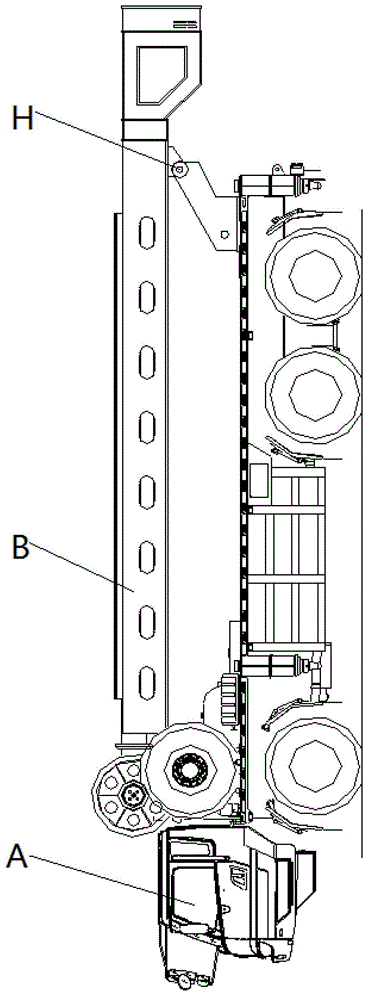

System and method for operation control of vehicle-mounted drill machine

A control system and technology for drilling rigs, which are applied to the automatic control system of drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of operation safety impact, vehicle movement, complicated control methods, etc., and improve operation safety. , to avoid the effect of vehicle swaying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

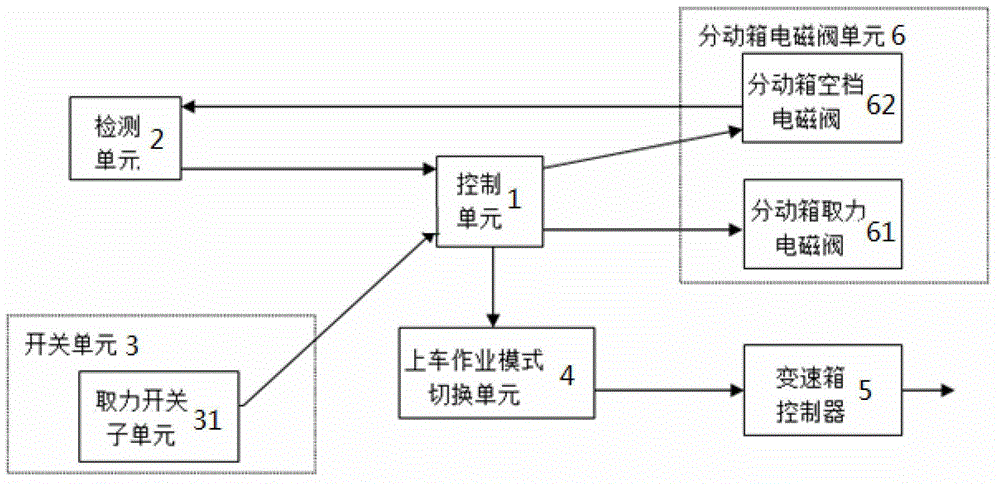

[0037] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

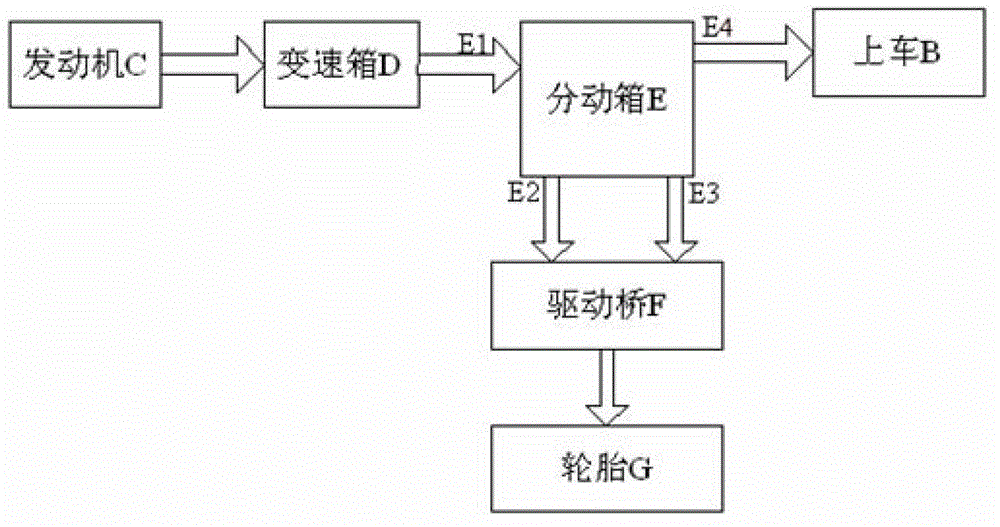

[0038] image 3 It is a schematic diagram of the principle of the first embodiment of the vehicle-mounted drilling rig operation control system provided by the present invention. Such as image 3 As shown, the vehicle-mounted drilling rig operation control system provided by the present invention includes a control unit 1, a detection unit 2, a switch unit 3, a boarding operation mode switching unit 4, a gearbox controller 5 and a transfer case solenoid valve unit 6, wherein:

[0039] Control unit 1 can adopt PLC (ProgrammableLogic Controller, programmable logic controller) well-known to those skilled in the art, and PLC can pass the signal such as input switching quantity, analog quantity through certain program design, according to established logical output control solenoid valve, Executive elements such as lights...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com