Mold core arbor for heterogeneous valve body

A non-homogeneous core bone technology, applied in the direction of core, mold box, mold, etc., can solve the problems of sand shooting obstruction, uncontrollable error, neglect of uneven deformation, etc., to achieve uniform and controllable deformation, uniform cross-sectional stress, The effect of reducing machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

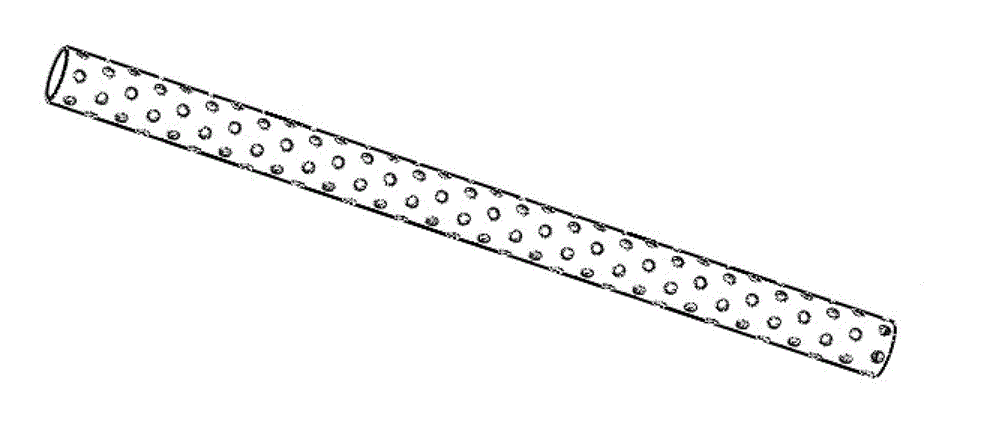

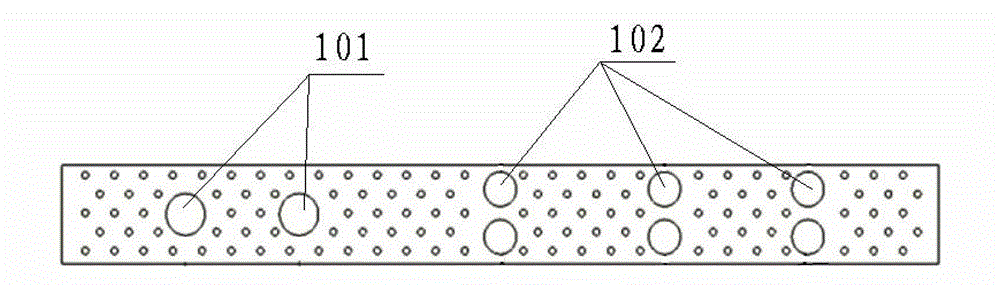

[0024] Such as image 3 As shown, a non-homogeneous valve body core core bone has a hollow tube core bone, and holes of uneven size and arrangement are opened on the wall body of the core bone. The holes with uneven size and arrangement include: multiple large holes are opened in multiple local areas on the wall of the core bone, and multiple small holes are opened in multiple other local areas on the wall of the core bone.

[0025] A plurality of large holes are opened in multiple local areas on the wall of the core bone—specifically: two large holes 101 arranged horizontally at intervals are opened on the front end of the wall body of the core bone, and there are holes from the middle to the rear end of the wall body of the core bone. Three rows of large holes arranged at intervals, each row of large holes includes two vertically arranged large holes three 102, the area of the large hole two 101 is greater than the area of the large hole three 102, the area of the larg...

specific Embodiment 2

[0026] Such as Figure 4 As shown, a non-homogeneous valve body core core bone has a hollow tube core bone, and holes of uneven size and arrangement are opened on the wall body of the core bone. The holes with uneven size and arrangement include: multiple large holes are opened in multiple local areas on the wall of the core bone, and multiple small holes are opened in multiple other local areas on the wall of the core bone.

[0027] A plurality of large holes are opened in multiple local areas on the wall body of the core bone—specifically: two large holes 201 arranged vertically are opened at the front end of the wall body of the core bone; Two large holes 5 202 arranged horizontally at intervals.

[0028] A plurality of small holes are opened in another partial area on the wall of the core bone, specifically: two small holes 203 arranged horizontally at intervals are opened in the interval between the two large holes 5 202, and the latter large hole 5 202 There are two sm...

specific Embodiment 3

[0030] Such as Figure 5 As shown, a non-homogeneous valve body core core bone has a hollow tube core bone, and holes of uneven size and arrangement are opened on the wall body of the core bone. The holes with uneven size and arrangement include: multiple large holes are opened in multiple local areas on the wall of the core bone, and multiple small holes are opened in multiple other local areas on the wall of the core bone.

[0031] A plurality of large holes are opened in a plurality of partial areas on the wall of the core bone—specifically: a plurality of rows of large holes with gradually changing areas are opened in local areas of the wall of the core bone VI.

[0032] A plurality of small holes are opened in another partial area on the wall of the core bone—specifically: a plurality of rows of small holes 4 with gradually changing areas are opened in another partial area of the wall of the core bone, and the cross-section of the six large holes is affected. The force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com