MW-stage cage-type asynchronous machine starting circuit and method

A technology of starting circuit and soft starting circuit, applied in electrical components, motor generator control, control system, etc., can solve problems such as uncontrolled, large starting current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

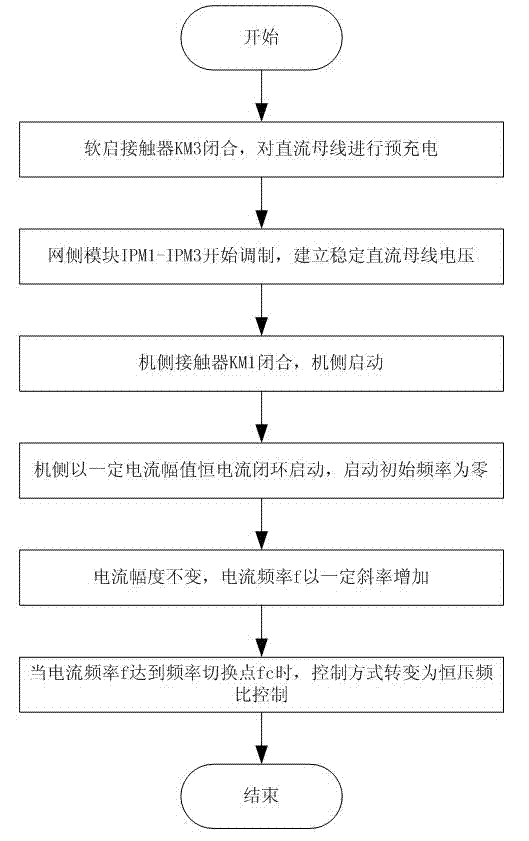

[0019] Description will be made below in conjunction with the accompanying drawings.

[0020] Startup circuit embodiment

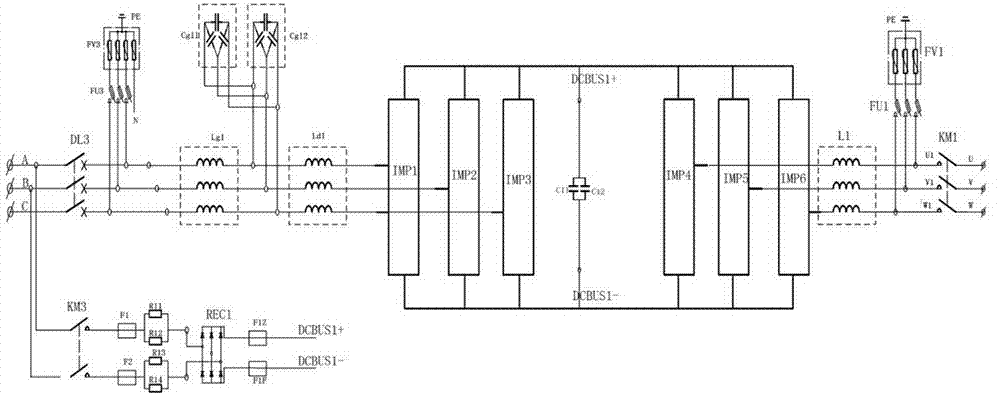

[0021] like figure 1 , The MW-level starting circuit of the present invention is mainly composed of a MW-level full-power converter (two parts of the grid-side converter and the machine-side converter) and a soft-start circuit. The grid-side converter realizes the stable control of the DC bus voltage and the unit power factor control of the AC input current, and the machine-side converter is connected with the stator of the cage-type asynchronous machine to realize the start-up and speed regulation control of the MW-level asynchronous motor.

[0022] The grid-side converter is mainly composed of three half-bridge power modules IPM1, IPM2, and IPM3. Ld1, Lg1, Cg11, and Cg12 are grid-side second-order filters; soft-start contactor KM3, soft-start resistors R11-R14, rectifier Bridge REC1, a soft start circuit composed of F1-F2; DL3 is a circuit breaker at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com