Medicinal compound rigid sheet for cold stamping forming

A composite hard sheet, cold stamping technology, applied in the direction of flexible coverings, packaging, layered products, etc., can solve the problems of stress imbalance, structural asymmetry, high scrap rate, etc., to avoid stress imbalance, high barrier Performance, the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

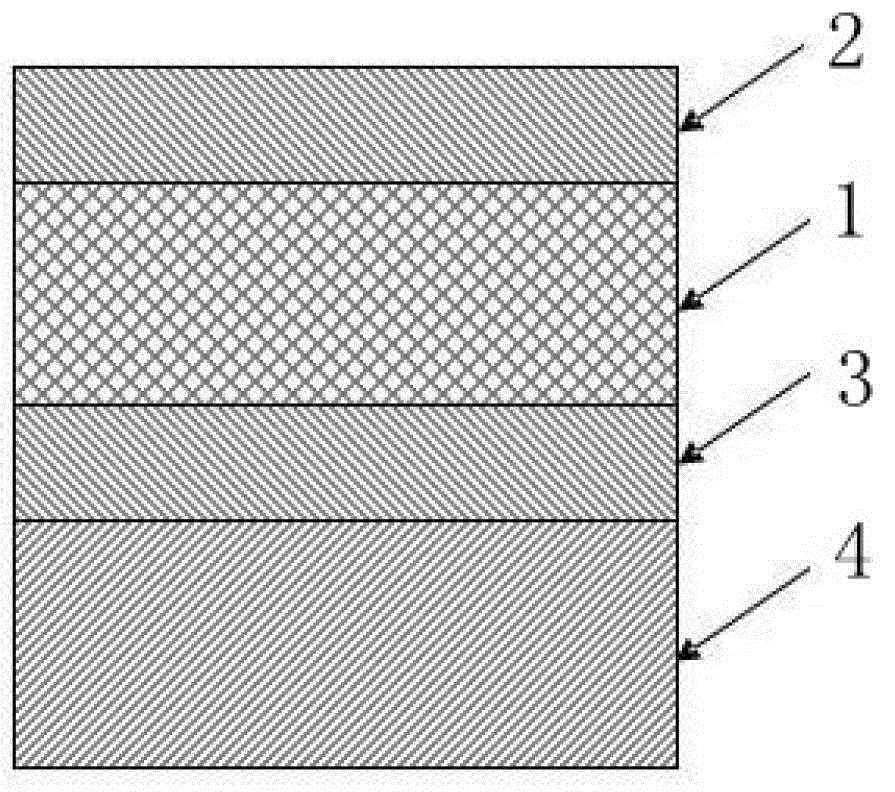

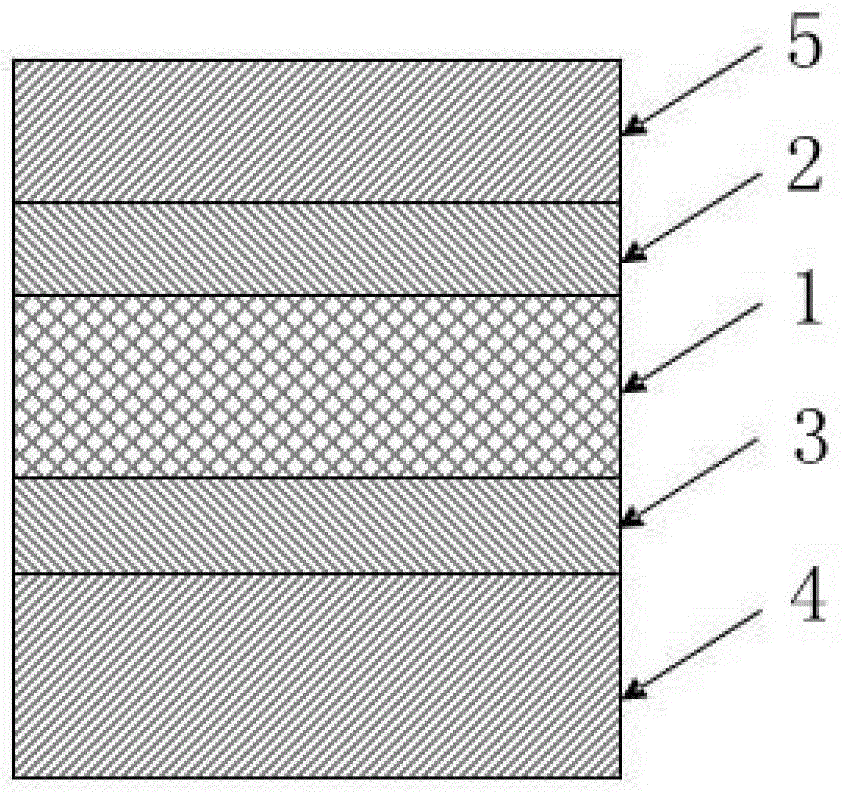

[0014] Combine below figure 1 , figure 2 The present invention is further described in detail so that those skilled in the art can implement it with reference to the description.

[0015] The cold stamping pharmaceutical composite hard sheet generally consists of three functional layers: the surface support strength layer, the middle aluminum foil barrier layer, and the inner surface heat sealing layer. The layers are bonded together by bonding to form a solid composite film. The surface support strength layer of cold stamping pharmaceutical composite hard sheet requires smoothness, good transparency, high mechanical strength, excellent impact resistance, and certain wear resistance and puncture resistance, which is mechanically important to the entire packaging. protective effect. Therefore, the surface support layer uses a biaxially oriented nylon film (BOPA) layer with high strength, excellent impact resistance and high barrier properties to replace the traditional poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com