0.3. As a possible implementation manner, the refractive index of the high refractive index region is between 1.8-3.0; the refractive index of the low refractive index region is between 1.6-2.3.

[0063] In this embodiment, the high refractive index region is made of high refractive index material NPB with a refractive index of 1.8; the low refractive index region is made of NPB with a refractive index of 1.8 and MgF with a refractive index of 1.3. 2 Prepared by mixing, wherein NPB with a refractiv...

Embodiment 2

[0069] The OLED device in this embodiment has the same structure as the OLED device in Embodiment 1;

[0070] The preparation method is also the same, except that when preparing the patterned transmission layer, the low refractive index region uses NPB with a refractive index of 1.8 and MgF with a refractive index of 1.3. 2 Prepared by mixing, wherein NPB with a refractive index of 1.8 accounts for 70 parts by weight, and MgF with a refractive index of 1.3 2 Accounting for 30 parts by weight.

Embodiment 3

[0072]The OLED device in this embodiment has the same structure as the OLED device in Embodiment 1;

[0073] The preparation method is also the same, except that when preparing the patterned transmission layer, the low refractive index region uses NPB with a refractive index of 1.8 and MgF with a refractive index of 1.3. 2 Prepared by mixing, wherein NPB with a refractive index of 1.8 accounts for 50 parts by weight, and MgF with a refractive index of 1.3 2 Accounting for 50 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com