Bra cup

A cup and bra technology, which is applied in the field of novel bra cup structure, can solve problems such as difficult to achieve satisfactory accuracy and defective products, and achieve the effect of maintaining wearing comfort, improving yield, and not easily deformed or wrinkled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

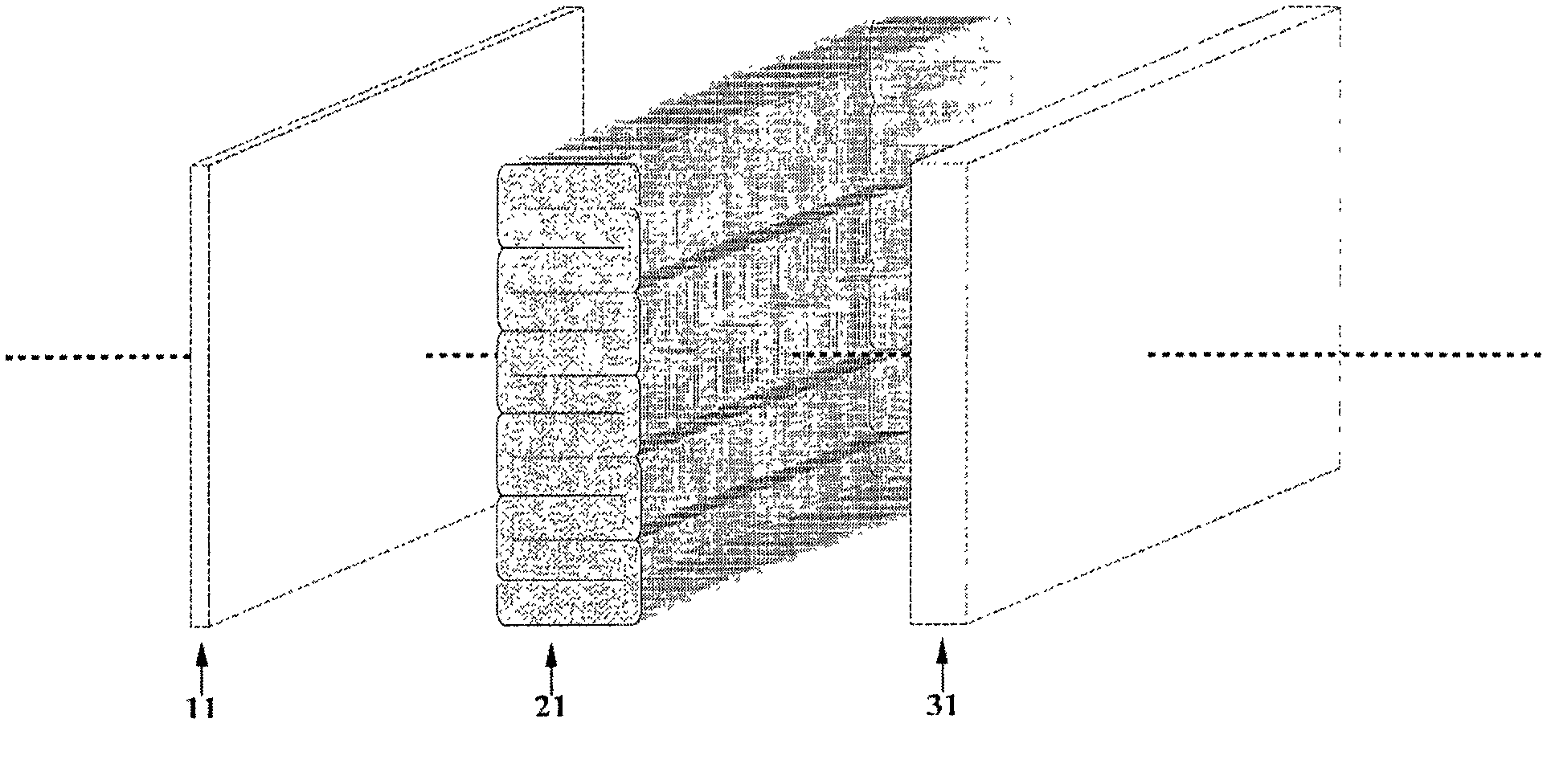

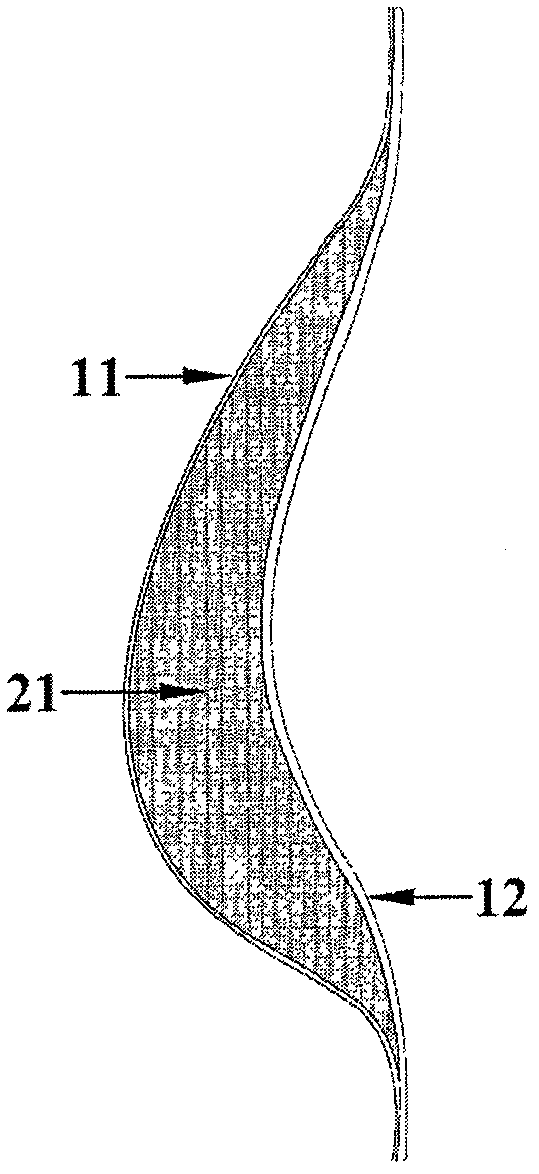

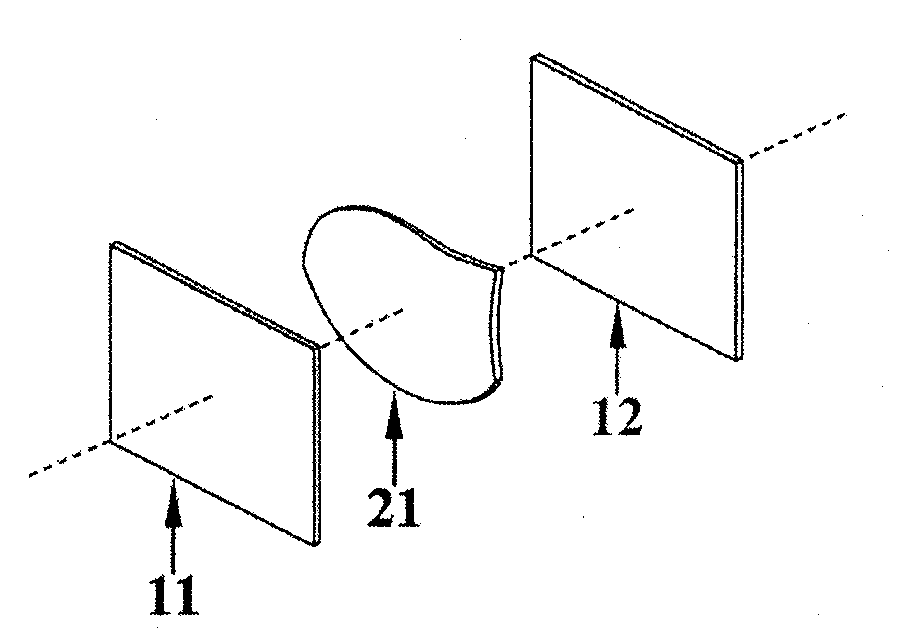

[0039] figure 1 The internal structure of the elastic upright honeycomb fiber cotton is shown, especially the orientation of the centerline of the man-made crimped fiber filaments. Figure 2-4 Shown is the brassiere cup of prior art, and its structure comprises outer surface fabric layer 11, inner surface fabric layer 12 and the elastic standing type honeycomb fiber cotton layer 21 sandwiched between outer surface fabric layer 11, inner surface fabric layer 12 .

[0040] The structure of the brassiere cup of the present invention comprises an outer surface cloth layer, a slow-rebound polyurethane foam layer, and a fiber cotton interlayer sandwiched between the outer surface cloth layer and the slow-rebound polyurethane foam layer, and the structure is formed by hot pressing Or cut and sew to get three-dimensional cups.

[0041] Polyurethane slow rebound foam has the characteristics of gradually and slowly returning to its original shape after being released from the compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com