Single-drive bidirectional disk-shaped linear piezoelectric motor

A piezoelectric motor and disk-shaped technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve small size, affect the focusing effect, and contain components Miniaturization and simplification, better miniaturization and simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

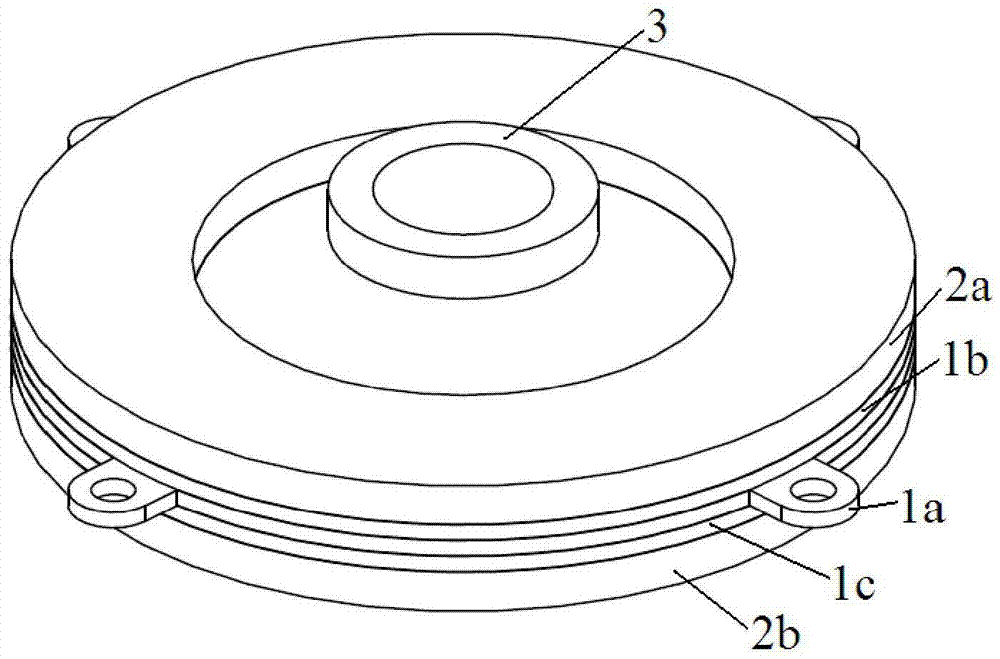

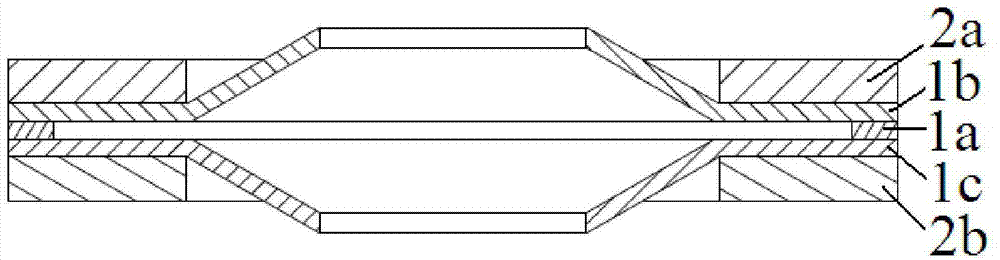

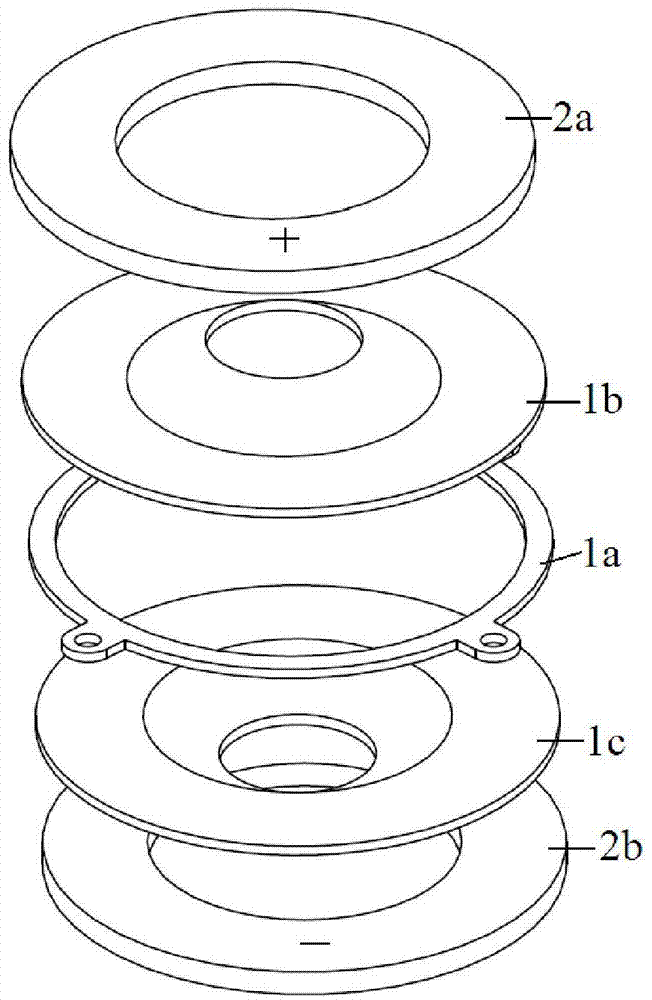

[0043] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the single-drive bidirectional disc-shaped linear piezoelectric motor of the present invention includes a stator and a mover 3 that can slide relative to the stator. The stator is composed of a vibrating body, two annular piezoelectric ceramic sheets 2a and an annular piezoelectric Composed of ceramic pieces 2b, the vibrating body is composed of an annular fixed bracket 1a and two identical bowl-shaped ring pieces 1b and 1c. The bowl-shaped ring piece 1b is provided with a protrusion 4a, and the center of the protrusion 4a is provided with Through holes, the bowl-shaped ring piece 1c is provided with a protrusion 4b, and the center of the protrusion 4b is provided with a through hole, and the protruding directions of the protrusion 4a and the protrusion 4b are opposite; the two bowl-shaped ring pieces 1b and the bowl-shaped ring piece 1c are pasted symmetrically On both sides of the fixed bracket 1a and ...

Embodiment 2

[0046] Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the single-drive bidirectional disc-shaped linear piezoelectric motor of the present invention includes a stator and a mover 3 that can slide relative to the stator. Composed of 2b, arc-shaped piezoelectric ceramic sheet 2c, arc-shaped piezoelectric ceramic sheet 2d, arc-shaped piezoelectric ceramic sheet 2e, arc-shaped piezoelectric ceramic sheet 2f, arc-shaped piezoelectric ceramic sheet 2g, and arc-shaped piezoelectric ceramic sheet 2h , the vibrating body is composed of a ring-shaped fixed bracket 1a and two identical bowl-shaped ring pieces 1b and 1c. The protruding directions of the bowl-shaped protrusions of the two bowl-shaped ring pieces are opposite. The central part of the shape protrusion is provided with a through hole; the protrusion part of the bowl-shaped ring piece 1b and the ring are mostly divided into the equivalent ring fan-shaped structure 4a, ring fan-shaped structure 4b, ring fa...

Embodiment 3

[0049] Such as Figure 9 , Figure 10 , Figure 11 and Figure 12As shown, the single-drive bidirectional disc-shaped linear piezoelectric motor of the present invention includes a stator and a mover 3 that can slide relative to the stator. Composed of 2b, arc-shaped piezoelectric ceramic sheet 2c, arc-shaped piezoelectric ceramic sheet 2d, arc-shaped piezoelectric ceramic sheet 2e, arc-shaped piezoelectric ceramic sheet 2f, arc-shaped piezoelectric ceramic sheet 2g, and arc-shaped piezoelectric ceramic sheet 2h , the vibrating body body is a ring-shaped fixed bracket 1, and the inner ring of the ring-shaped fixed bracket 1 is provided with four pairs of opposite arc-shaped protrusions 4a, arc-shaped protrusions 4b, arc-shaped protrusions 4c and circular arc-shaped protrusions. For the arc-shaped protrusion 4d, the protruding directions of the two opposite protrusions are consistent, that is, the protruding directions of the arc-shaped protrusion 4a and the arc-shaped protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com