Paraffin reaction kettle

A technology of reactor and reactor body, applied in the direction of chemical/physical/physicochemical fixed reactors, etc., can solve problems such as unbalanced force, affecting service life, complicated heating methods, etc., to achieve easy movement, convenient operation, Heating temperature control is convenient and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

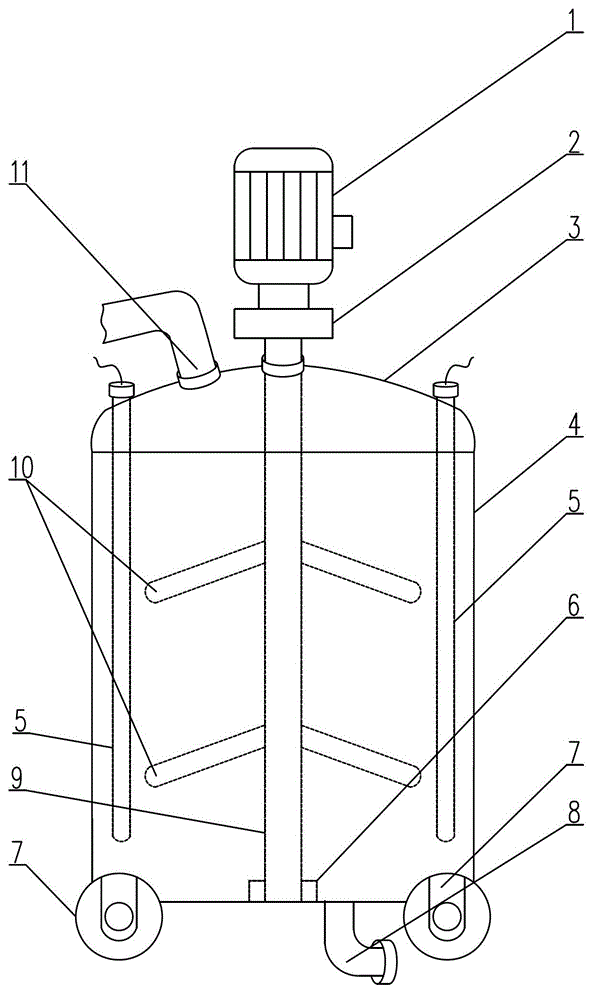

[0012] like figure 1 A kind of paraffin reactor shown, comprises reactor body 4 and kettle cover 3; The bottom of described reactor body 4 is provided with discharge pipe 8; The top of described kettle cover 3 is provided with feed pipe 11; Described reactor The center of the body 4 is provided with a stirring shaft 9 with one end connected to the bottom of the reactor body 4 through a bearing seat 6; The rotating shaft is connected; the stirring shaft 9 is equipped with a number of stirring blades 10; the kettle cover 3 is also provided with an electric heating rod 5 extending into the reactor body 4 and located at both ends of the reactor body 4; in addition, the The bottom of the reaction kettle body 4 is provided with a universal wheel 7; further, the reaction kettle body 4 is sealed and connected with the kettle cover 3; the electric heating rod 5 is provided with a temperature controller.

[0013] The paraffin reaction kettle provided by the present invention uses a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com